Coulter type mixing machine

A mixer and coulter-type technology, applied to mixers, mixers with rotating stirring devices, dissolving, etc., can solve problems such as poor mixing effects, and achieve reliable operation, high mixing precision, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

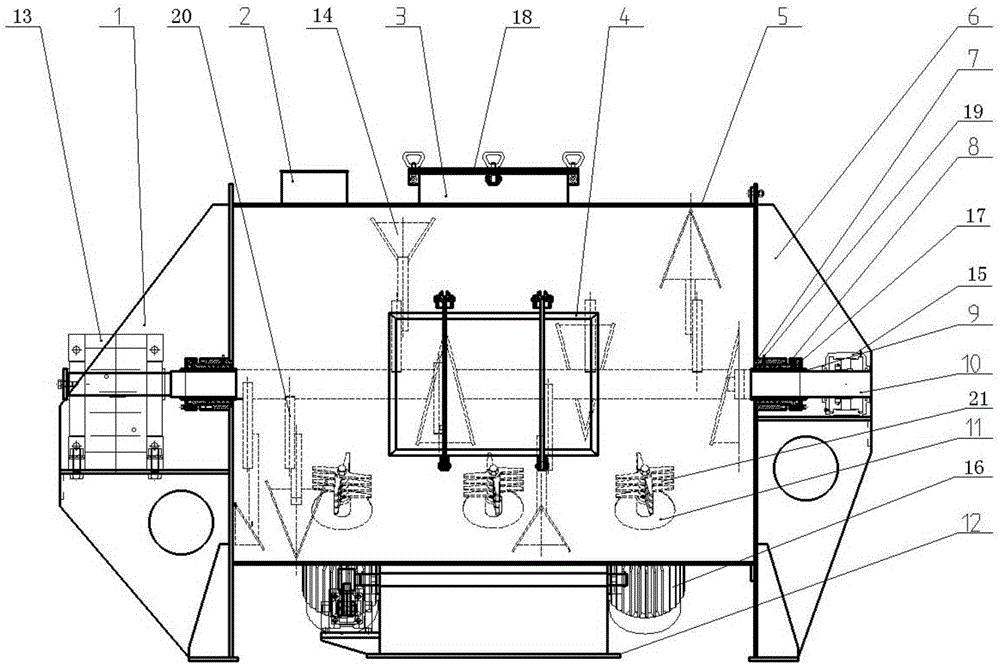

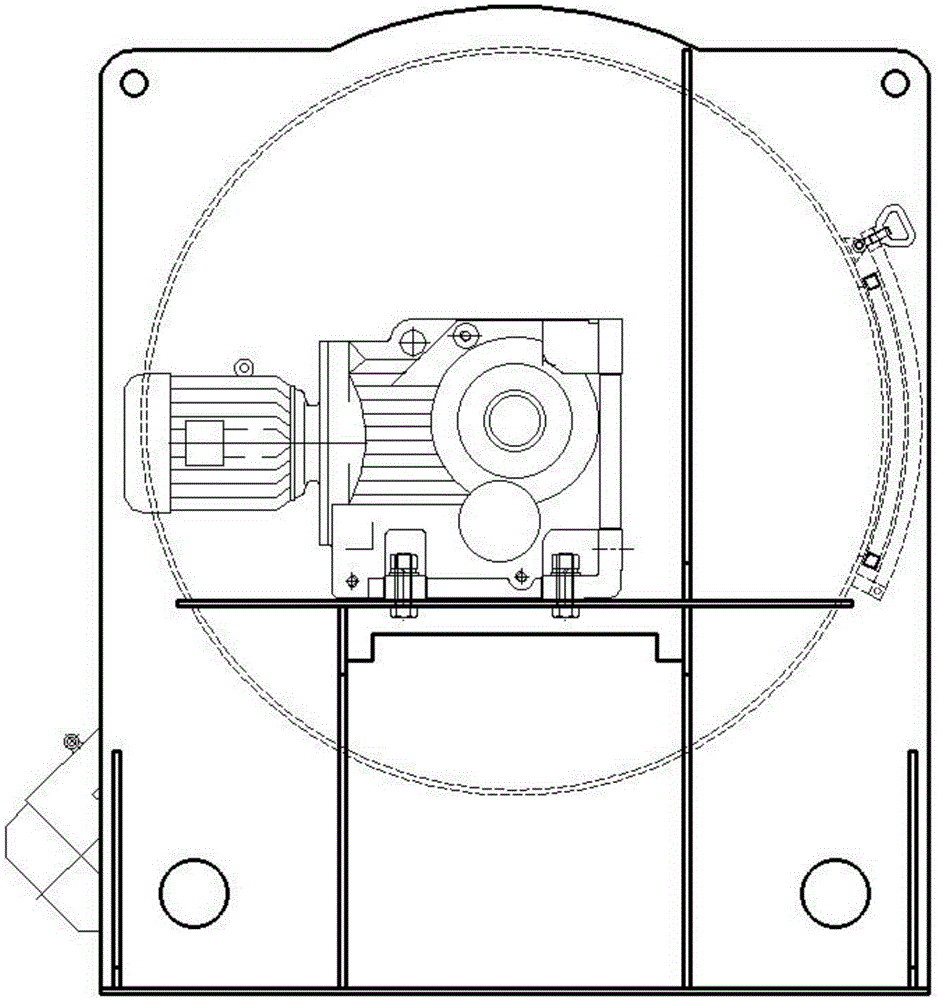

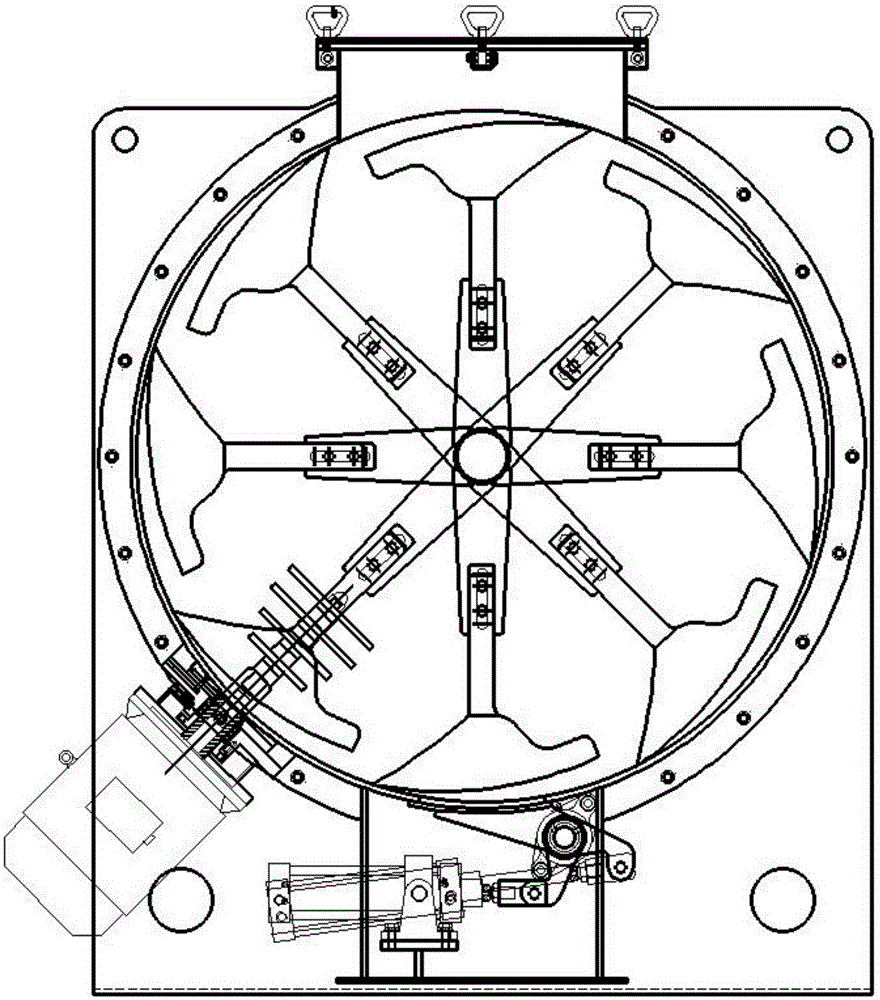

[0028] Such as Figure 1-3 As shown, a coulter 14 type mixer includes a cylindrical barrel 5, a reduction motor 13, a main shaft 10, a set of coulters 14 and three sets of flying knife devices 11. The left end of the cylinder body 5 is connected with the left wall panel 1, the right end is connected with the right wall panel 6, and the bottom of the left and right wall panels 6 are provided with support seats and support reinforcement ribs. A feed port 2 is provided on the top of the cylinder 5, and a manhole 3 is provided on one side of the feed port 2. The manhole 3 is equipped with a top cover 18 in a quick-opening manner, and the cylinder 5 is also provided The arc-shaped inspection door 4 is hinged with a closed door panel at the bottom of the arc-shaped inspection door 4, and two quick-locking fixtures are arranged on the outside of the closed door panel, and the top of the arc-shaped inspection door 4 is equipped with a quick-locking fixture to match The lock used. A di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com