A working sample measuring and testing method for testing couplers

A technology of measuring and testing and templates, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of working sample measurement errors, inability to measure in full size, structural size errors, etc., achieve high precision, improve inspection accuracy and efficiency, Avoid the effect of cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

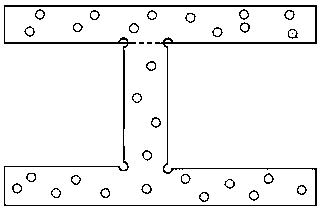

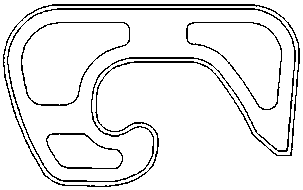

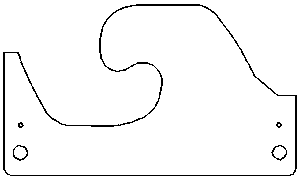

[0028] Embodiment: a kind of working model measurement and detection method for checking the coupler, comprising the following steps:

[0029] a) Paste positioning mark points on the corresponding parts of the working template for coupler parts as the reference point for scanning point cloud superposition and splicing. At least 4 mark points are required for point cloud superposition, and the total number of pasting mark points is based on the working model It depends on the size and complexity of the detected surface.

[0030] b) Using a three-dimensional scanner, according to the position to be detected on the working surface of the working model, project a grating with white light on the corresponding part of the working model, and use two cameras of the scanner to capture the distorted grating image, and the computer system processes the shooting points on the corresponding surface of the working model The three-dimensional space coordinates of the model to realize the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com