Movable arm energy-saving system adopting variable-diameter balanced hydraulic cylinder

A technology for balancing hydraulic cylinders and energy-saving systems, applied to mechanically driven excavators/dredgers, etc., can solve problems such as energy waste, heavy weight of hydraulic excavator working devices, and system temperature rise, so as to improve system stability and improve Effects of energy recovery efficiency and efficient reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

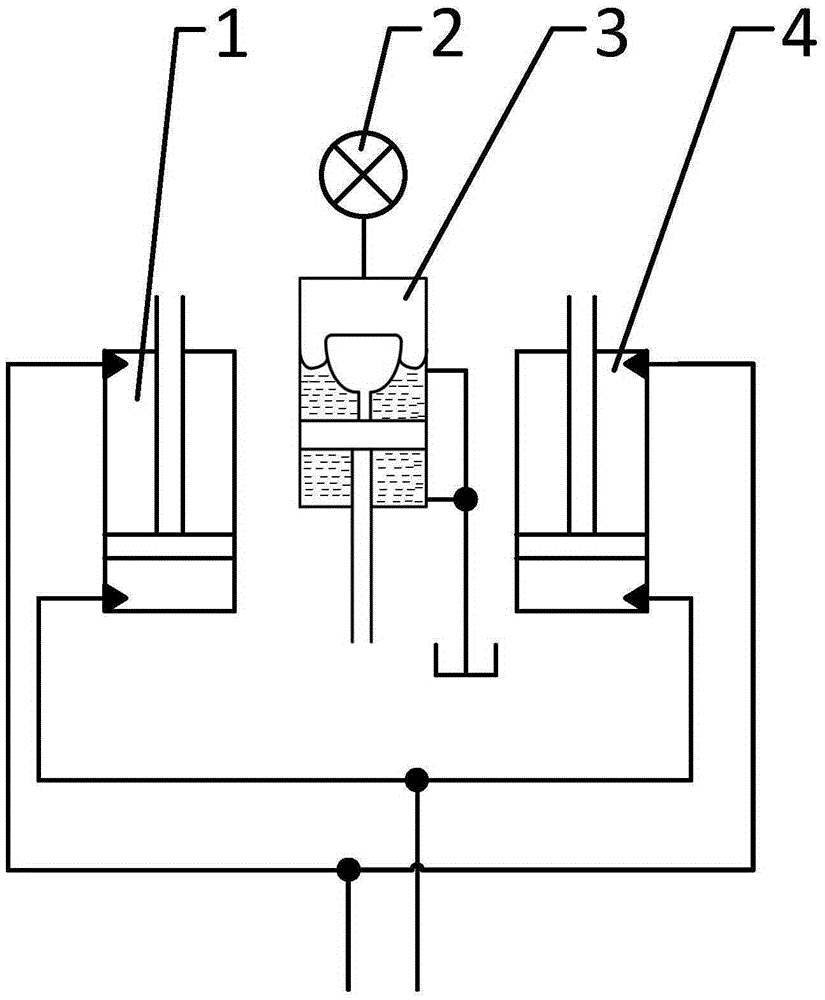

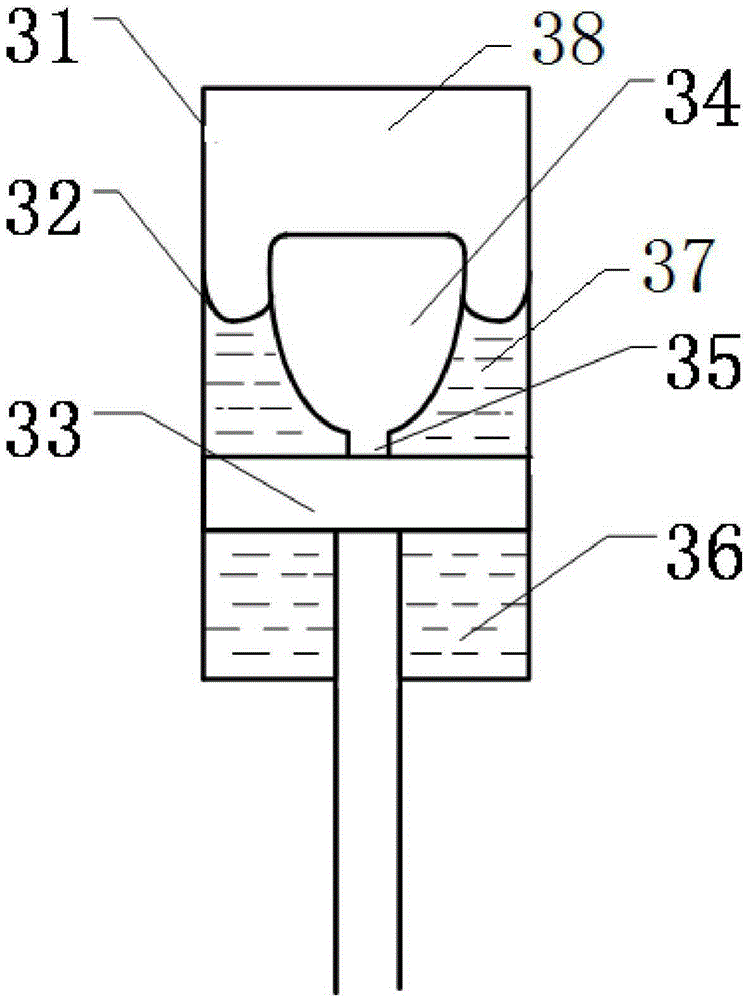

[0014] like figure 1 and figure 2 A boom energy-saving system using a variable diameter balance hydraulic cylinder as shown includes a variable diameter balance hydraulic cylinder 3, a first prime boom hydraulic cylinder 1 and a second prime boom hydraulic cylinder 4; the first prime boom hydraulic cylinder The rodless cavity of 1 is communicated with the rodless cavity of the second prime boom hydraulic cylinder 4; the rod cavity of the first prime boom hydraulic cylinder 1 is communicated with the rod cavity of the second prime boom hydraulic cylinder 4; the diameter is balanced The hydraulic cylinder 3 is connected with the pressure gauge 2; the variable diameter balance hydraulic cylinder 3 includes a casing 31, an elastic diaphragm 32 is arranged in the casing 31, a push rod 34 with an inclined surface is arranged under the elastic diaphragm 32, and the push rod 34 is connected with a piston 33; the piston 33 is connected with a piston rod; above the elastic diaphragm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com