Torsional Vibration Assisted Rock Breaking Tool

A technology of torsional vibration and rock breaking, applied in vibration drilling, vibration generating devices, wellbore/well components, etc., can solve the problems of easy damage of drill bit cutting teeth, piezoelectric materials are not suitable for common use with conventional downhole tools, etc., to achieve The effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

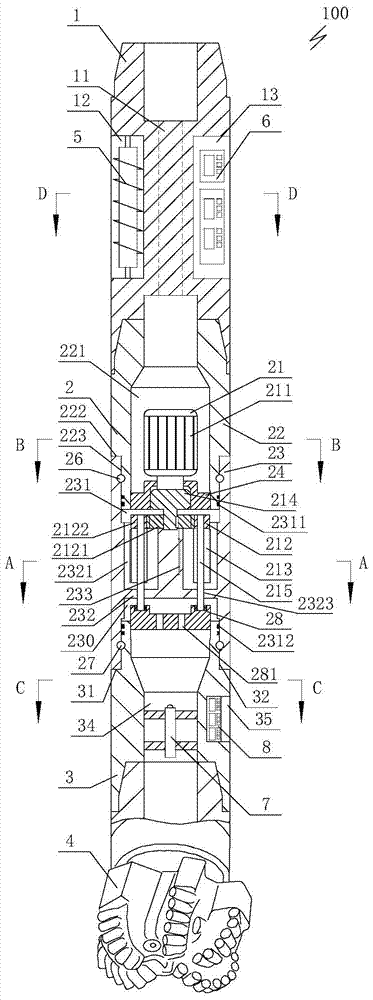

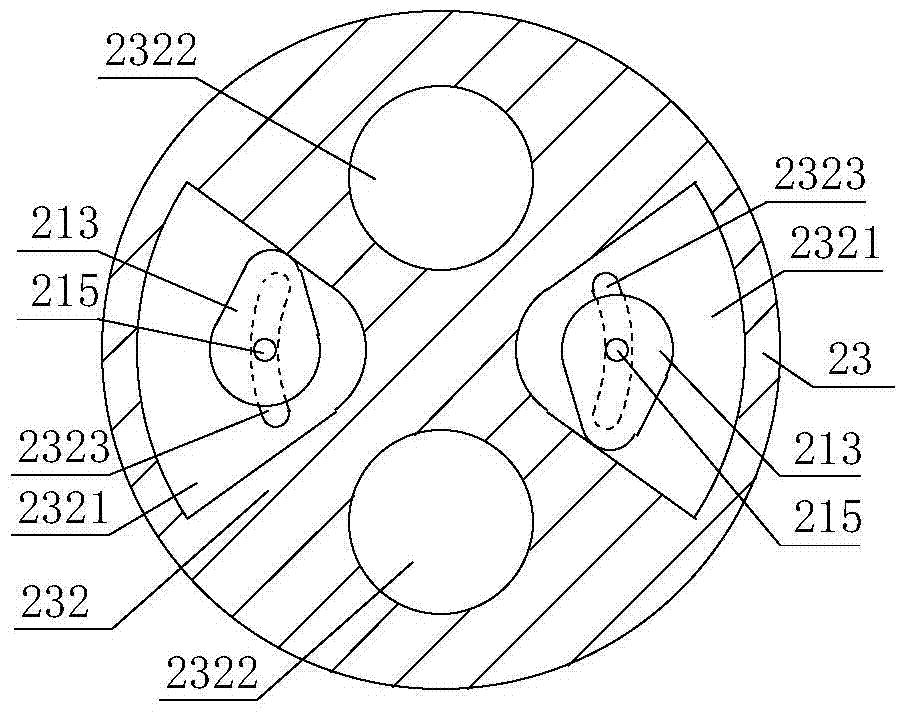

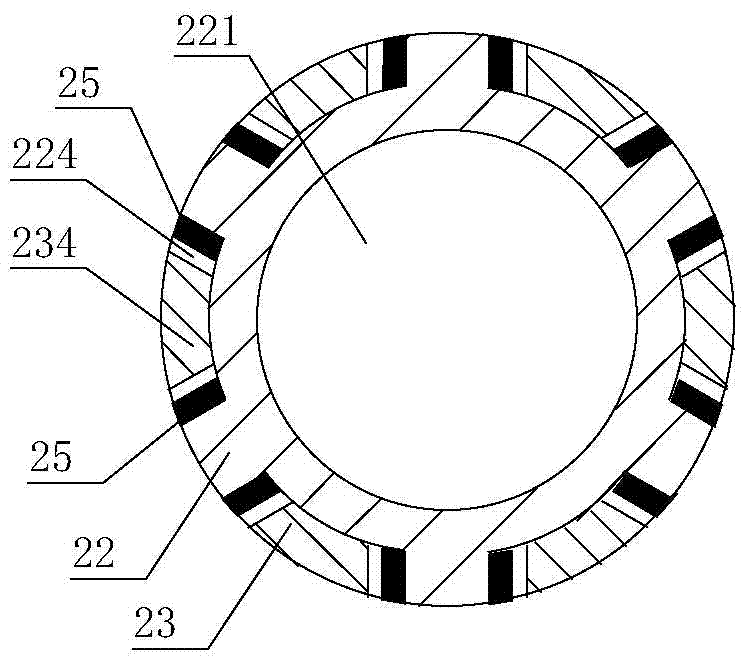

[0035] Such as figure 1 As shown, in the torsional vibration auxiliary rock breaking tool 100 provided by the present invention, a drill bit 4 is connected to the bottom of the torsional vibration auxiliary rock breaking tool 100. The torsional vibration auxiliary rock breaking tool 100 includes a measurement and control sub 1 which is connected below the measurement and control sub 1 There is a vibrating nub 2 capable of torsional vibration, a vibrating device 21 is arranged inside the vibrating nub 2, an acceleration measuring sub 3 is connected below the vibrating sub 2 and the bottom of the acceleration measuring sub 3 is connected to the drill bit 4. Under the action of the vibrating device 21, the vibrating sub 2 micro-amplitude high-freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com