A slag chip transfer box convenient for forklift handling and dumping and its operation method

A transfer box, forklift technology, applied in the directions of transportation and packaging, containers, packaging, etc., can solve the problems of iron box dumping easily damaged and deformed, unsuitable for slag storage and transportation, unsafe hidden dangers, etc., to improve the smooth dumping. The effect of preventing the problem of subsidence and avoiding crush damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

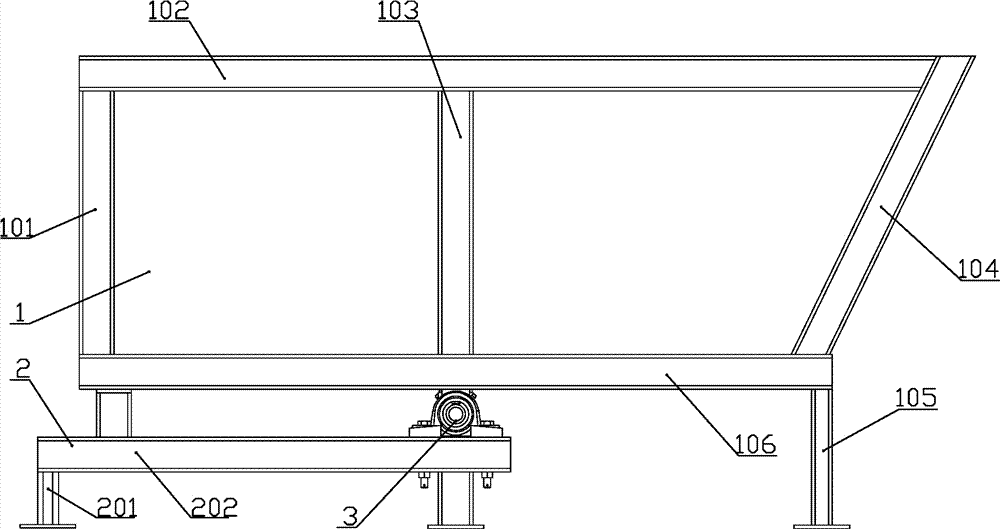

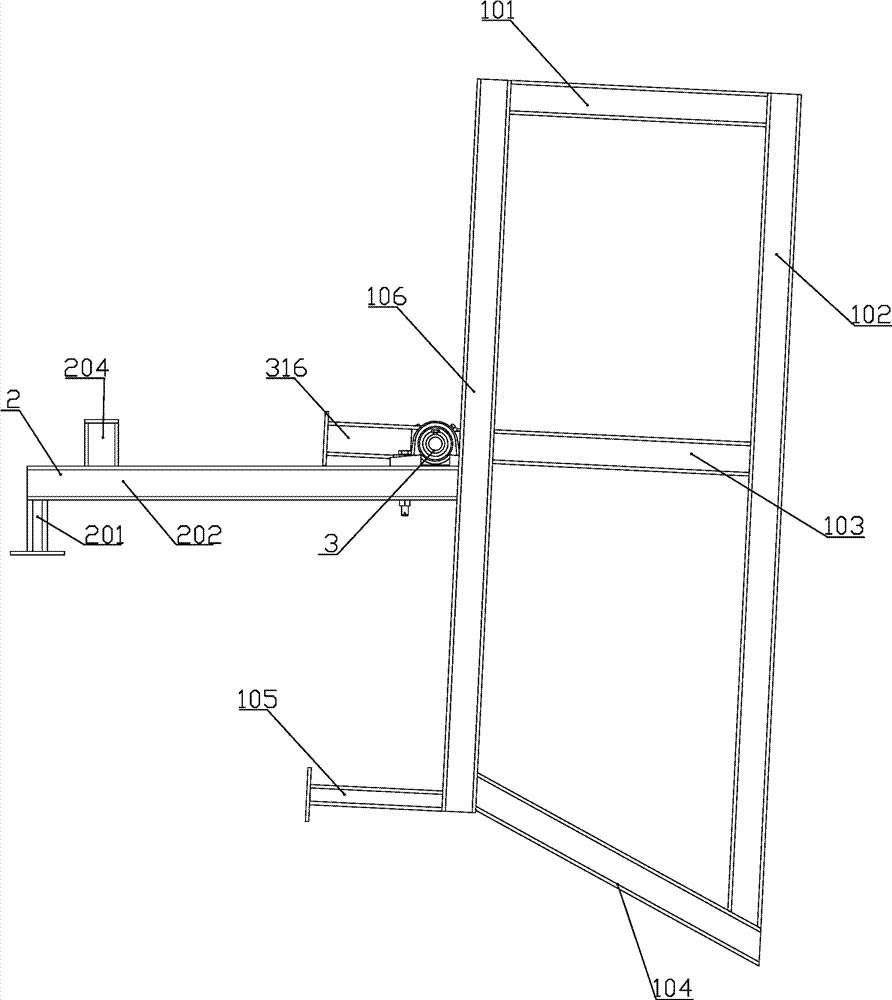

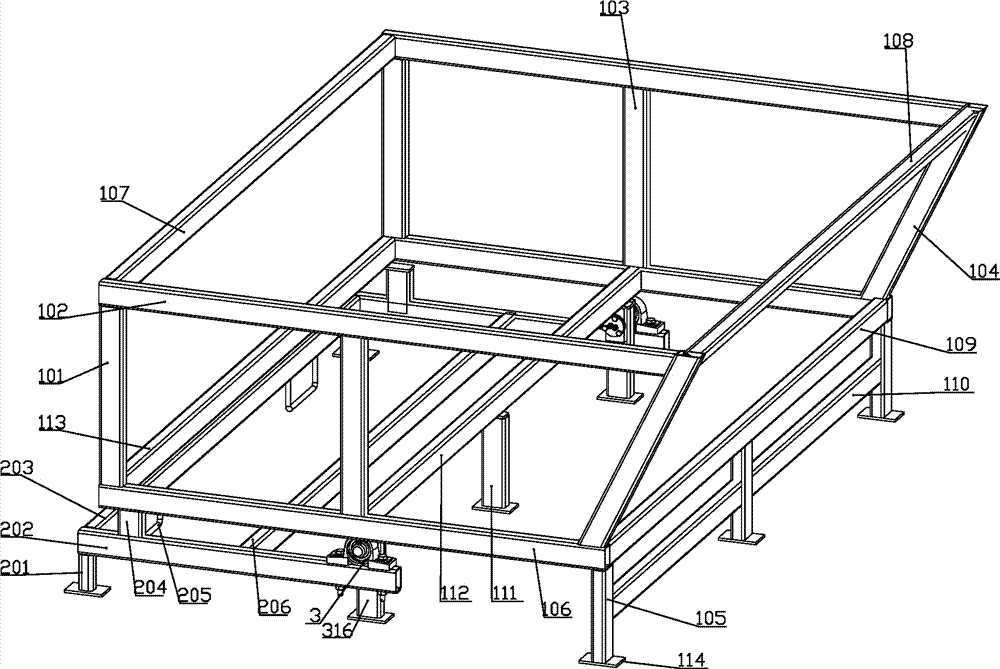

[0048] Such as Figure 1-8 As shown, a slag transfer box that is convenient for forklift handling and dumping includes a box mechanism 1, and its feature is that the box mechanism 1 is rotatably connected to the frame mechanism 2 through a hinge mechanism 3. In order to realize the reversible connection between the box mechanism 1 and the frame mechanism 2, the hinge mechanism 3 is used to connect them to facilitate subsequent automatic reversing.

[0049] Further, in order to realize the automatic overturning of the box mechanism 1, and at the same time effectively store the small-volume water-mixed-oil-mixed slag without leakage, the efficiency of the transfer and dumping of the unit small-volume water-oil-mixed slag can be greatly improved. Convenience, using the following box structure design. The box mechanism 1 includes a frame body structure and a frame panel. The frame body structure includes a No. 1 beam 113, and the No. 1 beam 113 is welded to two No. 2 beams 106. ...

Embodiment 2

[0066] Using the operation method and working process of the above-mentioned slag and chip transfer box in conjunction with a forklift, an operation method for a slag and chip transfer box that is convenient for forklift handling and dumping: it includes the following steps, the first step is to place the slag and chip transfer box stably The location where the slag is collected. When the box is full of slag and needs to be transferred, the forklift operator drives the forklift 4 to the slag transfer box, and inserts the fork 6 of the fork lift platform 5 into the fork of the frame mechanism 2. Inside the ear 205, until the front end of the pallet fork 6 reaches the bottom of the No. 7 beam 110 of the box mechanism 1.

[0067] In the second step, by starting the forklift 4, the forklift lifting platform 5 will drive the slag transfer box and the internal slag to rise together, and start the forklift 4 to smoothly transfer the slag to the place where it needs to be dumped.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com