Integrated construction method of piled cofferdam platform for low pile caps in rock formations

A technology of rock strata and construction method, applied in basic structure engineering, construction and other directions, can solve the problems of long construction period, difficult to meet construction requirements, and huge input of manpower and material resources, achieving small excavation area and square volume, saving manpower , the effect of speeding up the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

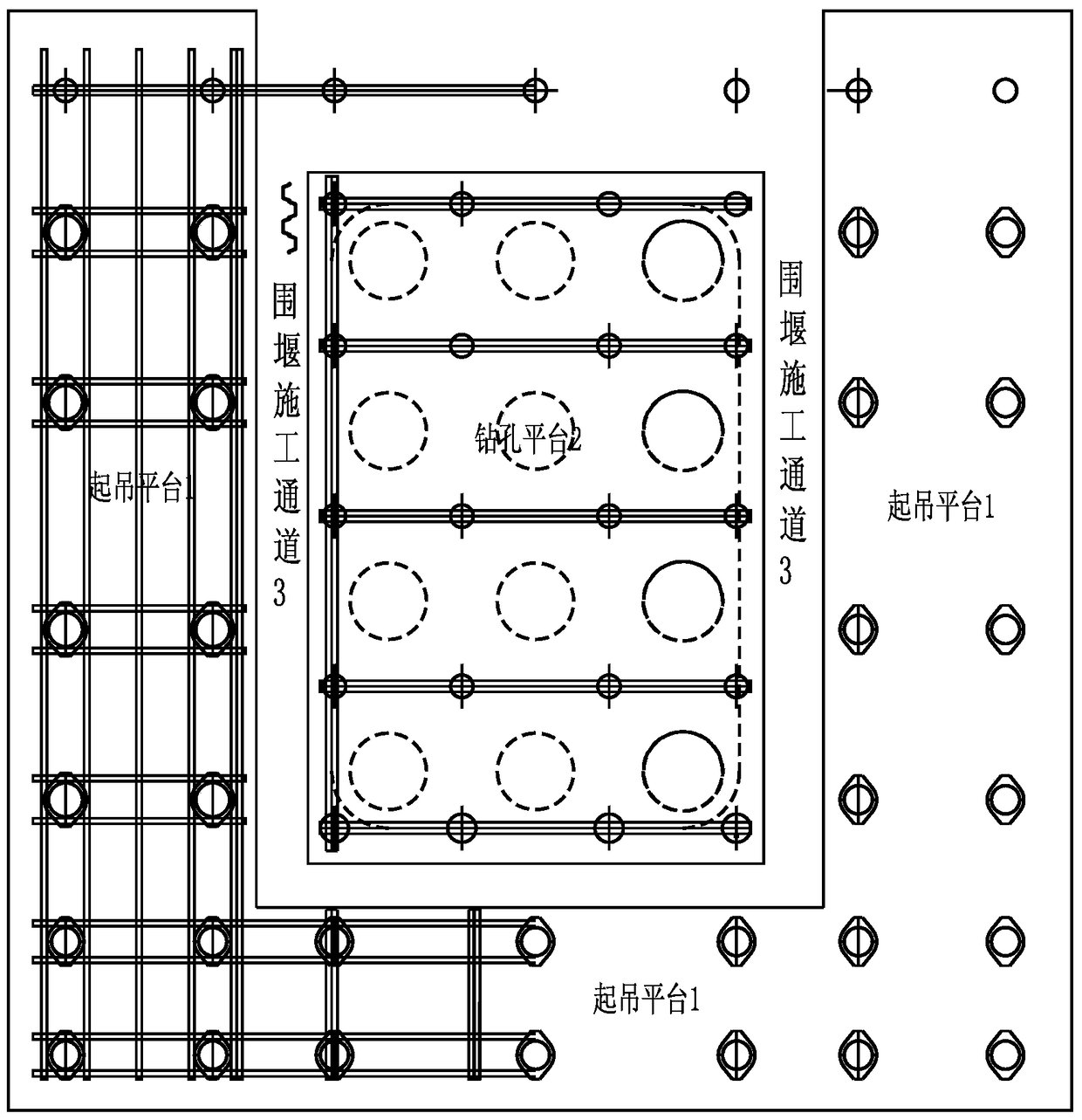

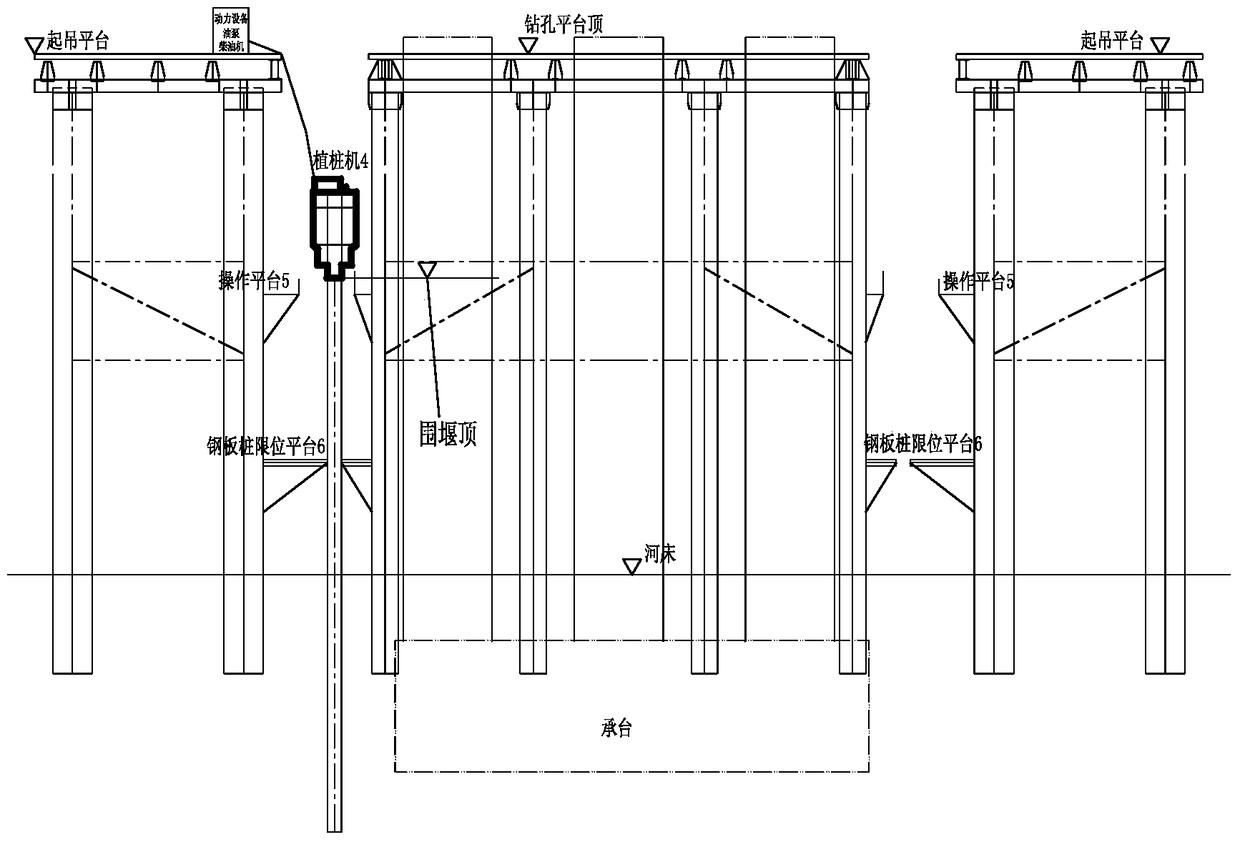

[0021] See figure 1 As shown, the integrated construction method of pile-planting cofferdam platform for low pile caps in rock formations in the embodiment of the present invention includes the following steps:

[0022] S1: Simultaneous construction of lifting platform 1 and drilling platform 2 on the rock formation, lifting platform 1 is located around drilling platform 2; during the construction of lifting platform 1 and drilling platform 2, the lifting platform 1 and drilling platform The cofferdam construction channel 3 is reserved between 2 and the cofferdam platform panel is laid on the cofferdam construction channel 3 to serve as the cofferdam construction platform and drilling platform, and go to S2.

[0023] S2: Cofferdam construction is performed on the drilling platform 2 on the cofferdam construction platform, and at the same time, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com