SiOx/Si/c composite material and process of producing thereof, and anode for lithium ion battery comprising said composite material

A technology of lithium-ion batteries and composite materials, applied in the field of composite materials, to achieve the effect of maximizing the volume buffer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Preparation of SiO x / Si composite material

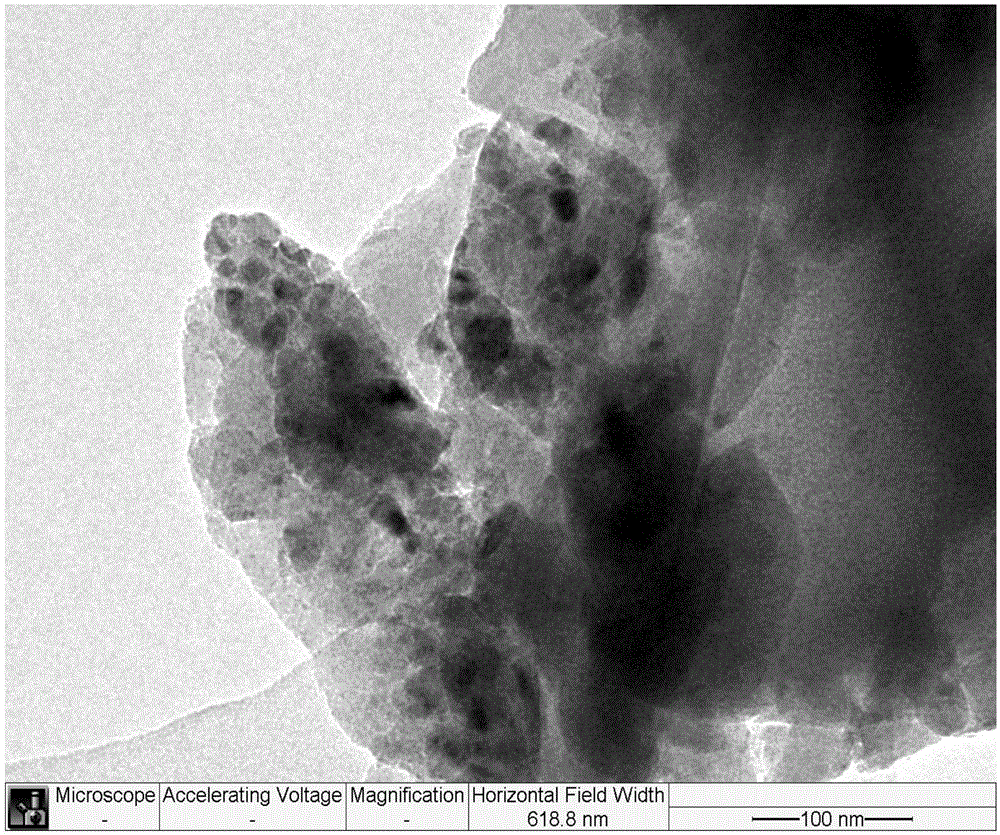

[0076] SiO was synthesized by a high energy ball milling process using PlanetaryMonoMillP-6 (Fritsch, Germany) at 400rpm for 25 hours x / Si composite material. 2.0 g of SiO (325 mesh, Aldrich) powder was charged into a 80 ml zirconia jar, and ball milled together with 10 zirconia balls (Φ=10 mm) for 10 hours. Then 0.218 g of Mg powder (200 mesh, purchased from Sinopharm Chemical Reagent Co., Ltd.) was added, and ball milling was continued for 15 hours. SiO having a D50 particle size of about 1.0 μm, a D90 particle size of about 11.0 μm, and a D10 particle size of about 0.4 μm was thus obtained. x / Si / C composite materials (such as Figure 4 shown). The resulting powder (SiO x / Si / MgO) were first impregnated with 2M HCl solution for 12 hours to remove MgO, then washed with deionized water, and finally dried under vacuum at 60 °C for 10 hours. The resulting SiO x The Si:O molar ratio of the Si / Si composite is abo...

Embodiment 2

[0080] Prepare SiO with the same method as used in Example 1 x / Si / C composites, with the difference that 2.0 g of SiO powder and 0.545 g of Mg powder were charged into the ball milling process. The resulting SiO x The Si:O molar ratio of the Si / Si composite is about 2:1.

Embodiment 3

[0082] SiO was prepared in the same manner as used in Example 1 x / Si / C composites, the difference is that 2.0 g of SiO powder and 0.872 g of Mg powder were charged into the ball milling process. The resulting SiO x The Si:O molar ratio of the Si / Si composite is about 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com