Positioning and clamping device for glass machining

A positioning and clamping, glass technology, applied in the direction of stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems affecting the quality of glass products, glass displacement, different shapes, etc., to achieve fast and accurate positioning, improve product quality, improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

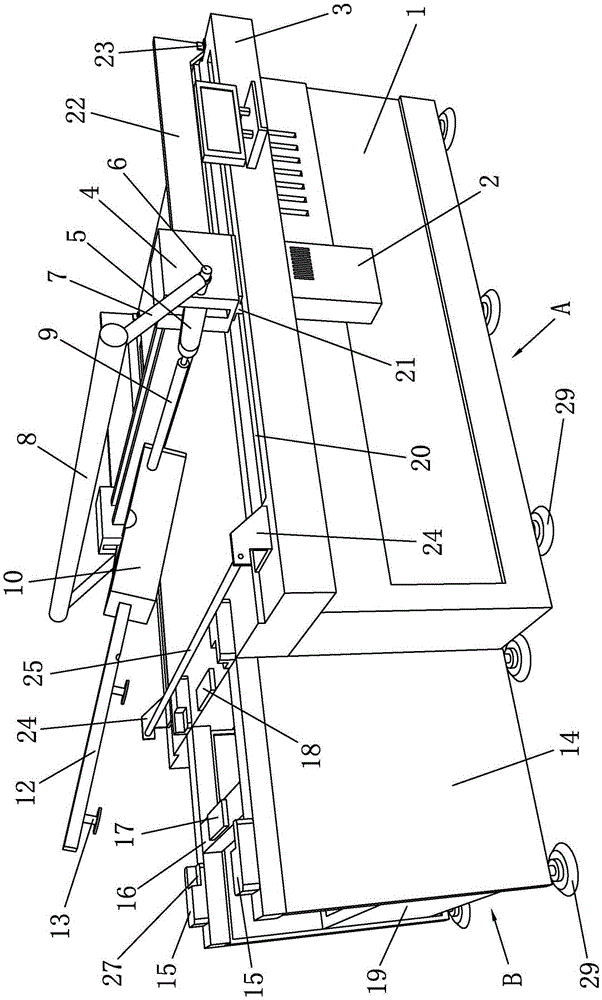

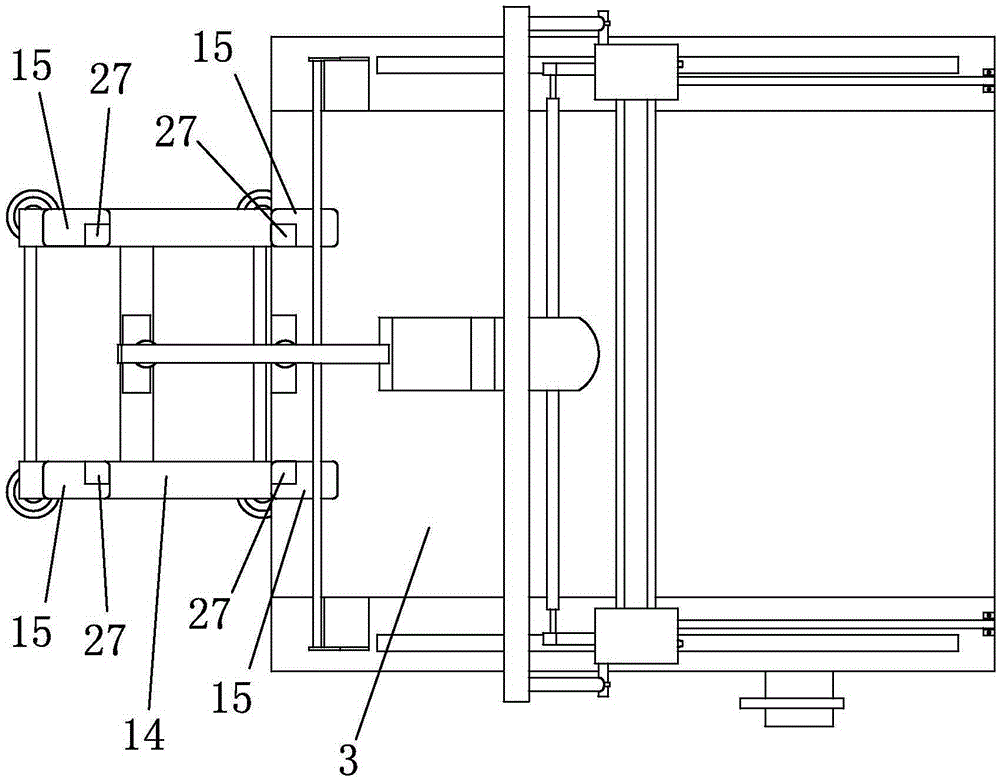

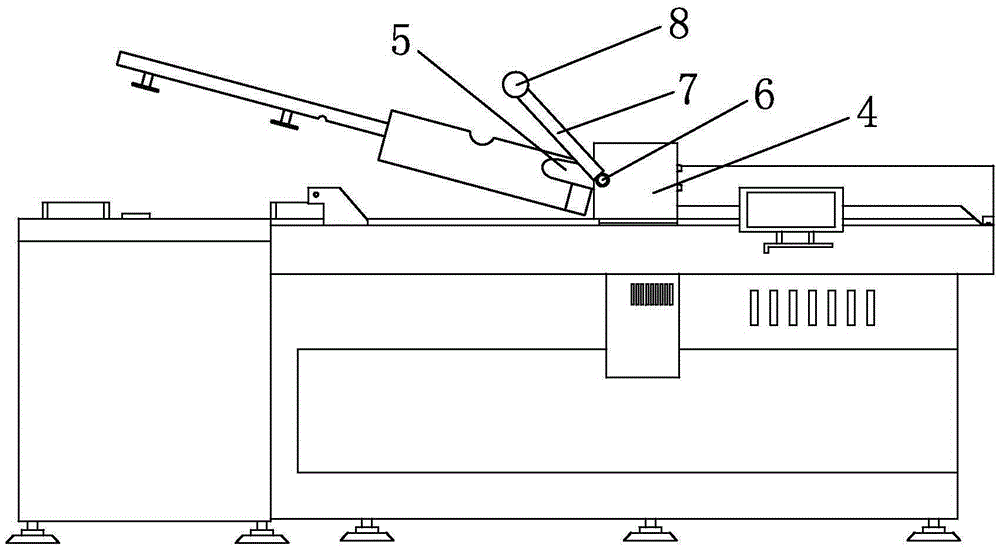

[0025] Such as Figure 1 to Figure 7 As shown, it is a positioning and clamping device for glass processing according to the present invention, which includes a body 1 and a power supply box 2 arranged on the body 1. The power supply box 2 is connected to an external power supply through a wire, and a 220V power supply is used to supply power to the body 1. . Body 1 is provided with workbench 3, is provided with fixed base 4 on workbench 3, is provided with a rotating space in fixed base 4, is provided with rotating arm 5 in fixed base 4, and rotating arm 5 moves in the rotating space, and rotating arm 5 is provided with a rotating shaft 6, and the rotating shaft 6 is arranged on the fixed base 4. The rotating shaft 6 is provided with a connecting rod 7, and a driving handle 8 is arranged between the connecting rods 7. The rotation of the rotating arm 5 is mainly realized by pressing the driving handle 8 artificially. , in order to increase the friction on the driving handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com