A double-plate bilge keel and its installation method

An installation method and bilge keel technology, applied in the field of hull assembly, can solve the problems of increased labor intensity, waste of manpower and material resources, etc., and achieve the effect of reducing labor intensity, reducing waste, and easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

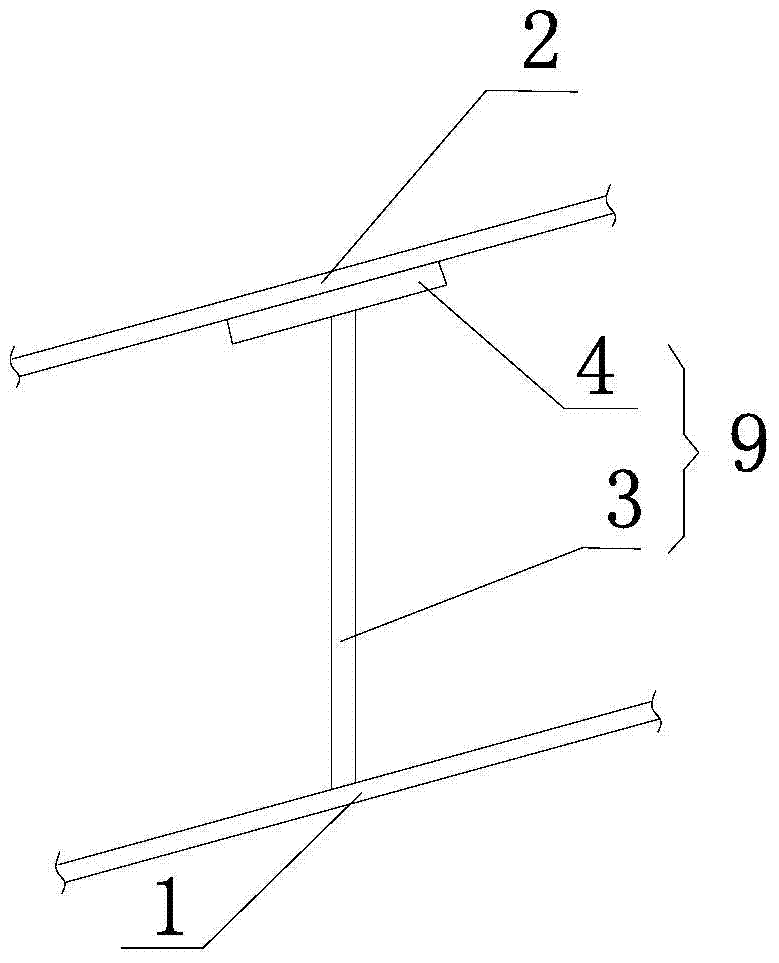

[0028] Such as figure 1 As shown, the double-plate bilge keel of the present invention includes an upper plate 2, a lower plate 1, a number of panels 4 and a number of reinforcing ribs 3. The upper end of a reinforcing rib 3 is connected with a panel 4 to form a "T" shape Part 9, the lower end of the reinforcing rib 3 is connected to the lower plate 1, and the "T"-shaped part 9 is located between the upper plate 2 and the lower plate 1. The reinforcing rib 3 has a longitudinal angle with the face plate 4, the upper plate 2 and the lower plate 1.

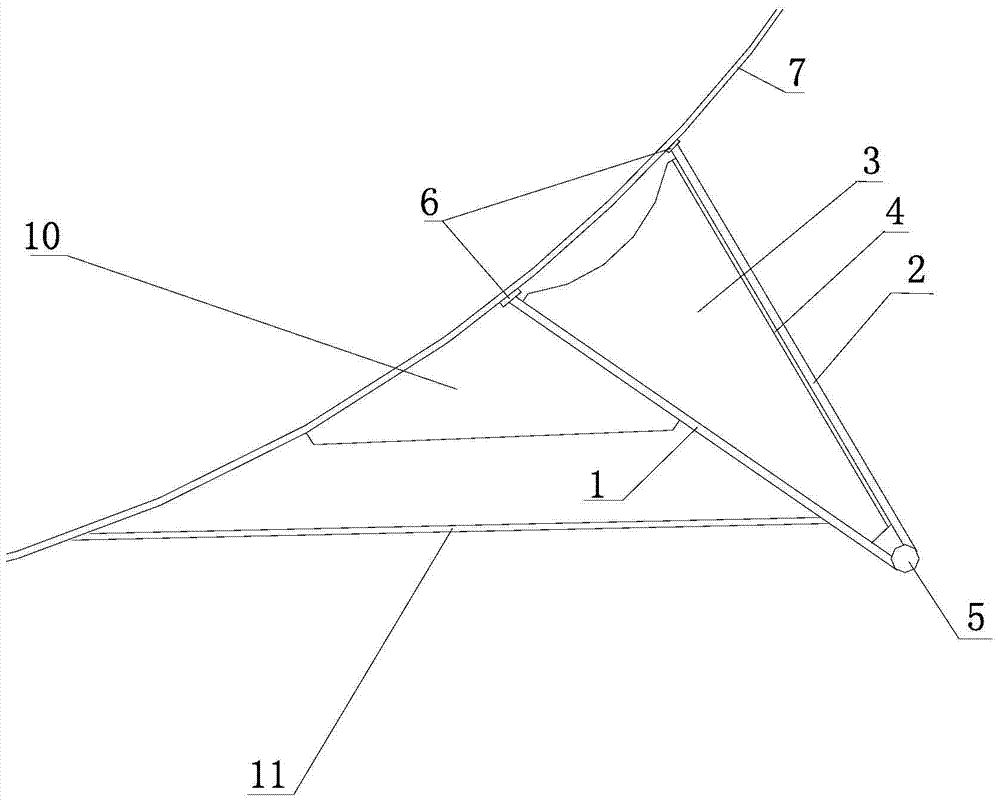

[0029] Such as image 3 As shown, the double-plate bilge keel also includes two backing plates 6, which are divided into an upper backing plate 62 and a lower backing plate 61. The backing plate 6 is installed on the hull shell, and one end of the upper plate 2 is installed on the upper backing On the plate 62, one end of the lower plate 1 is installed on the lower backing plate 61, and the other end of the upper plate 2 and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com