Closed-circuit crushing mill

A kind of grinding equipment and grinding technology, which is applied in the direction of grain processing, etc., can solve the problems of consumption and increased cost of circulating grinding equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

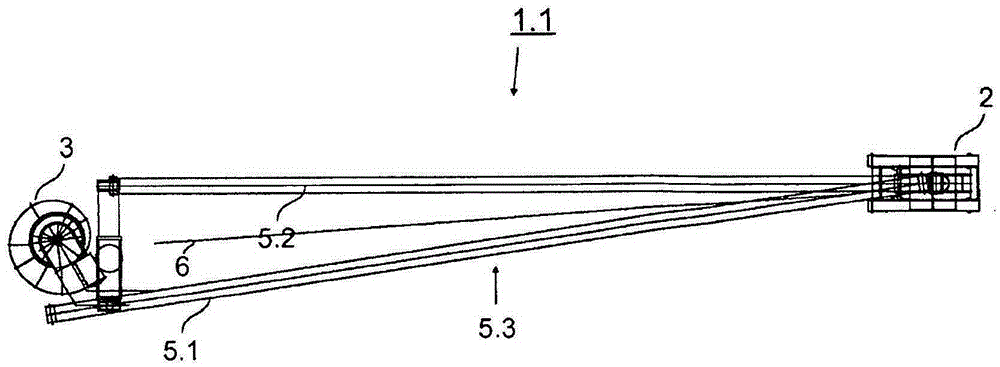

[0029] exist figure 1 The circular grinding plant 1 according to the invention is shown in side view with its three main mechanisms. The main mechanisms are a high-pressure roller press 2, a device 3 for screening fines from the circulating material 4 to be ground, and two devices 5.1 and 5.1 for conveying the circulating material 4 to be ground. 5.2. According to the invention it is provided that the high-pressure roller press 2 is spaced apart from a device 3 for screening fines from the circulating material 4 to be ground. The connection between these two institutions is through the figure 1 The two devices for delivery shown in 5.1 and 5.2 are realized. This transport of the material to be ground 4 from the respective one unit to the respective other unit always takes place upwards, so that the material to be ground circulates between the high-pressure roller press 2 and the device 3 for sieving. The fine material to be ground 4 is taken out of circulation by the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com