Elastic clamp

A fixture and elastic technology, applied in the field of machinery, can solve problems such as complex fixture structure, unfavorable economic benefits for manufacturers, multiple fixing steps, etc., and achieve good application prospects, simple structure, and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

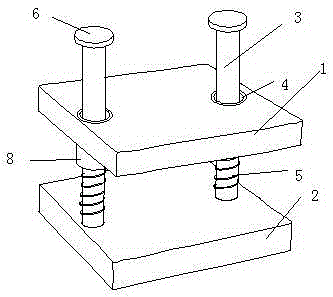

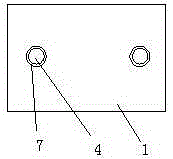

[0017] Such as figure 1 and figure 2 As shown, a kind of elastic clamp, comprises upper splint 1, lower splint 2 and the guide bar 3 that connects upper splint 1, lower splint 2 that are arranged oppositely, preferably upper splint 1, lower splint 2 are square, and its structure is simple, easy Manufactured, and the clamping stability is high, and the guide rod 3 is perpendicular to the upper splint 1 and the lower splint 2 to ensure the direction of the guiding clamping force. The upper splint 1 is provided with a socket 4, and the lower end of the guide rod 3 Through the socket 4 and fixed on the lower splint 2, a spring 5 is sleeved on the guide rod 3 between the upper splint 1 and the lower splint 2, preferably the guide rod 3 is set as two, symmetrically arranged on both sides of the splint , and the guide rod 3 is a cylinder, the cylinder is more in line with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com