Welding equipment structure

A technology of welding equipment and welding torch, which is applied in the field of welding equipment structure, and can solve problems such as large volume and weight, high load duration, and difficulty in moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

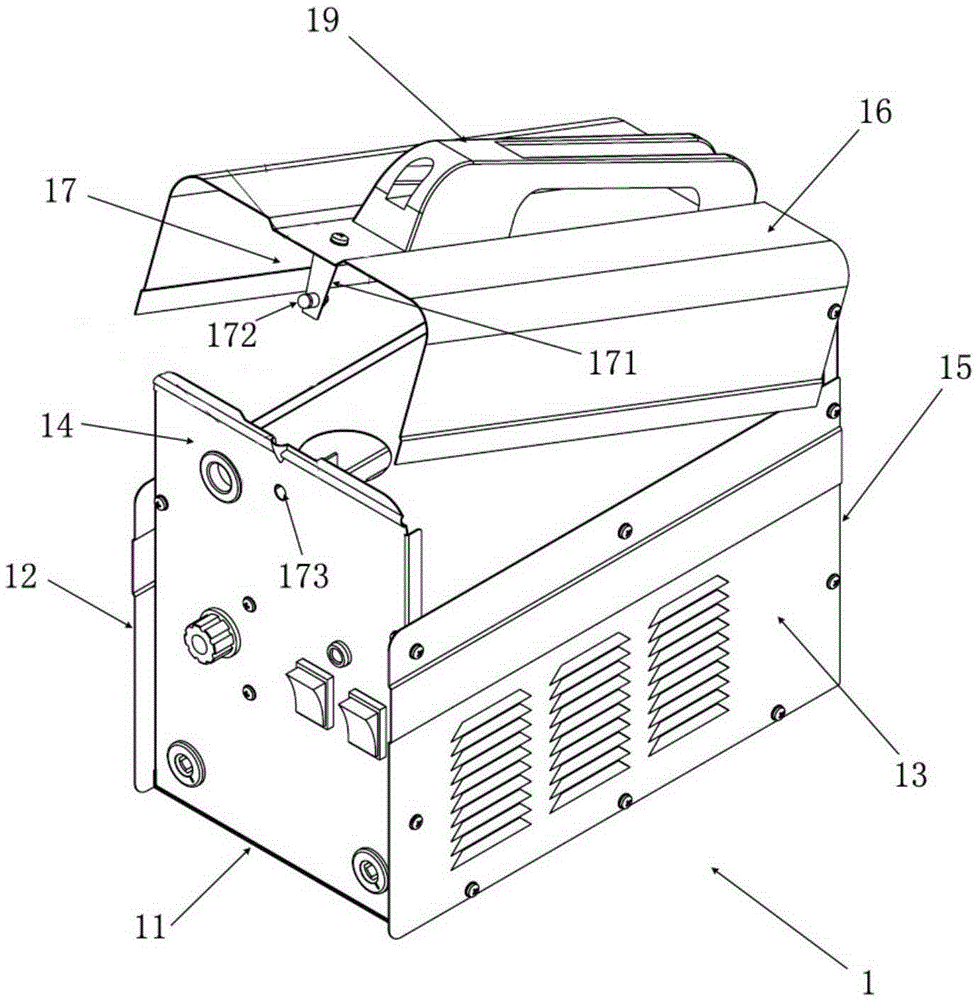

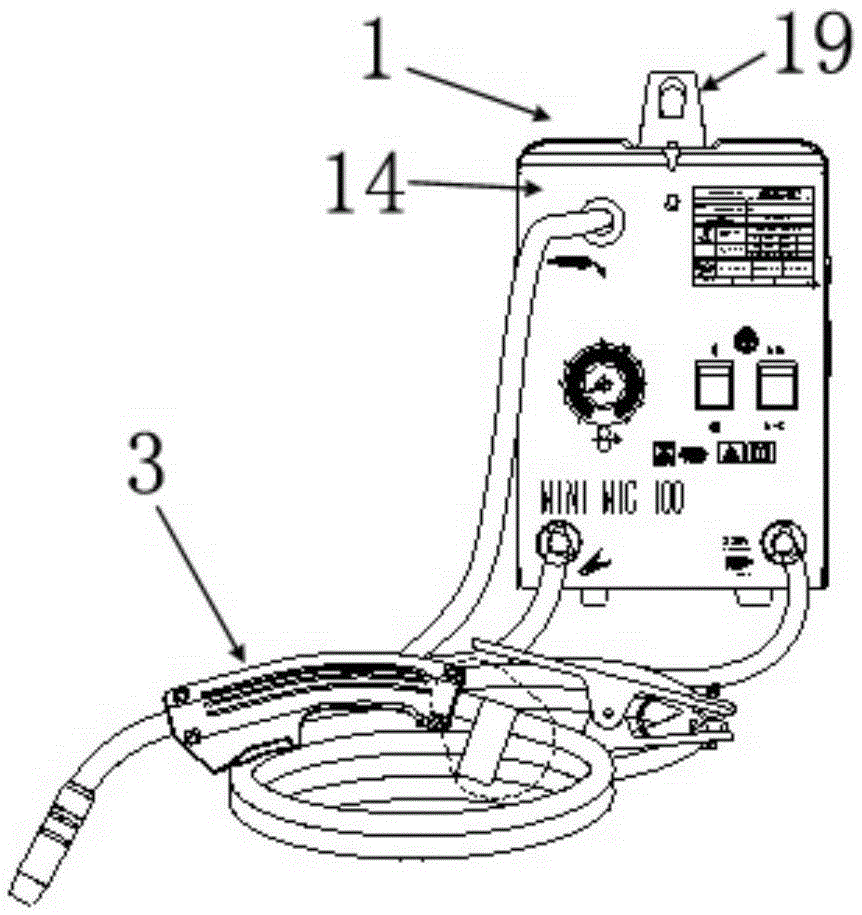

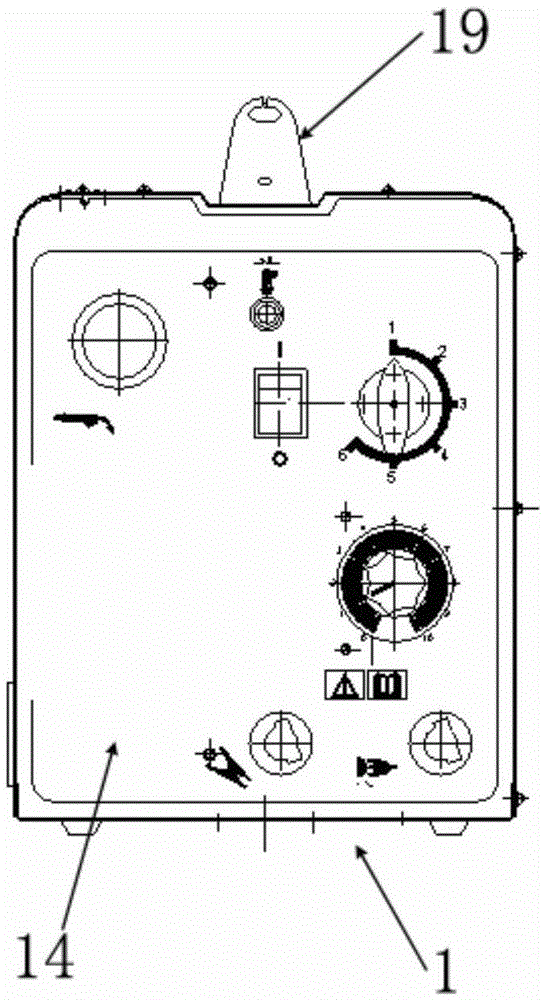

[0047] The invention discloses a welding equipment structure, including a wire feeding device 2, a welding torch 3 and a housing 1, wherein, such as figure 1 As shown, the housing 1 is a cube, including an accommodating portion composed of a bottom plate 11, a left side plate 12, a right side plate 13, a front plate 14, and a rear plate 15, and a flap plate that can be opened and closed relative to the accommodating portion. 16.

[0048] A fastening connection device 17 is disposed on the flip panel 16 adjacent to the front panel 14 . Wherein, the fastening connection device 17 includes an elastic element 171 fixed on the flip panel 16, a protruding part 172 fixed on the elastic element 171 close to the free end of the elastic element 171 and protruding outward, and a protruding part 172 arranged on the front plate 14 and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com