Express sorting machine comprising cam and worm for driving

A worm drive and sorter technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of affecting the transmission accuracy, the chain is easy to stretch, the goods are displaced, etc., to achieve good conveying effect, avoid friction and easy Wear, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

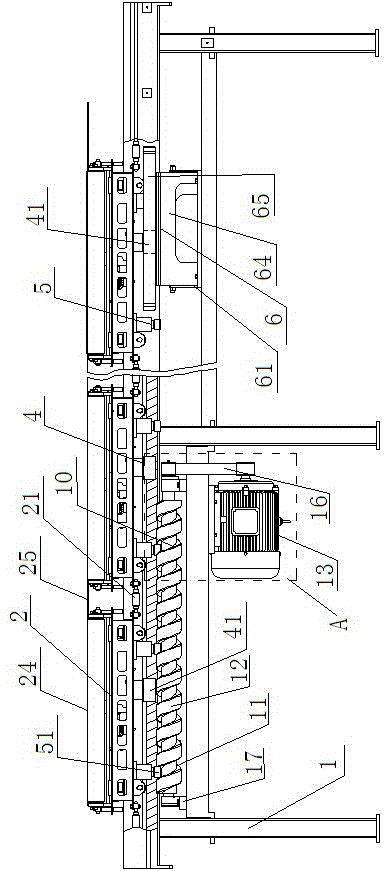

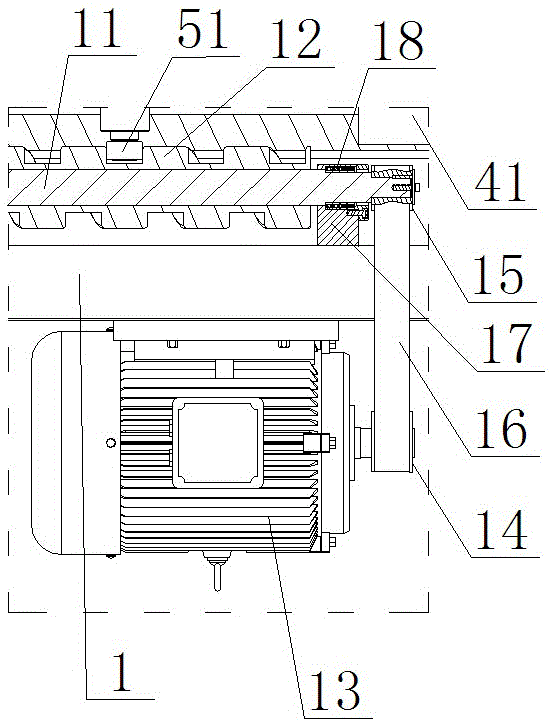

[0029] see Figure 1 ~ Figure 3 , The present embodiment includes a frame 1, a plurality of cars 2, and a car driving device 10. The cars 2 are installed on the frame 1, and the cars 2 are connected by universal joints 21; the car driving device 10 is installed on the frame 1.

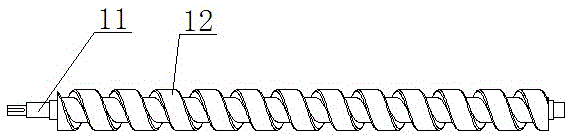

[0030] The trolley driving device 10 includes a worm 11, a cam 12 and a worm driving device. The cam 12 is spirally fixed on the worm 11, the worm driving device is fixed on the frame 1, and the worm driving device is connected with the worm 11. The worm driving device drives the worm 11 to rotate, and the cam 12 pushes the trolley 2 forward during the rotation, thereby controlling the operation of the trolley 2 .

[0031] Worm driving device comprises motor 13, No. 1 pulley 14, No. 2 pulley 15, and motor 13 is fixed on the frame 1, and No. 1 pulley 14 is fixed on the motor 13 shaft of motor 13, and No. 2 pulley 15 and worm One end of 11 is fixed, and is connected by belt 16 between No. 1 pulley 14 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com