Method for forming concave-convex structure on substrate and method for making mold

A concave-convex structure and substrate technology, which can be applied to home appliances, other home appliances, instruments, etc., can solve problems such as luminance fading and easily affecting display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] This description is of the best mode currently contemplated for carrying out the invention. The invention is described herein with reference to various embodiments and drawings. This description has been produced to illustrate the general principles of the invention and should not be executed in a limiting sense. Those skilled in the art will understand that changes and improvements can be made by virtue of these teachings without departing from the scope and spirit of the invention. The scope of the invention is best understood with reference to the scope of the claims.

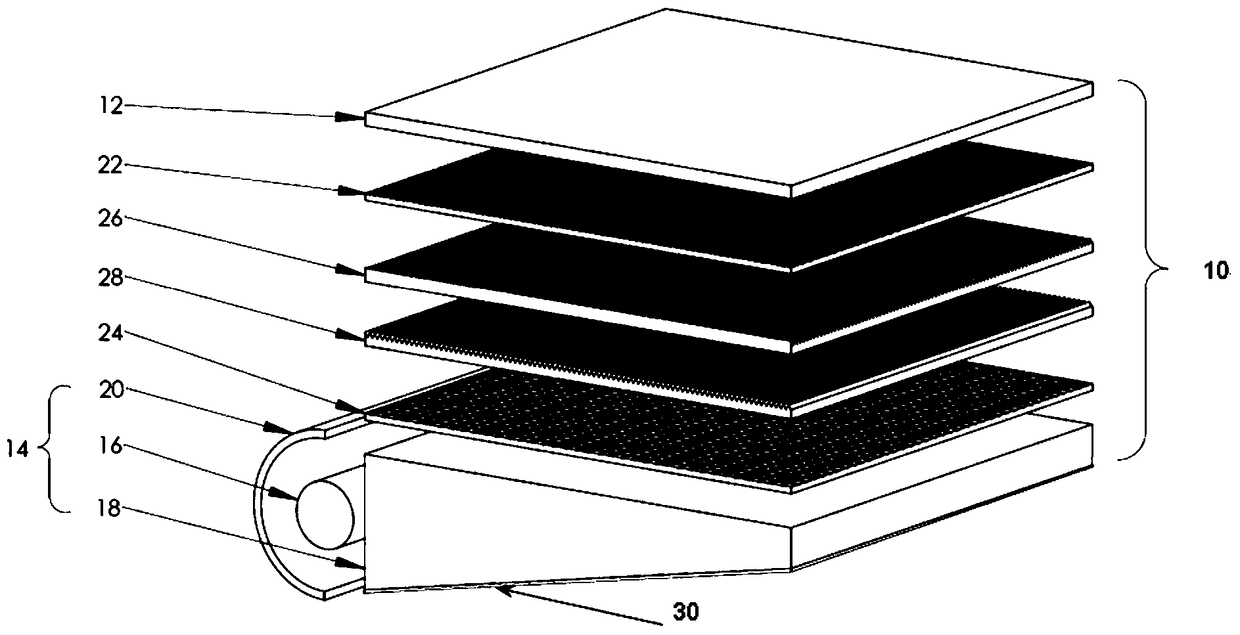

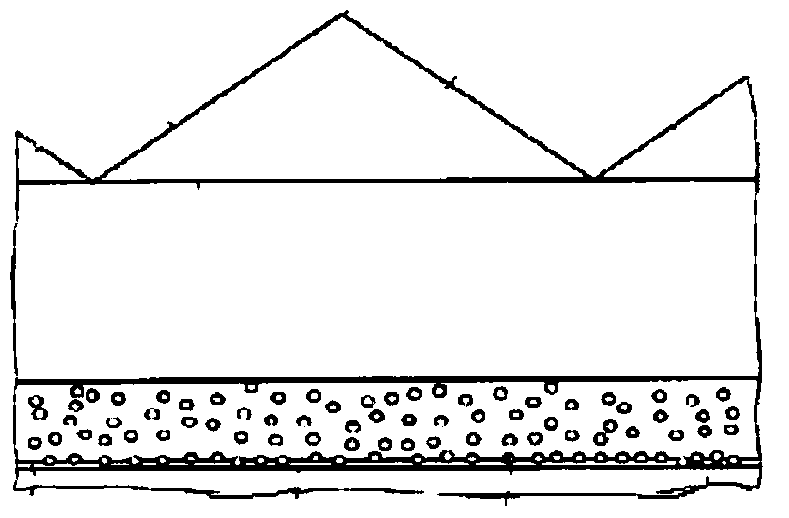

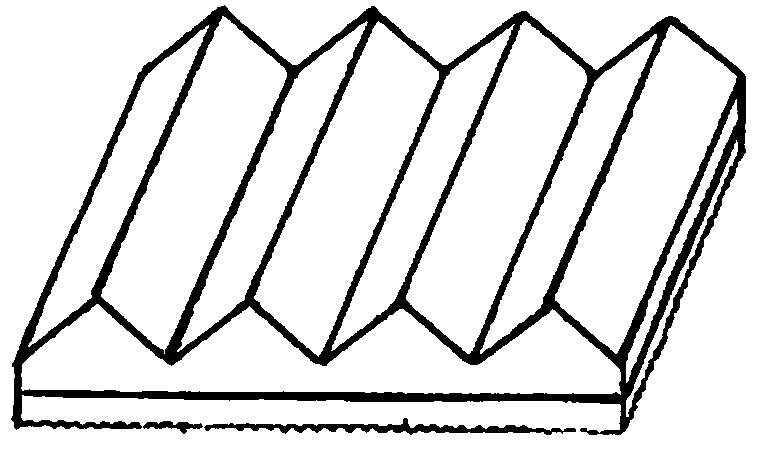

[0070] The invention relates to a diffusion prism substrate with functions of light collimation and light diffusion. More particularly, the present invention is directed to optical substrates having structured surfaces that enhance brightness or brightness by collimating light and enhancing light diffusion. In one aspect of the invention, the optical substrate is in the form of an optical substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| gain coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com