Anti-lightning-stroke performance testing system and method of horizontal-shaft wind turbine blade

A technology for wind turbine blades and testing systems, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem of low cost, achieve low cost, simple test facilities, and meet the needs of research and development and testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

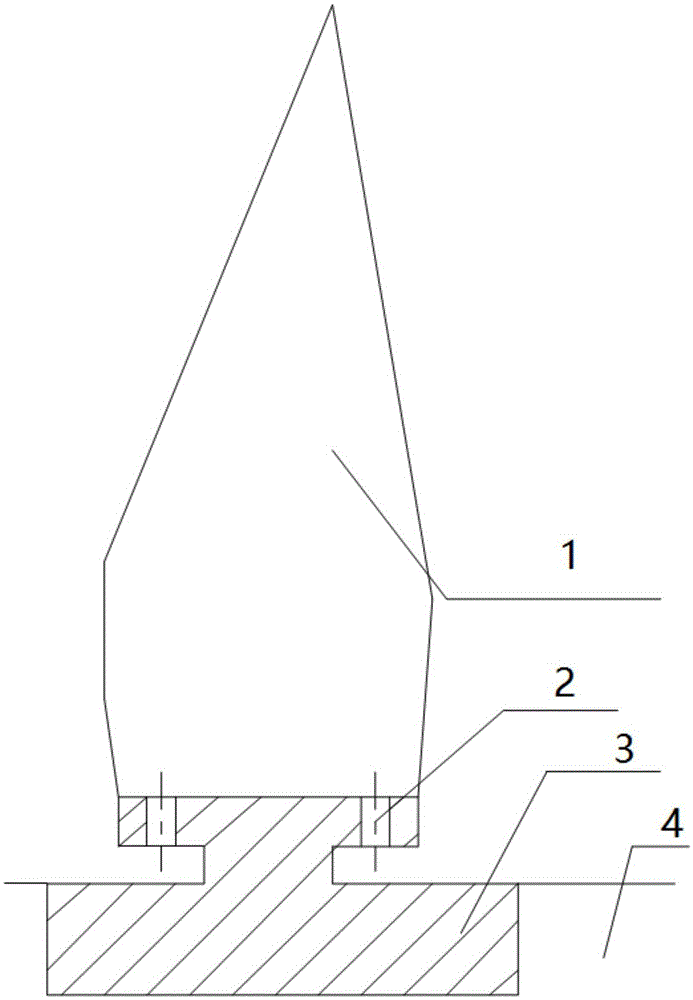

[0036] like figure 1 , 2 Shown, in implementing the anti-lightning strike performance testing method of the present invention, need to use such as figure 1 The blade fixing platform 3 shown is set on the ground 4 in the field environment where lightning is prone to occur. When in use, the blade 1 to be tested and evaluated is placed on the fixing platform 3, and the blade 1 and the The fixed platform 3 is fixed so that the tip of the blade 1 is upright and stands on the fixed platform 3 .

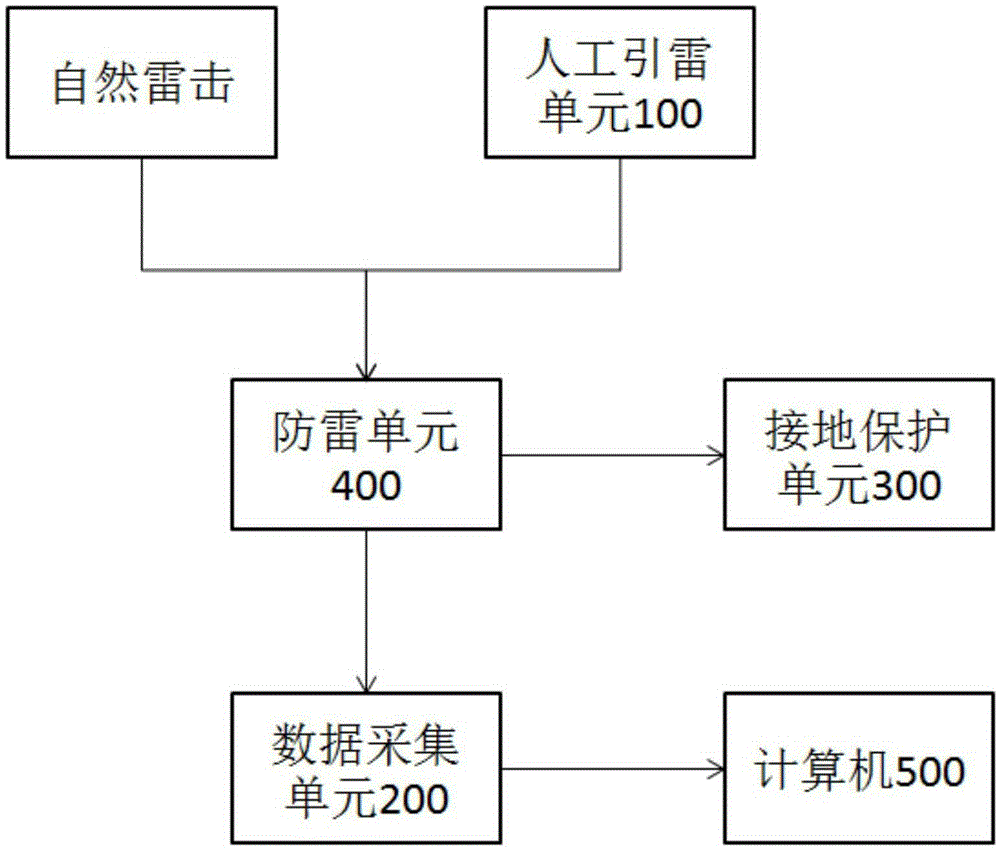

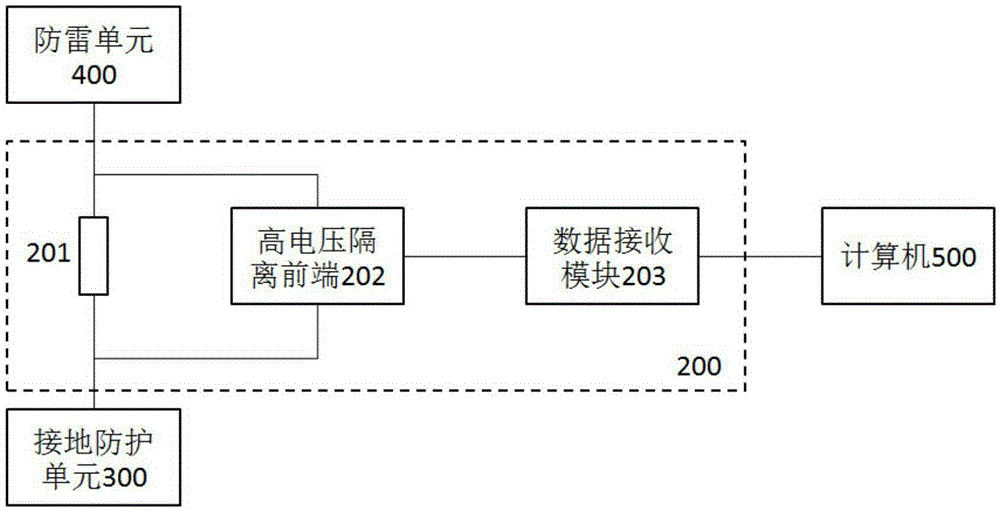

[0037] like figure 2 As shown, the blade lightning resistance performance testing system of the present invention includes an artificial lightning induction unit 100 arranged outside the blade, a data acquisition unit 200 , a grounding protection uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com