Whole-body polished porcelain tile having three-dimensional stone texture and production method of tile

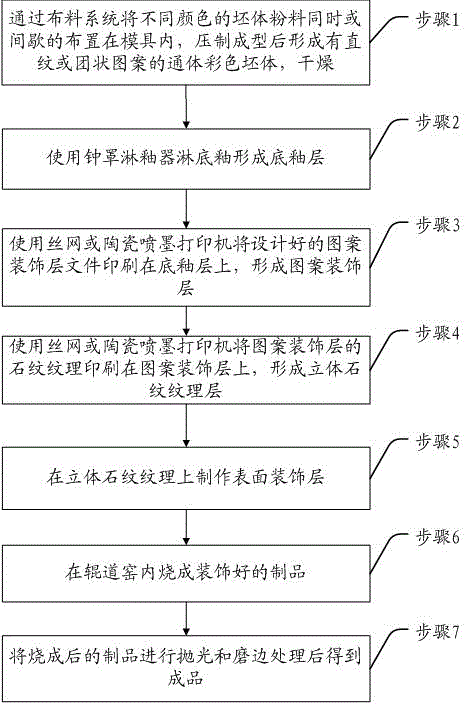

A manufacturing method and a technology for porcelain tiles are applied in the production field of glazed porcelain tiles, which can solve the problems such as the inability to realize continuous and changeable three-dimensional stone grain texture, and achieve the effects of rich texture changes, protection of the natural environment, and strong decorative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

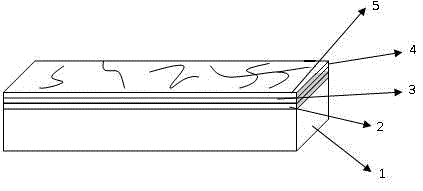

[0056] The product produced in this embodiment is a full-body full-glazed porcelain tile imitating gray wood-grained sandstone, including a full-body straight-grained colored body (brick), a bottom glaze and a transparent glaze.

[0057] The chemical composition of the base green body is specifically as follows by weight percentage:

[0058] SiO 2 :68.1~69.5%,Al 2 o 3 : 18.3~19.2%, CaO: 0.3~0.6%, MgO: 0.7~1.0%, K 2 O:3.3~3.6%,Na 2 O:1.4~1.7%, Fe 2 o 3 : <1%. Green body water absorption <0.5%.

[0059] The glaze chemical composition of bottom glaze is specific as follows by weight percentage:

[0060] SiO 2 :63.9~69.2%,Al 2 o 3 : 18.3~20.1%, CaO: 0.8~1.3%, MgO: 0.5~0.7%, BaO: 0.5~0.7%, K 2 O:0.1~0.5%,Na 2 O:3.7~4.3%,ZnO:0.2~0.5%,ZrO 2 :2.9~9.7%,Fe 2 o 3 : <0.4%.

[0061] The chemical composition of the glaze material of the transparent glaze is specifically as follows by weight percentage:

[0062] SiO 2 :48.7~52.3%,Al 2 o 3 : 17.6~19.3%, CaO: 7.2~8.7%, MgO...

Embodiment 2

[0074] The product produced in this embodiment is a matte polished glazed porcelain tile imitating apricot-colored Oman beige stone, including a whole-body lump texture body (brick body), a bottom glaze and transparent dry particles.

[0075] The chemical composition of the base green body is specifically as follows by weight percentage:

[0076] SiO 2 :65.8~68.3%,Al 2 o 3 : 19.7~21.1%, CaO: 0.2~0.5%, MgO: 0.5~0.7%, K 2 O:3.1~3.3%,Na 2 O:0.8~1.3%, Fe 2 o 3 : <1%. Green body water absorption <0.5%.

[0077] The glaze chemical composition of bottom glaze is specific as follows by weight percentage:

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com