Starch filtrate reducer for drilling fluid and preparing method thereof

A fluid loss control agent and drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as the inability to fully meet the requirements of drilling fluid reservoir protection, achieve easy implementation and popularization, reduce filtration The effect of good failure effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

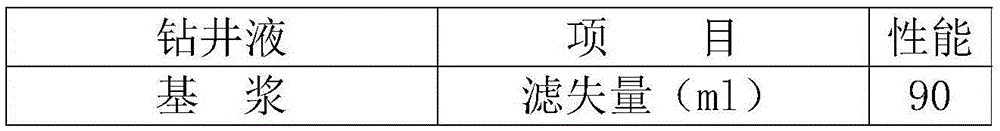

Image

Examples

preparation example Construction

[0023] The preparation method of an embodiment of the above-mentioned starch fluid loss reducer for drilling fluid comprises the following steps:

[0024] Take each raw material by mass parts;

[0025] The raw materials are uniformly mixed to obtain the starch fluid loss reducer for drilling fluid. Mixing can be performed in a kneader.

[0026] The preparation method of another embodiment of the above-mentioned starch fluid loss reducer for drilling fluid comprises the following steps:

[0027] Slurry preparation: put an appropriate amount of water in a container, measure the total mass of water and water as 100 parts, add 20-30 parts of starch, then add high-temperature stabilizer and alkalinity regulator in sequence according to the proportion, and mix to form a slurry . In the slurry preparation step, 20-30 parts by mass of starch are added, and 90-99 parts in the starch fluid loss control raw material. For example, 20-30 parts of starch are added to 70-80 parts by mass...

Embodiment 1

[0032] The following raw materials were weighed in parts by mass: 70 parts of potato starch, 20 parts of tapioca starch, 7 parts of canna starch, and 3 parts of magnesium oxide.

[0033] Mix uniformly with a kneader to obtain the starch fluid loss reducer for drilling fluid.

Embodiment 2

[0035] Weigh the following raw materials in parts by mass: 60 parts of potato starch, 30 parts of tapioca starch, 5 parts of canna starch, 7 parts of betel nut starch, and 5 parts of magnesium oxide.

[0036] Mix uniformly with a kneader to obtain the starch fluid loss reducer for drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com