Method for calculating total ship steam consumption

A technology of steam volume and steam, applied in the field of ships, can solve problems such as low efficiency, time-consuming, and no effective calculation software, etc., and achieve the effect of reliable basis and guarantee, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

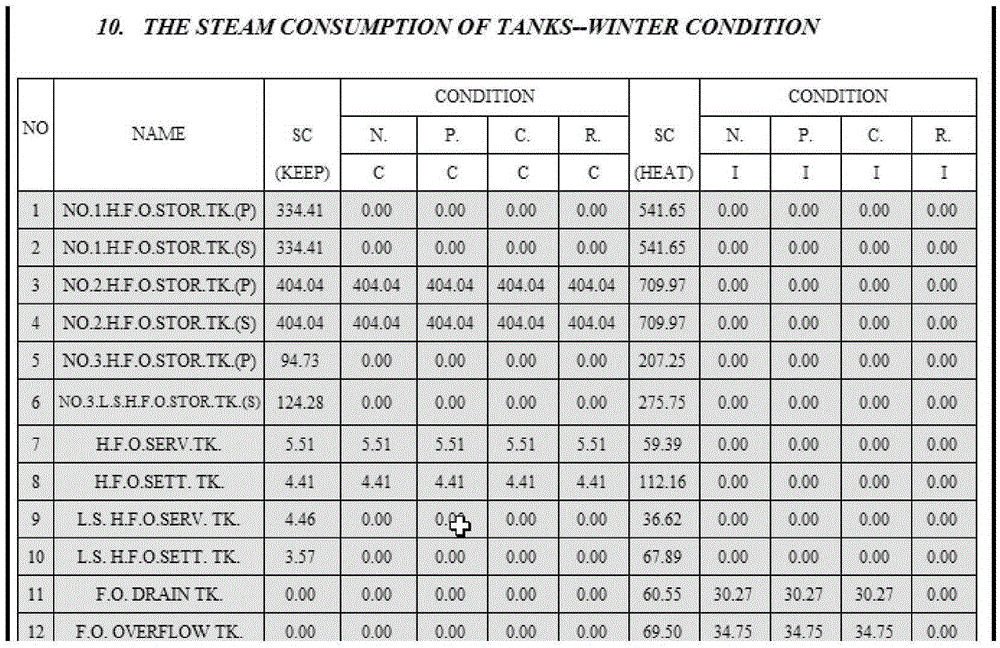

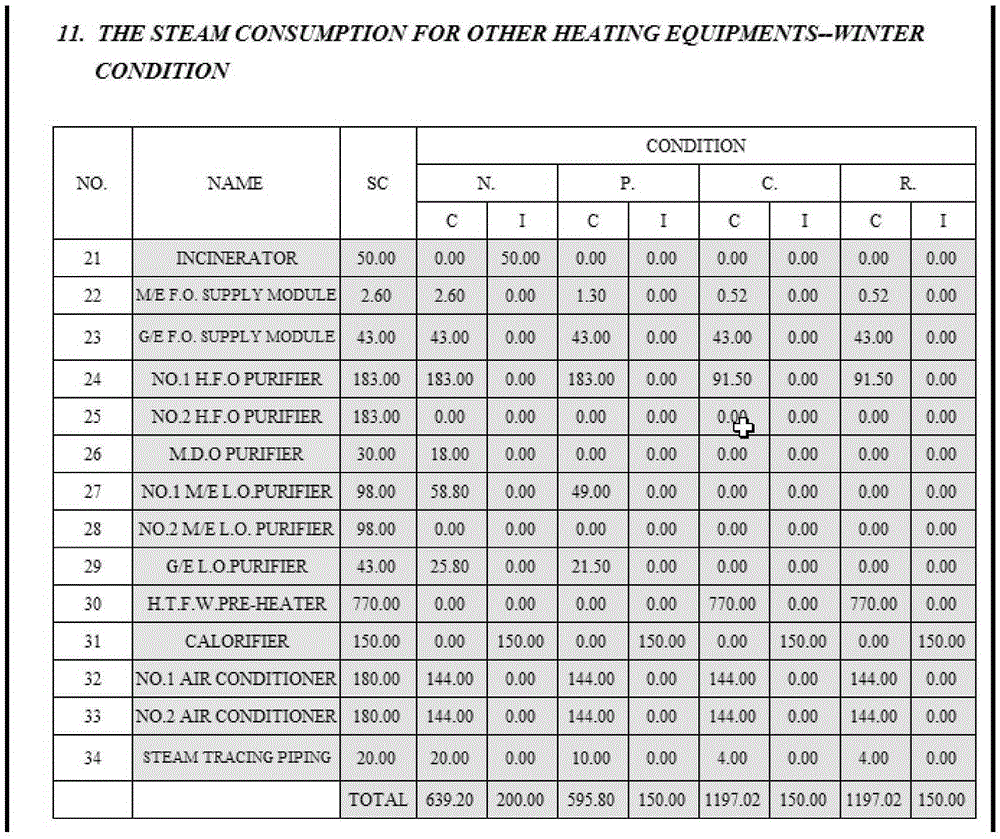

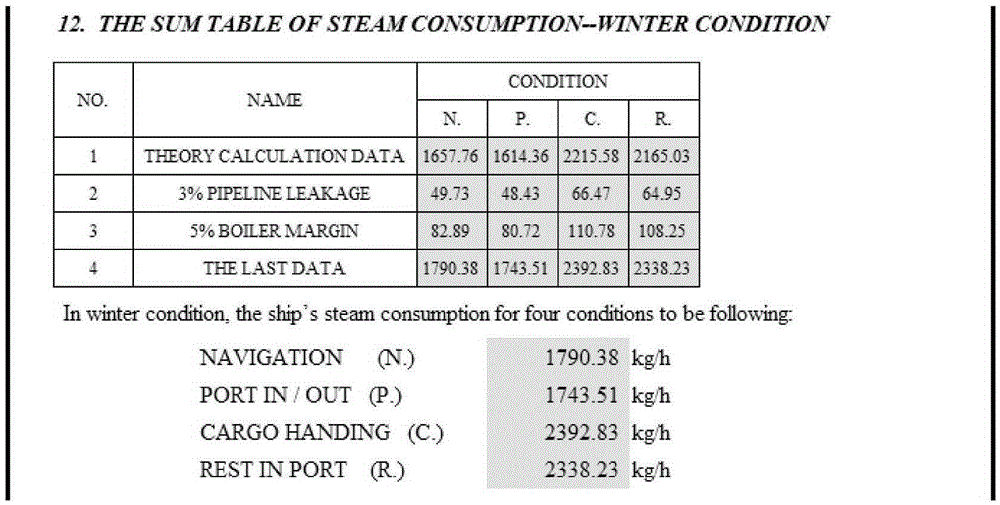

[0031] In the process of ship design, the steam consumption of equipment and ship tanks is usually estimated under various working conditions, and then the results are used as an important basis for the selection of combined boilers. Generally, the ship tank has two states, that is, the heat preservation state and the heating state, and it is assumed that the tank is a uniform body, and the heat emitted to the external medium is considered to be proportional to the temperature difference. Therefore, the steam consumption does not change under a certain constant load.

[0032] Therefore, the specific steps for calculating the total steam consumption of the whole ship are as follows:

[0033] Step 1: When the ship tank is in the heat preservation state, the heat dissipation is equal to the heating amount, and the establishment formula 1:

[0034] Σ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com