Rail welding method

A welding method and rail technology, applied in the direction of rails, welding equipment, welding/welding/cutting items, etc., can solve the problems of not realizing the welding of different steel types of rails, and achieve the effect of improving the use level and the overall level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

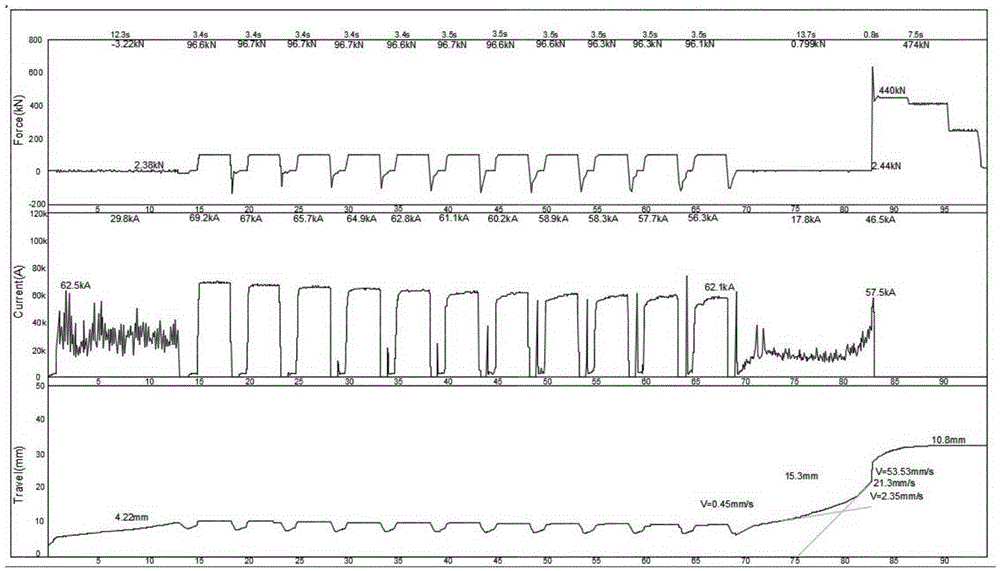

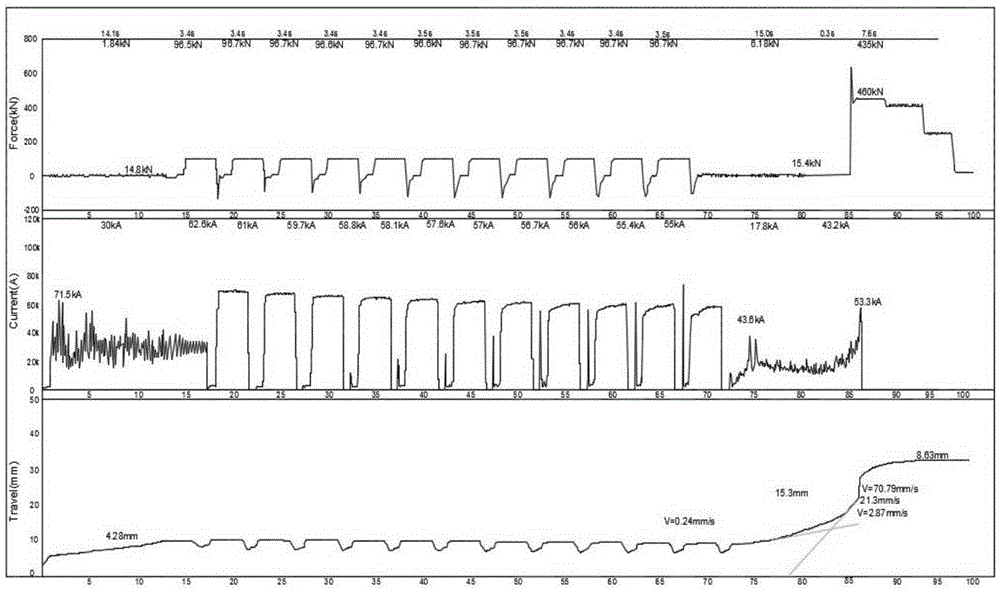

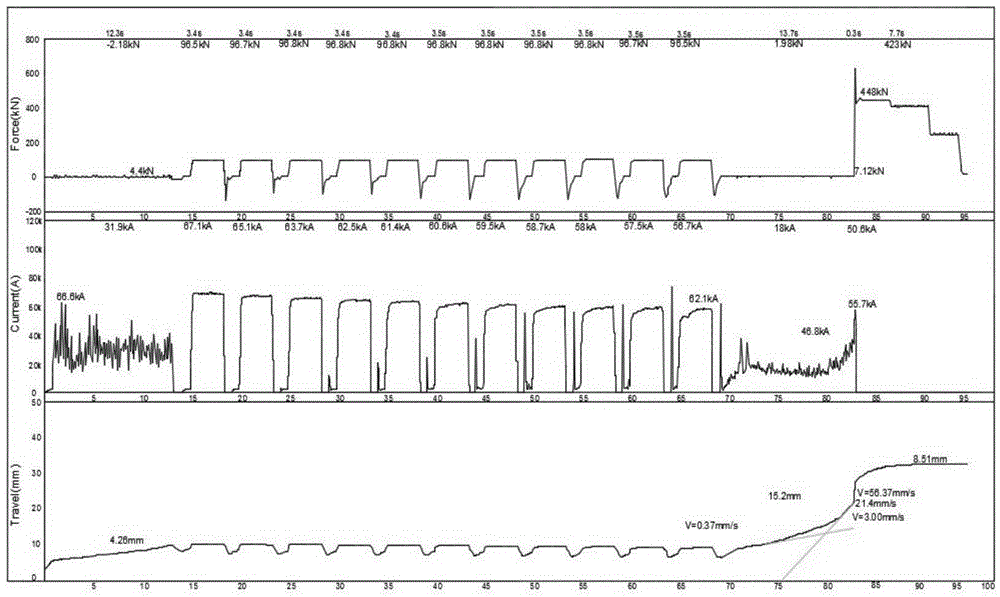

[0027] A rail welding method provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0028] As shown in Table 1, according to a welding method of the present invention, the method uses the same set of parameters to realize the welding of rails of different steel types.

[0029]

[0030] Table 1

[0031] Different steel rails have different mechanical properties and physical and chemical constants due to their different components. Welding two different rails together is more sensitive to the variable ratio of voltage, current, heating time and upsetting amount. The invention realizes mixed welding of three different steel rails of U71Mn, U75V and U76CrRe and mixed welding of U75V steel rails in different delivery states through common welding process parameters.

[0032] This welding method according to the present invention further comprises the following aspects:

[0033] 1. Use the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com