Pressing-injecting oil cylinder with pressurization system

A technology of supercharging system and oil cylinder, which is applied in the field of oil cylinder and injection cylinder, can solve the problems of complex structure, increased cost and reduced injection speed, and achieves the effect of simple structure, convenient installation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

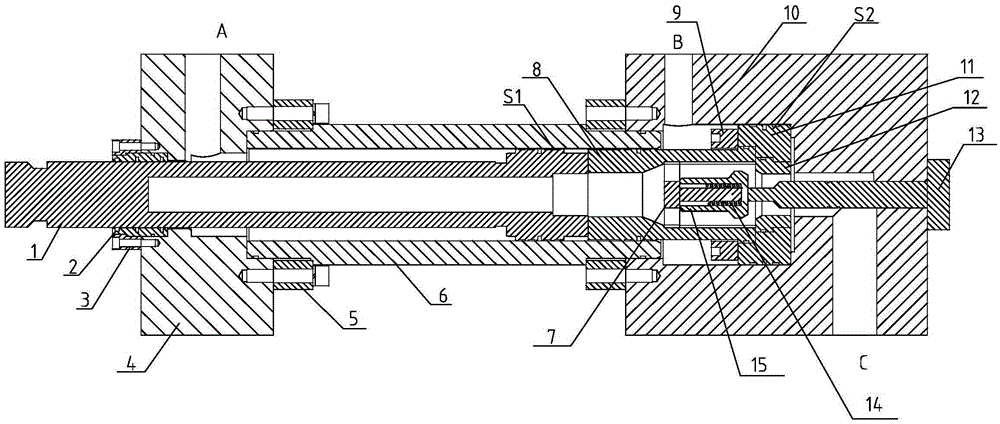

[0013] The technical scheme of the present invention will be further explained below in conjunction with the drawings:

[0014] Such as figure 1 As shown, the injection cylinder with its own booster system includes the injection piston rod 1, the cylinder barrel 6, the spring gland 7, the booster piston rod 8, the booster piston 11, the one-way valve sleeve 12, and the valve core top Rod 13, one-way valve spring 14 and one-way valve core 15, the front end of the cylinder barrel 6 is mounted with a cylinder front cover 4, the rear end is mounted with a cylinder rear cover 10, the injection piston rod 1 passes through the cylinder front cover 4 and is placed The cylinder barrel 6 of the oil cylinder can move in the axial direction. The booster piston 11 is located in the inner cavity of the back cover 10 of the cylinder. The booster piston 11 is connected and fixed with one end of the booster piston rod 8 through the booster piston rod cover 9 The other end of the pressure piston r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com