Accelerator console control mechanism

A control mechanism and accelerator platform technology, which is applied to aircraft parts, aircraft power units, transportation and packaging, etc., can solve the problems of time-consuming and labor-intensive, prone to fatigue, low comfort of operating the throttle handle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and functions of the throttle platform operating mechanism proposed according to the present invention will be described in detail as follows.

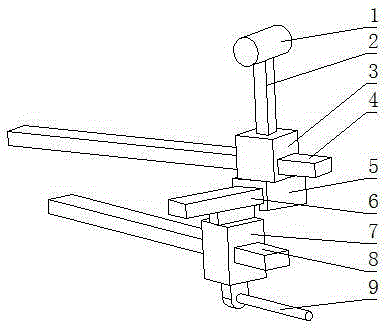

[0015] see figure 1 , the throttle platform operating mechanism of the present invention includes a throttle handle 1 and a flexible shaft joint 9, wherein: a throttle lever 2 is fixedly installed under the throttle lever 1, and a slider A3 is fixedly connected to the lower part of the throttle lever 2, and the slider A3 is slidably set On the guide rail A4, the slider B5 is fixedly connected under the slider A3, the slider B5 is slidably set on the guide rail B6, the lower part of the guide rail B6 is fixedly connected with the slider C7, and the slider C7 is slidably set on the guide rail C8, A flexible shaft joint 9 is fixedly connected to the slide block C7. The centerlines of guide rail A4 and gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com