Positioning assisting frame

A positioning aid and frame technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve laborious and laborious problems, and achieve the effect of low cost, wide use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

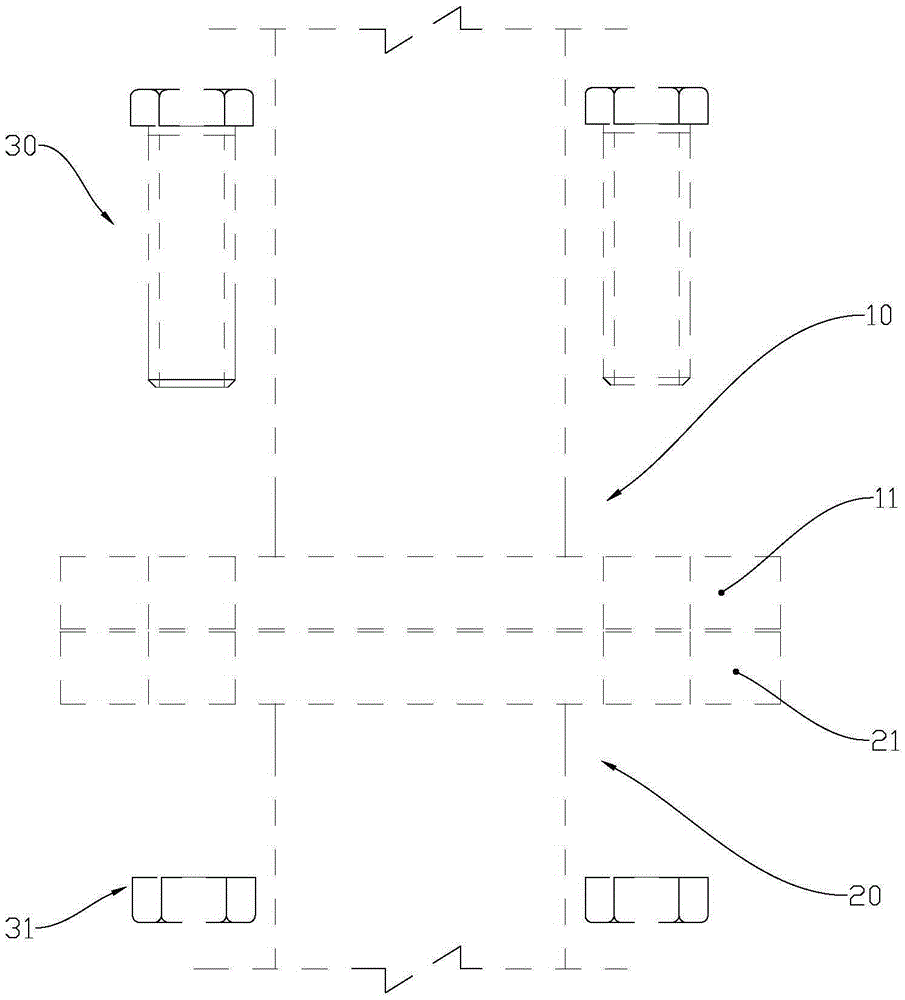

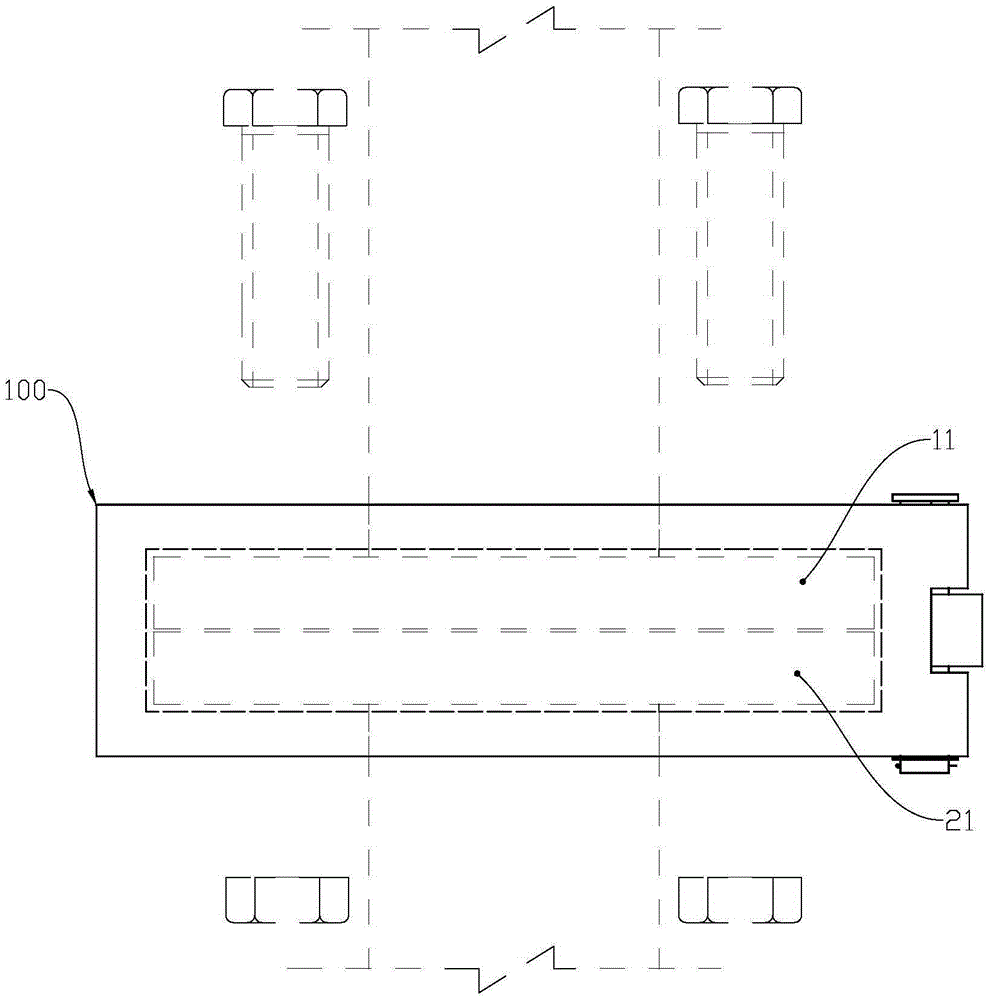

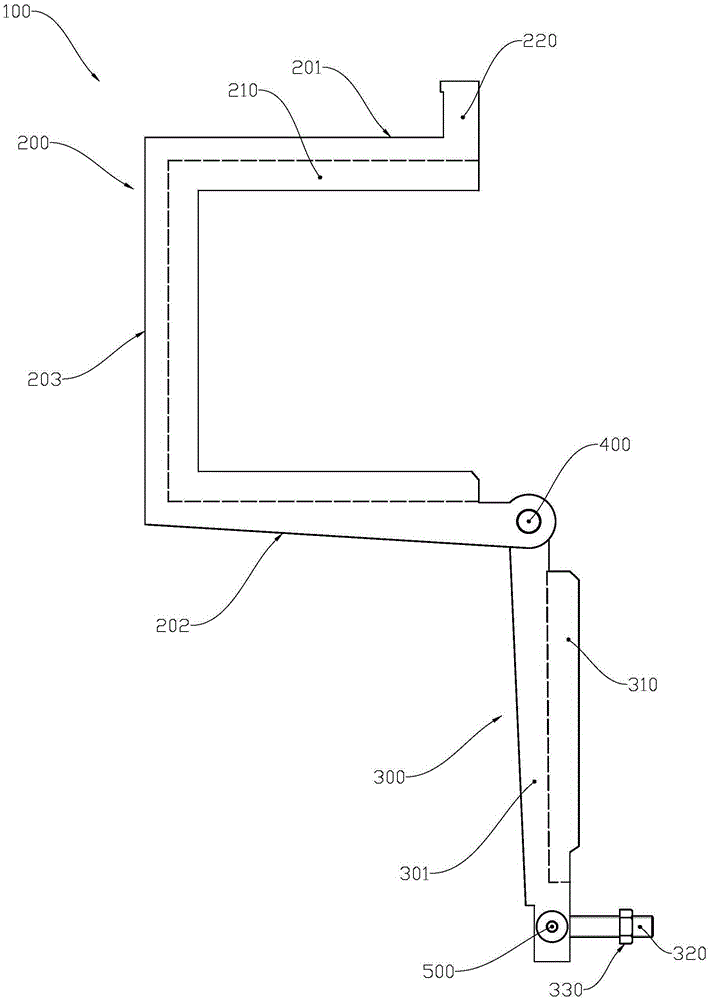

[0034] The invention is an invention and creation aimed at the jointing work of steel arch frames in tunnel construction engineering. Such as figure 1 as shown, figure 1 It is a schematic diagram of steel arch connection; the connection between the first steel arch 10 and the second steel arch 20 is through the first connecting plate 11 on the first steel arch 10 and the second connecting plate on the second steel arch 20 21, after the first connecting plate 11 communicates with the through hole on the second connecting plate 21, each high-strength bolt 30 in the four high-strength bolts 30 passes through the first connecting plate 11 and the second connecting plate 11 simultaneously. After the two connecting plates 21 are joined, a through hole is locked with a high-strength nut 31, so that the first connecting plate 11 and the second connecting plate 21 are tightly connected, thereby realizing the first steel arch 10 and the second steel arch 20 of joining.

[0035] Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com