Vibration signal noise removal device

A vibration signal and noise technology, which is applied in the field of vibration signal noise removal device, can solve the problems of poor stability and low precision, and achieve the effects of strong instantaneous overload capacity, fast adjustment, and resolution of common current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

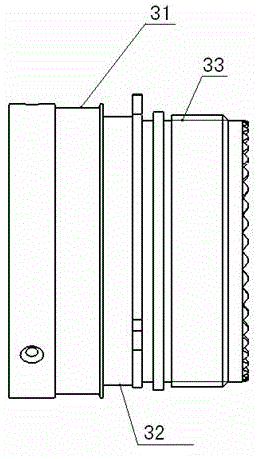

[0010] The vibration signal noise removal device described in this embodiment, see the attached figure 1 , 2, placed between the outlet of the low-voltage side of the voltage and the end user, and it is connected in parallel with the main control circuit (4); the vibration signal noise removal device is mainly composed of a transformer (1), an AC chopping unit (2), an output The filter (3) is composed of a transformer (1) connected in series at the outlet of the low-voltage side, and the transformer (1) is connected in series with an AC chopper unit (2) and an output filter (3) in sequence, and the output filter (3) is connected to an end user.

[0011] The vibration signal noise removal device of this embodiment, wherein, the compensation device is provided with a drive protection circuit (6) for driving and protecting the AC chopper unit (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com