Connector terminal suitable for multi-directions

A machine-connected, multi-directional technology, applied in the direction of connection, parts of the connection device, electrical components, etc., can solve the problems of troublesome insertion, difficult to hold, etc., and achieve the effect of improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

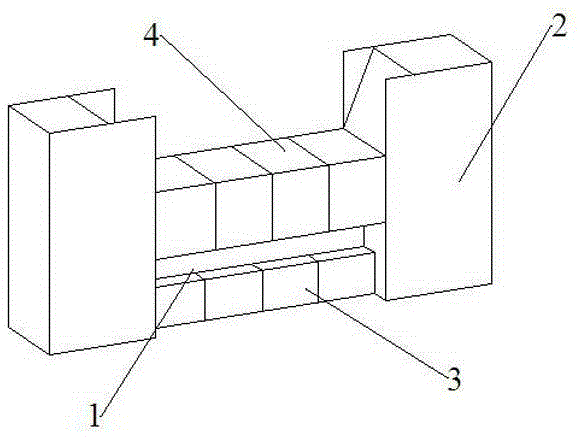

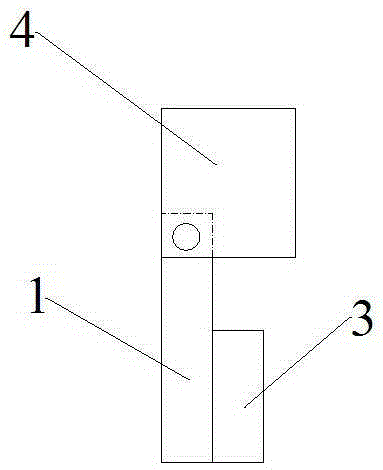

[0016] Such as figure 1 As shown, the present invention relates to a multi-directional connector terminal, including a terminal body 1, a guide module 2 and a jack module.

[0017] The guide modules 2 are arranged at both ends of the terminal body 1 . The guide modules 2 are arranged in a groove shape, and the distance between the guide modules 2 becomes gradually smaller along the direction from the outside to the socket module.

[0018] There are several sets of jack modules, and each set of jack modules includes a jack end 3 and an auxiliary guide hole 4 arranged outside the jack end 3 . The end of the auxiliary guide hole 4 is flexibly connected with the socket end 3 . The cross-section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com