Preparation method of 3D printed optical-fiber preformed rod with cross sectional structure in optional geometrical shapes

A technology of optical fiber preform and geometric shape, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult preparation, difficult to design and prepare optical fibers with special structure and performance, and achieve low price and cross-sectional shape selectivity Easy, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

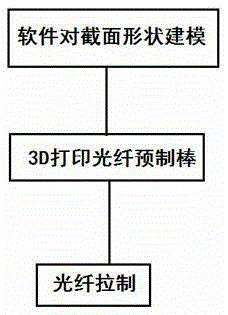

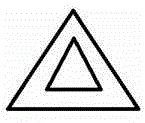

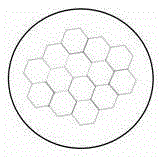

[0014] see figure 1 , the 3D printing method for preparing an optical fiber preform with any cross-sectional structure shape, the operation steps are: 1) Design various cross-sectional geometric shape models required by using 3D printing software, 2) Then use the 3D printing device according to the designed The software model prints out the optical fiber preform model of the required cross-sectional structure geometry, and can print out the optical fiber preform of any shape with various required cross-sectional structures according to the software design, 3) and then draw out various optical fiber preforms. Optical fiber with transmission and conversion characteristics-photonic crystal fiber, or eccentric fiber, or multi-core fiber, or arbitrary polygonal fiber, or its intersecting optical fiber, with various unique optical transmission and conversion properties, will provide optical fiber communication and optical sensing Provide various functional optical fibers with specif...

Embodiment 2

[0017] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0018] By using 3D printing software to design an eccentric fiber pattern with a porous cross-sectional structure geometry, and then print the cross-sectional structure as an eccentric optical fiber preform model through a 3D printing device, and then can be drawn with various light transmission and conversion characteristics. Eccentric optical fiber, to produce functional optical fiber with specific performance. Prepare and print an optical fiber preform with eccentricity, and then draw an optical fiber with eccentricity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com