LED lamp band rolling device

A technology of LED light strips and winding devices, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of reduced production efficiency and low winding efficiency, and achieve the improvement of winding efficiency and connection Quick and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

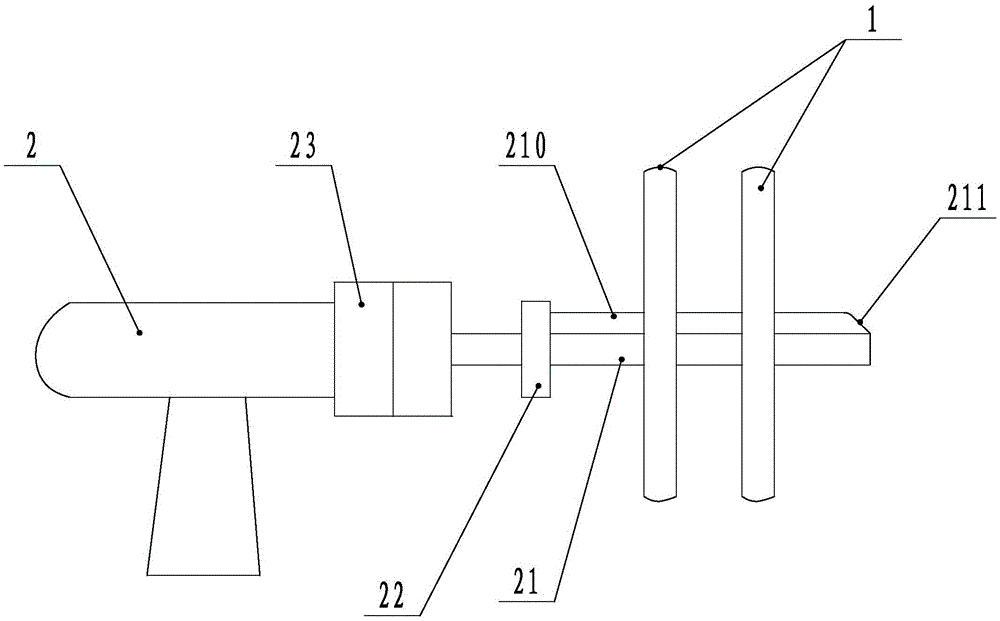

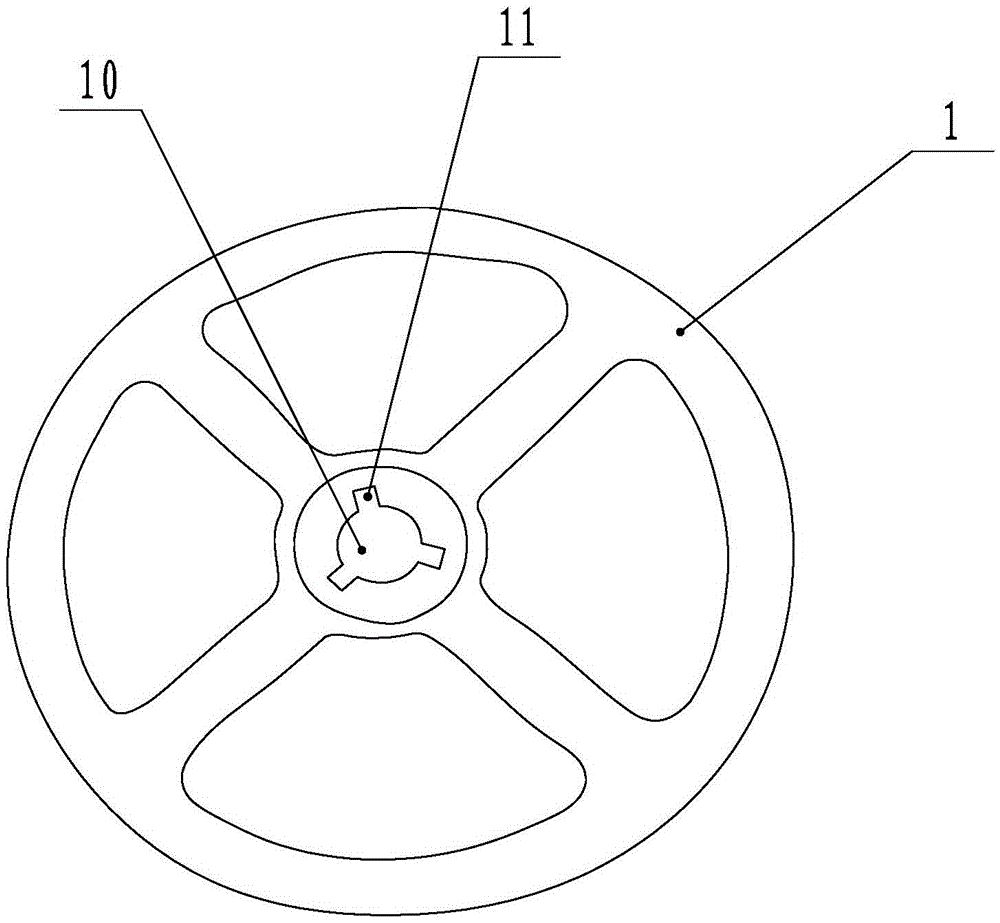

[0015] refer to figure 1 and figure 2 , a LED light strip winding device of the present invention, comprising a winding reel 1 and a driving mechanism 2, the driving mechanism 2 is provided with a rotating shaft 21, the end of the rotating shaft 21 is formed with a rib 210, and the middle of the winding reel 1 is provided with a The socket hole 10 adapted to the rotating shaft 21, the socket hole 10 is formed with a card slot 11 compatible with the rib 210, and the winding reel 1 is clamped on the rib 210 through the card slot 11 so as to be installed and connected to the On the rotating shaft 21, a limit block 22 is arranged in the middle of the rotating shaft 21. The limit block 22 protrudes outward along the circumferential direction of the rotating shaft 21. The limit block 22 is cylindrical and is used to limit the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com