Dual Frequency Axial Impact Tool

A technology of axial impact and tools, which is applied in earthwork drilling, driving devices for drilling in boreholes, and drilling equipment. It can solve problems such as short life of drilling tools, high drilling costs, and impact on the overall benefits of oil drilling and development. The effect of increasing the service life and improving the rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

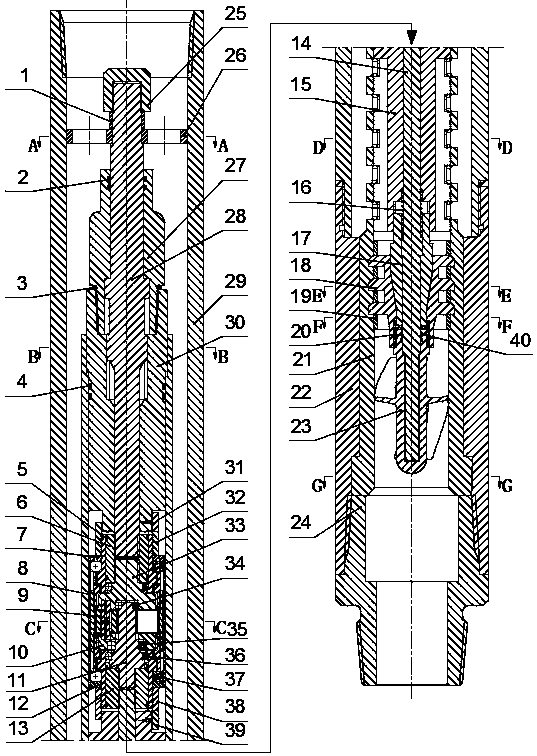

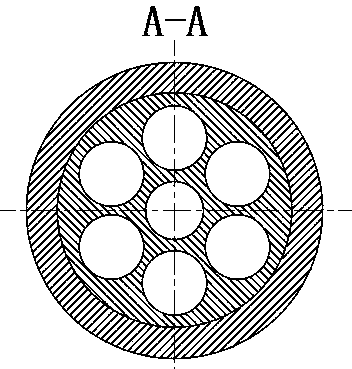

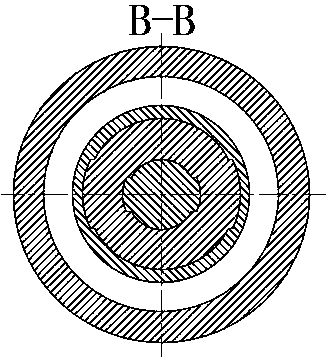

[0023] See attached figure 1 , the dual-frequency axial impact tool includes an outer shell, an impact assembly, a reducer, and a diversion assembly. The impact assembly, the reducer, and the diversion assembly are sequentially arranged in the outer shell from back to front, and the impact assembly, deceleration The device and the deflector assembly are assembled into an internal whole, and the internal whole is packed into the outer shell; the outer shell includes an upper shell 29, a lower shell 22, an outer guide tube 21, a lower joint 24, an upper shell 29 and The lower casing 22 is connected by thread, and then the outer guide tube 21 is loaded from the front port of the lower casing 22, and the circumferential positioning is realized through the keyway of the lower port of the lower casing 22, and finally the lower casing 22 and the lower joint 24 Through screw conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com