Tail-stage movable blade body structure for half-rotating-speed nuclear turbine

A steam turbine, half-speed technology, applied in the direction of machines/engines, blade support components, mechanical equipment, etc., can solve the problems that affect the vigorous development, the pace of promotion, the low efficiency of steam turbines, and the disadvantage of going abroad, so as to improve the efficiency of work and Cost-effective, enhance market competitiveness, and change the effect of reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

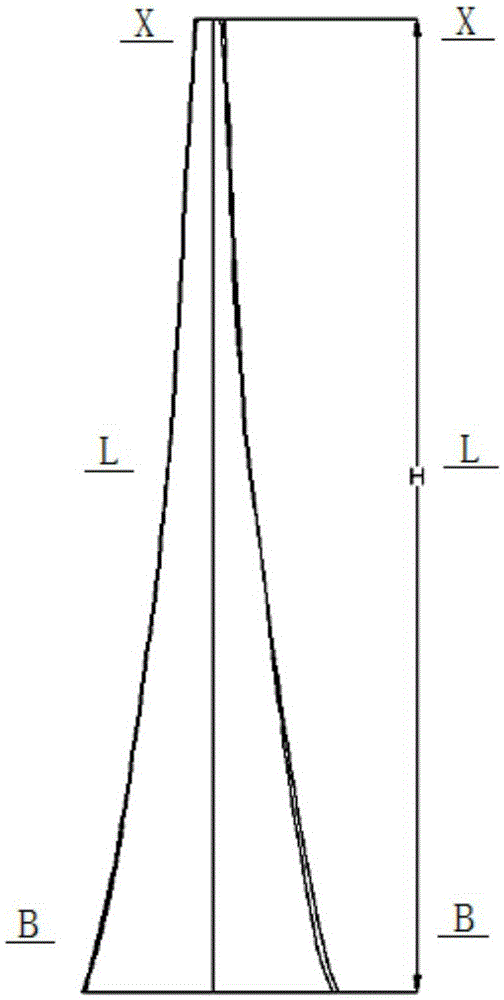

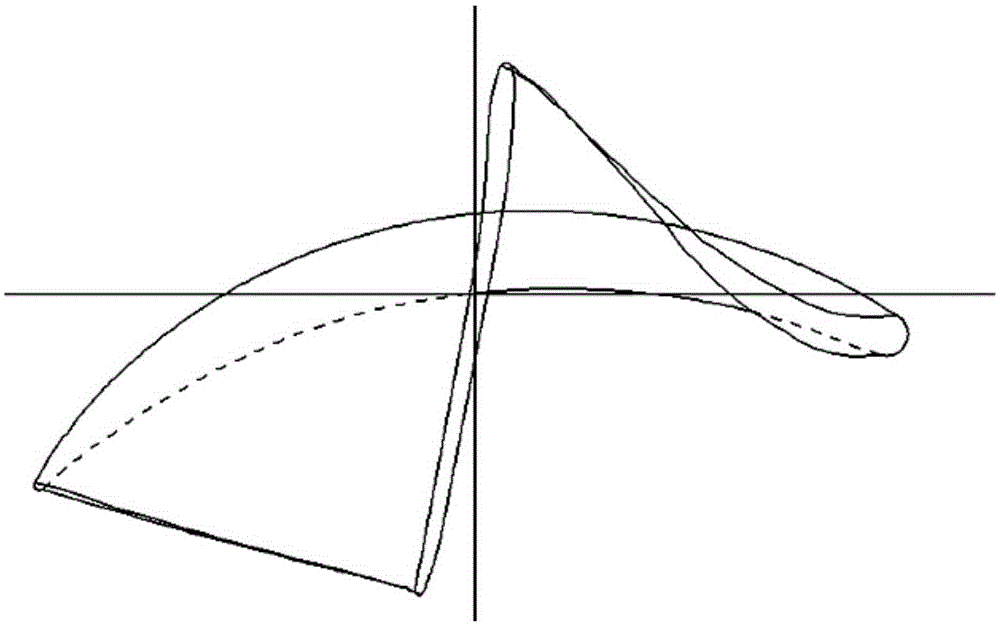

[0023] The present invention is the airfoil structure of the last-stage moving blade of a half-speed nuclear power steam turbine, and the technical problems to be solved and the technical measures to be taken are:

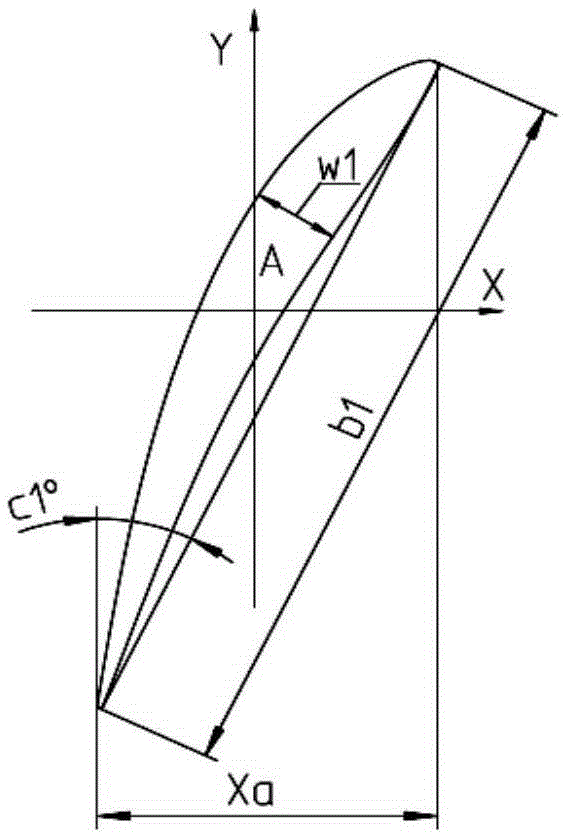

[0024] 1. Airfoil characteristic parameter design

[0025] Based on the boundary conditions required by the project, it is determined that the exhaust velocity range of this blade type is 200-250m / s, the root diameter range is 2800-3200mm, and the maximum exhaust area is 24.1m 2 , the effective blade height ≤ 1651mm, the maximum Mach number < 2.0.

[0026] The streamline curvature method is used to complete the flow matching of the low-pressure module, and the basic characteristic parameters of the blade type are determined. The geometric inlet angle ranges from 50 to 169°, and the effective geometric angle ranges from 40.4 to 10°.

[0027] 2. Blade design

[0028] The airfoil shape line of this set of blades uses the special three-dimensional modeling software f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com