Mechanized distilling utensil filling equipment

A technology of equipment and conveyors, applied in the preparation of alcoholic beverages, etc., can solve the problems of high labor intensity, low production efficiency and high production costs for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

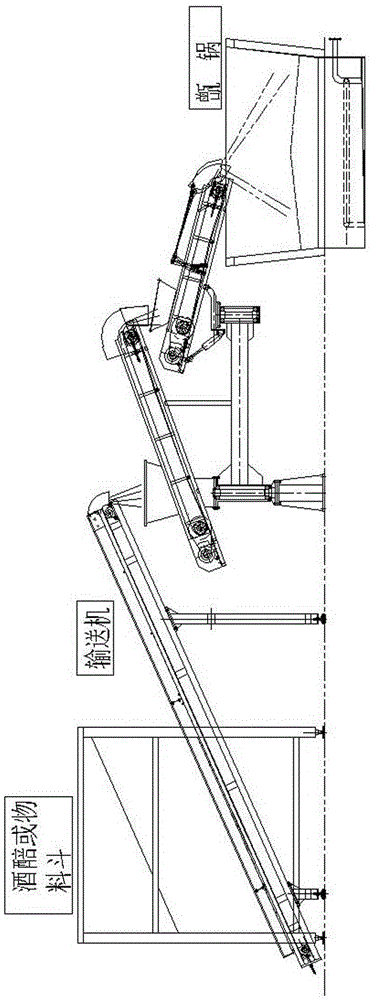

[0049] Examples such as figure 1 , figure 2 As shown, a mechanized retort equipment includes a first conveying mechanism 22 for transferring materials, a second conveying mechanism 23 for conveying and throwing materials, and the first conveying mechanism 22 is used for conveying materials to the second conveying mechanism 23. The second conveying mechanism 23 is used to evenly sprinkle the materials into the retort.

[0050] The first delivery mechanism 22 includes a first conveyor 28, the first conveyor 28 has an input end and an output end, the input end of the first conveyor 28 has a first hopper 10, and the output end of the first conveyor 28 has a shield 13.

[0051] The first conveyor 28 also includes a first motor 5, a first motor pulley 6, a first large pulley 7, a first conveying flat belt 8, a first driving roller 9, a first driven roller 12, a first The feeding flat belt 8 is supported by the first driven roller 12 and the first driving roller 9, the first moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com