Axle body and chassis unit

A shaft body and shaft tube technology, applied in the field of shaft body and chassis unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

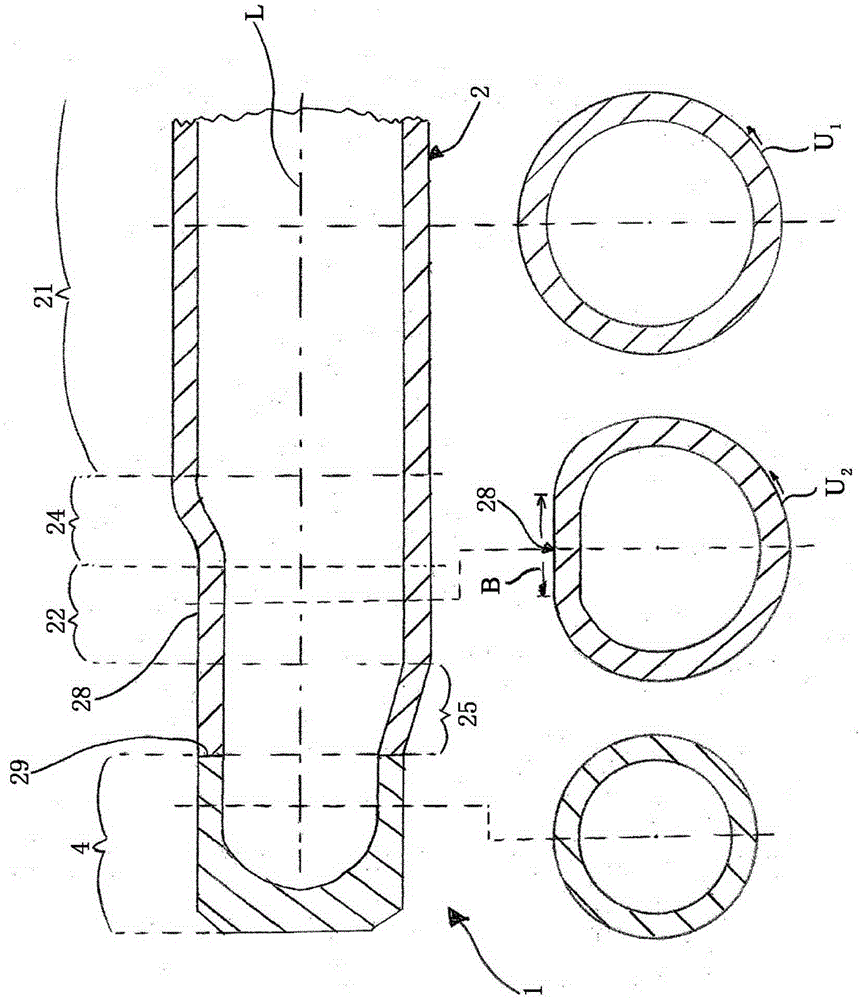

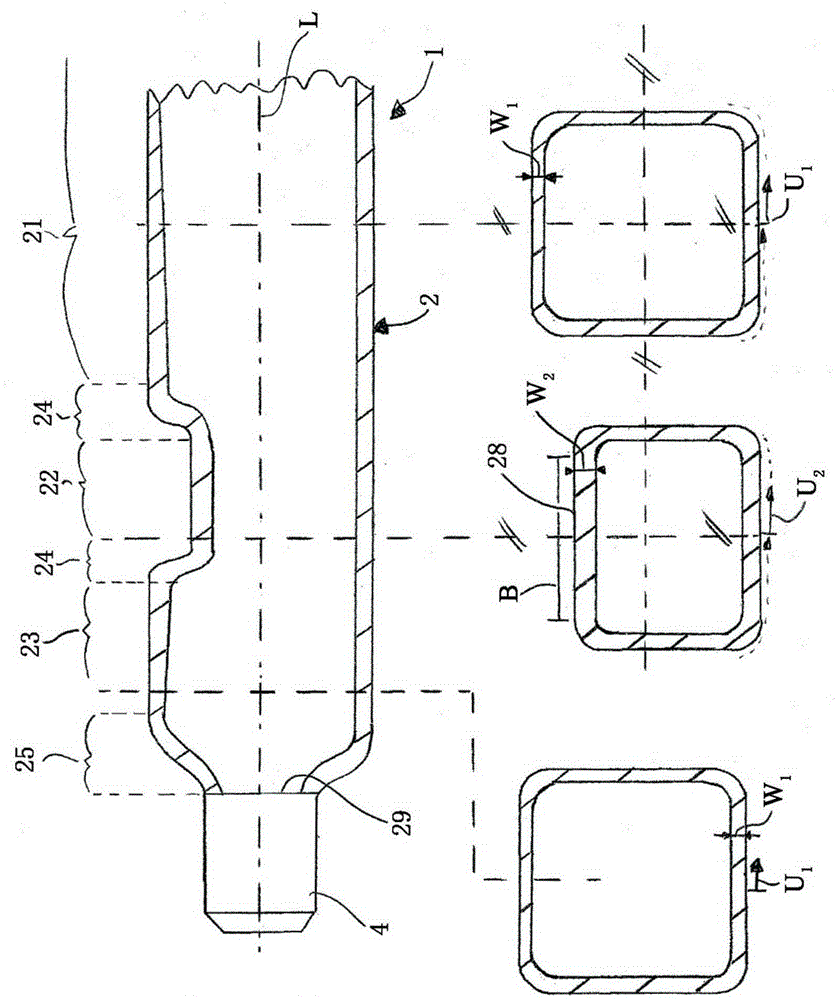

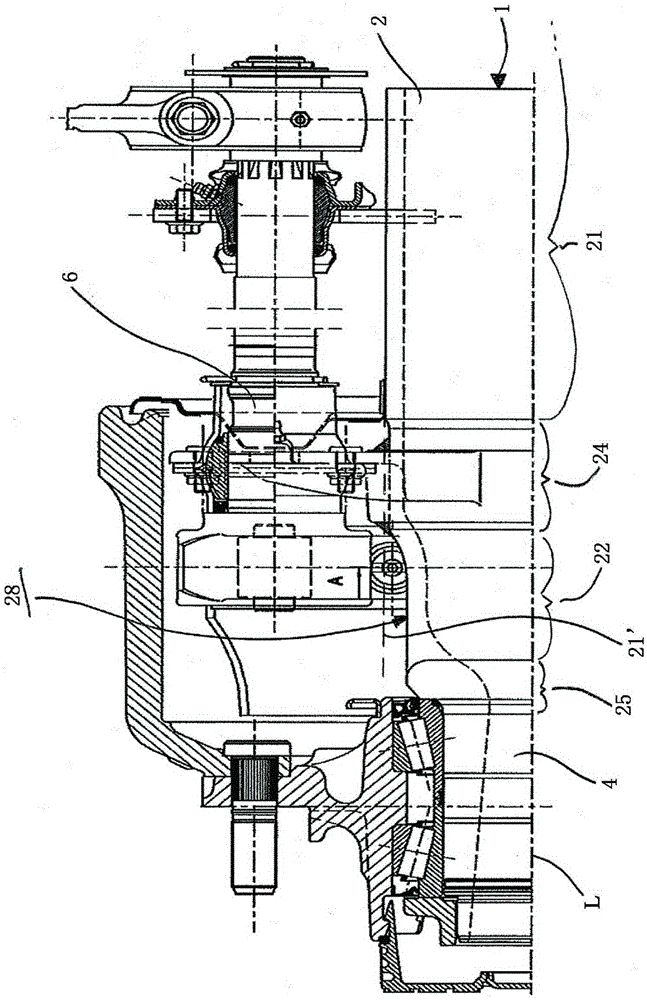

[0028] figure 1It is a sectional view of a preferred embodiment of the shaft body 1 of the present invention. The shaft body 1 has a shaft tube 2 and a shaft head 4, wherein the shaft head 4 is fixed to the shaft tube 2, preferably by friction welding. The shaft tube 2 has a first portion 21 which has a maximum extension along the longitudinal axis L and is in the form of a hollow body. Here, the cross-section or the cross-sectional geometry of the first part 21 of the shaft tube 2 is substantially constant or constant over the course of the longitudinal axis L. As shown in FIG. The first portion 21 adjoins the first transition portion 24, wherein preferably the outer contour of the first portion 21 and its inner contour transition smoothly or tangentially into the multiple curved outer contour and the inner contour of the first transition portion 24, respectively, so that Notching effects which occur at sharp edges of the body under load are reduced in particular. Furtherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com