Ultrasonic liquid level sensing system

一种超声传感器、液位的技术,应用在液面指示器、液体/流体固体测量、仪器等方向,能够解决不能准确地测量化学试剂、传感器限制等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

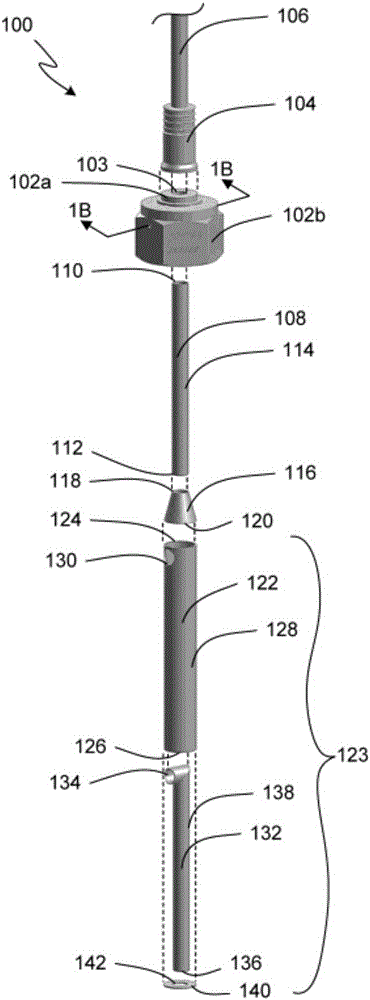

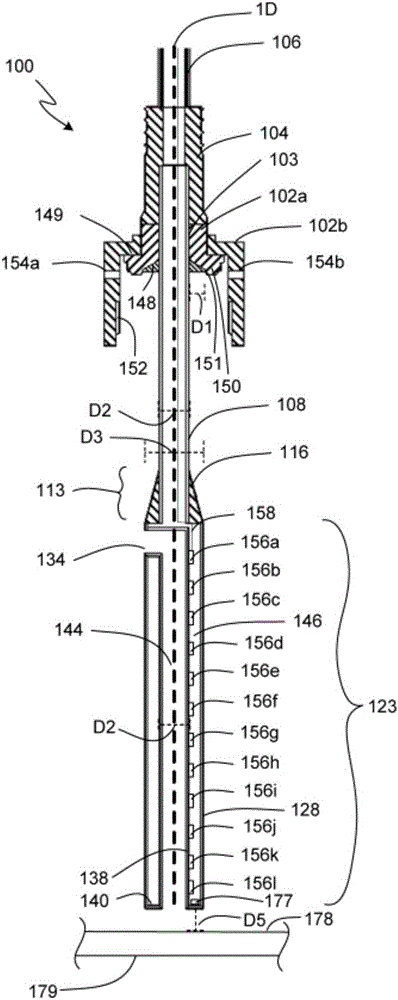

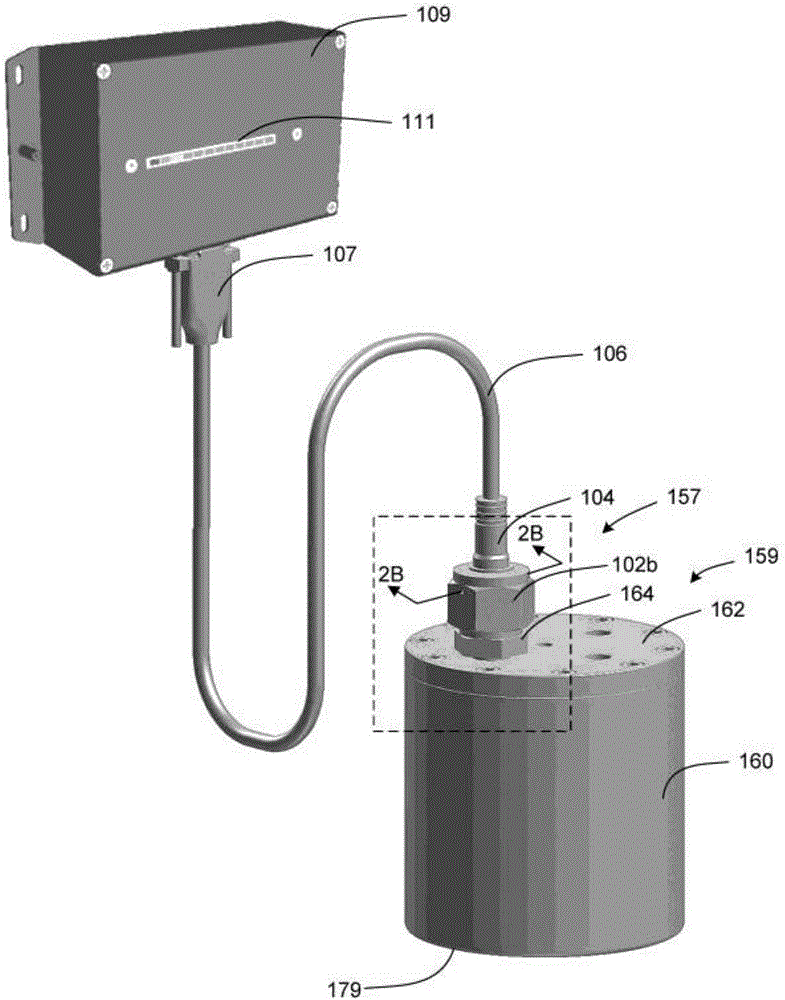

[0043] The following detailed description provides preferred exemplary embodiments only, and is not intended to limit the scope, applicability, or configuration of the invention. Rather, the detailed description of the preferred exemplary embodiment that follows provides descriptions to enable those skilled in the art to practice the preferred exemplary embodiment of the invention. Various changes may be made in the function and arrangement of elements without departing from the spirit and scope of the invention as set forth in the appended claims.

[0044] In the figures, elements similar to those of other embodiments of the invention are indicated by increasing the value of reference numerals by 100. Such elements should be considered to have the same function and characteristics unless otherwise stated or described herein, and thus discussion of such elements may not be repeated for multiple embodiments.

[0045] The term "conduit" as used in the specification and claims r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com