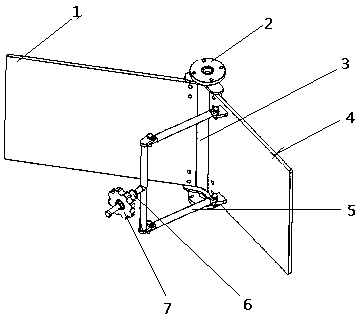

a wind guide mechanism

A technology of air guiding mechanism and connecting rod mechanism, which is applied in mechanical equipment, space heating and ventilation details, household heating, etc., can solve problems such as loss, prolong product development cycle, long development cycle, etc., and meet the requirement of ensuring air volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0018] In the air path with centralized air supply and multi-channel split flow, the air supply outlet and each branch branch are usually distributed asymmetrically. In order to prevent the wind from mainly flowing away from the branch near the air inlet, it is necessary to distribute each Air volume on branch road. At the same time, due to different air supply requirements, the specifications of the air outlets are different, but the air volume requirements of the same specifications are the same. Therefore, an air guide mechanism is provided at the air inlet inside the air duct to achieve a balanced distribution of air volume.

[0019] The air guiding mechanism of the present invention comprises a rotating shaft, a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com