Furnace infrared thermometer shield protection device

An infrared thermometer and infrared temperature measurement technology, applied in the field of infrared thermometers, can solve problems such as using infrared thermometers, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

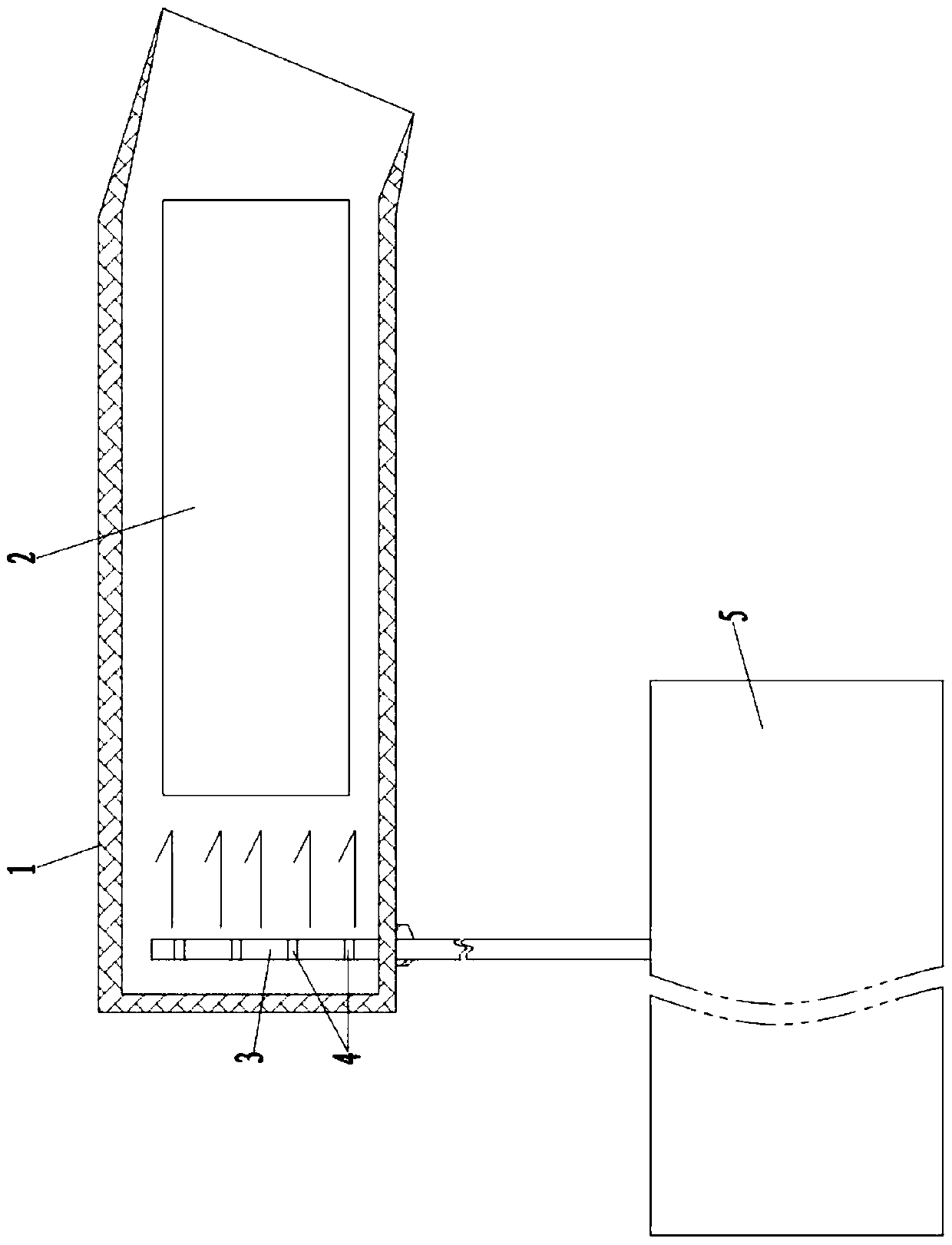

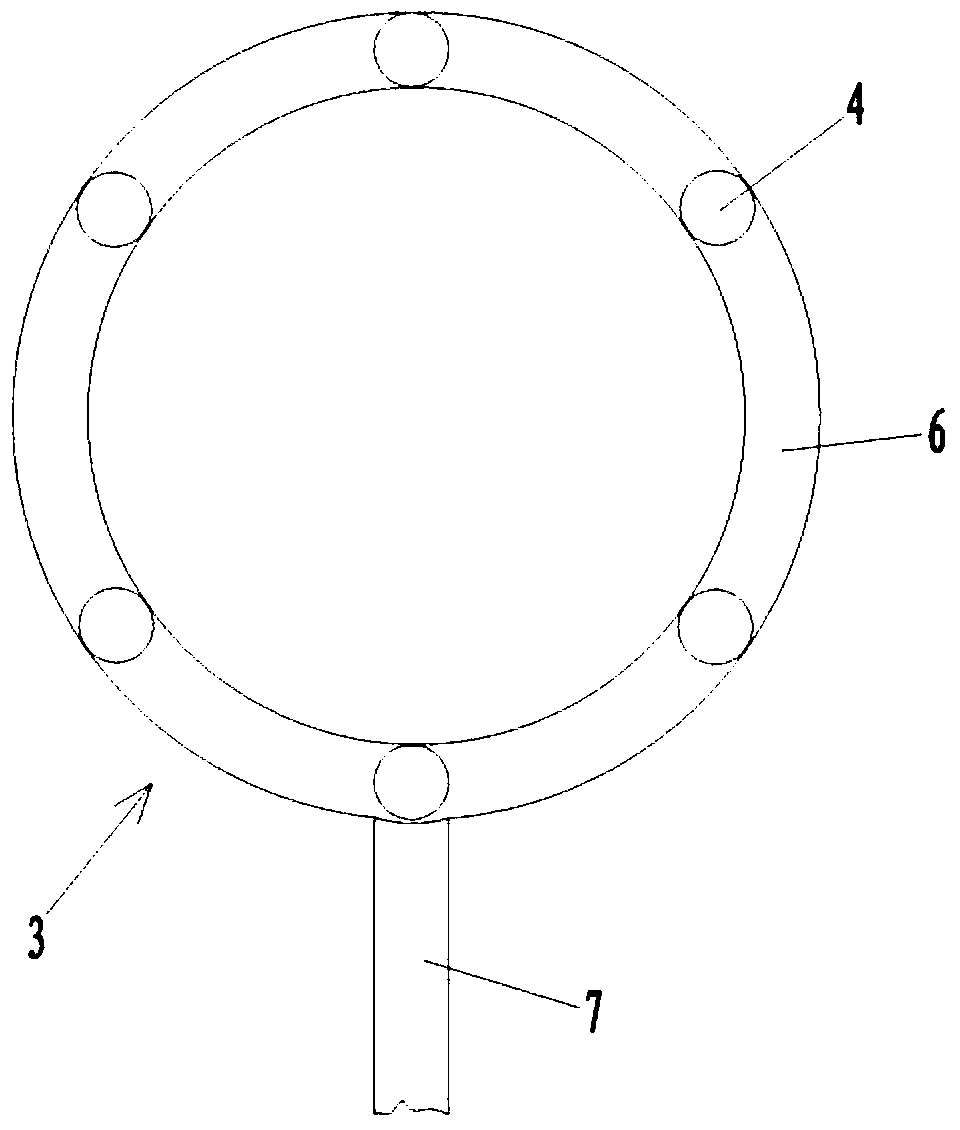

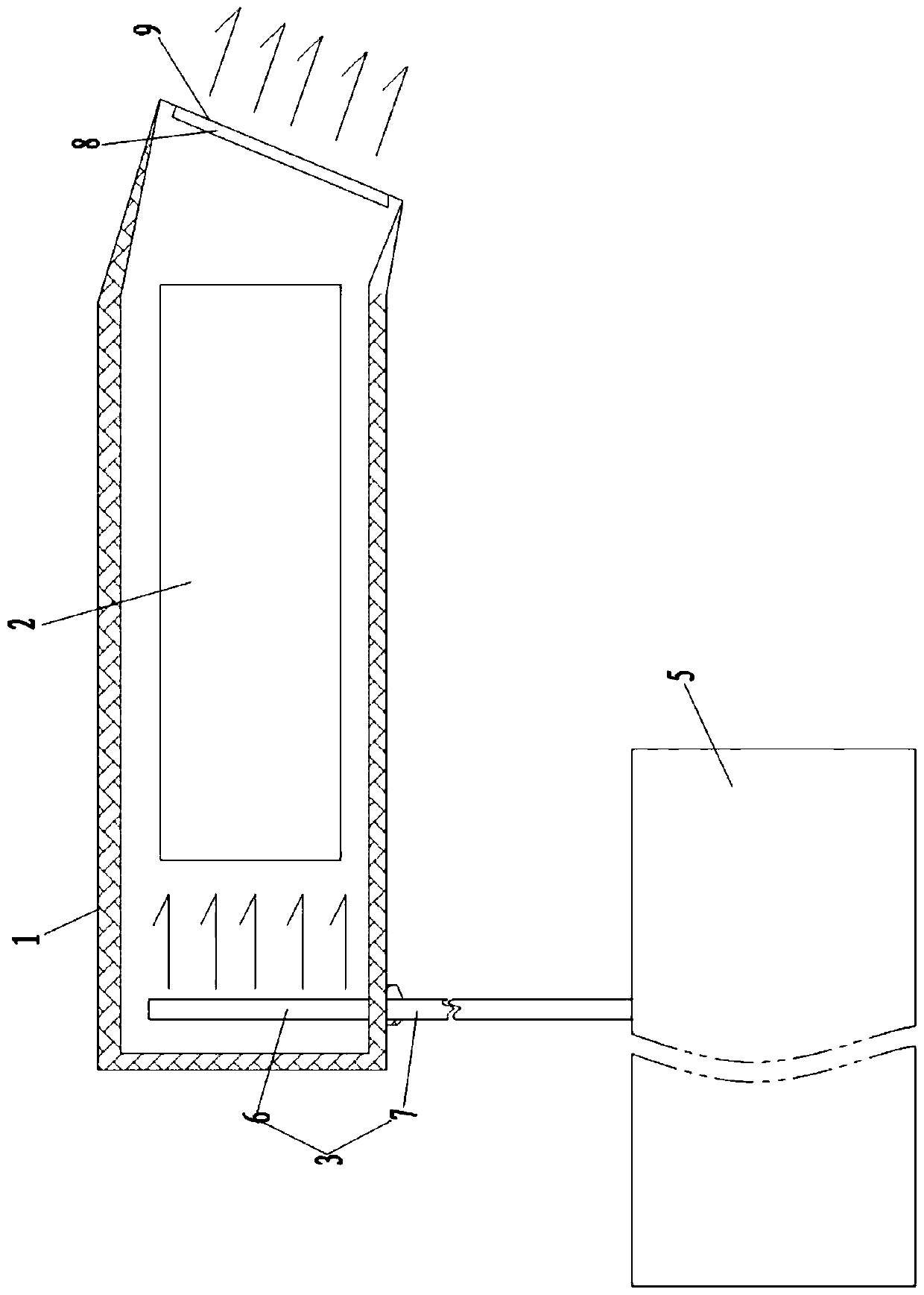

[0030] Such as figure 1 The schematic diagram of the first embodiment of the furnace infrared thermometer shield device of the present invention includes at least one heat preservation cover 1, and the heat preservation cover 1 is made of double-layer stainless steel pipe and cast aluminum end cover, which has a relatively Good corrosion resistance and heat preservation ability, can continuously measure temperature in high temperature and heavy dust environment. In this embodiment, five thermal insulation covers 1 are arranged, and each thermal insulation cover 1 is placed horizontally, and an infrared thermometer 2 is respectively placed in the inner cavity of each thermal insulation cover 1, and the infrared thermometer 2 is controlled by an external electrical control device. To control its work, the inner cavity of each heat preservation cover body 1 is respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com