Air conditioner performance detection system and method and standard machine weighing method

A detection system and standard machine technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as waste of resources, environmental pollution, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

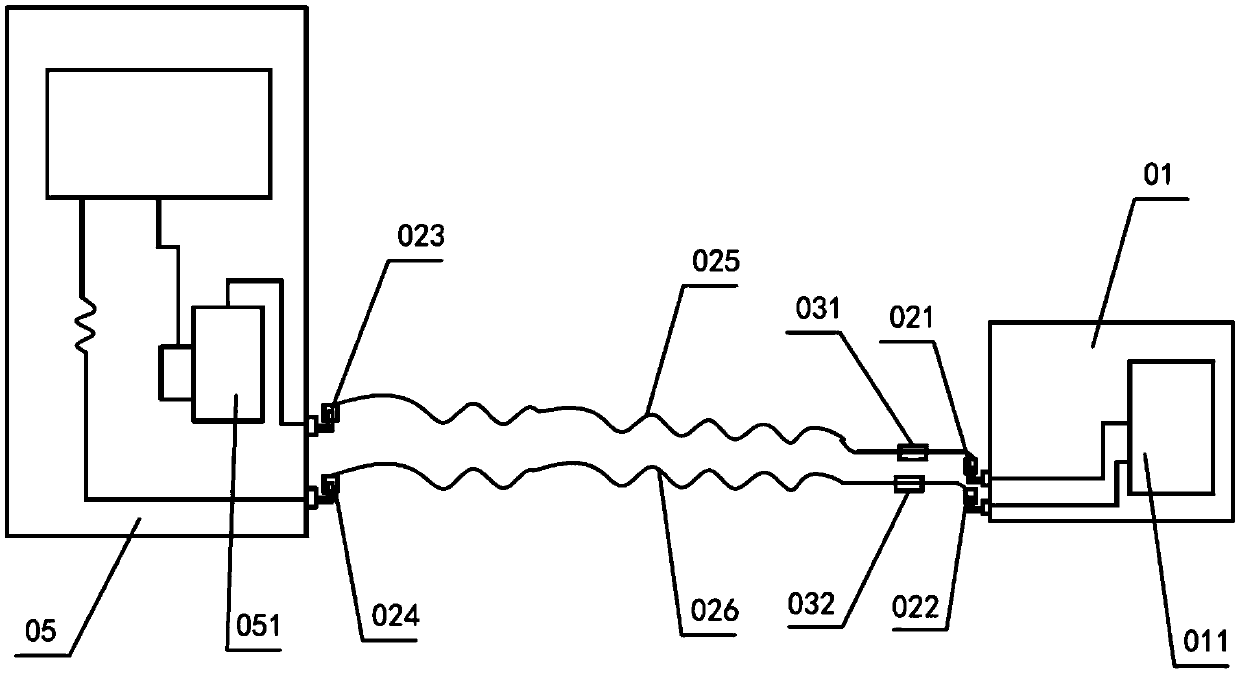

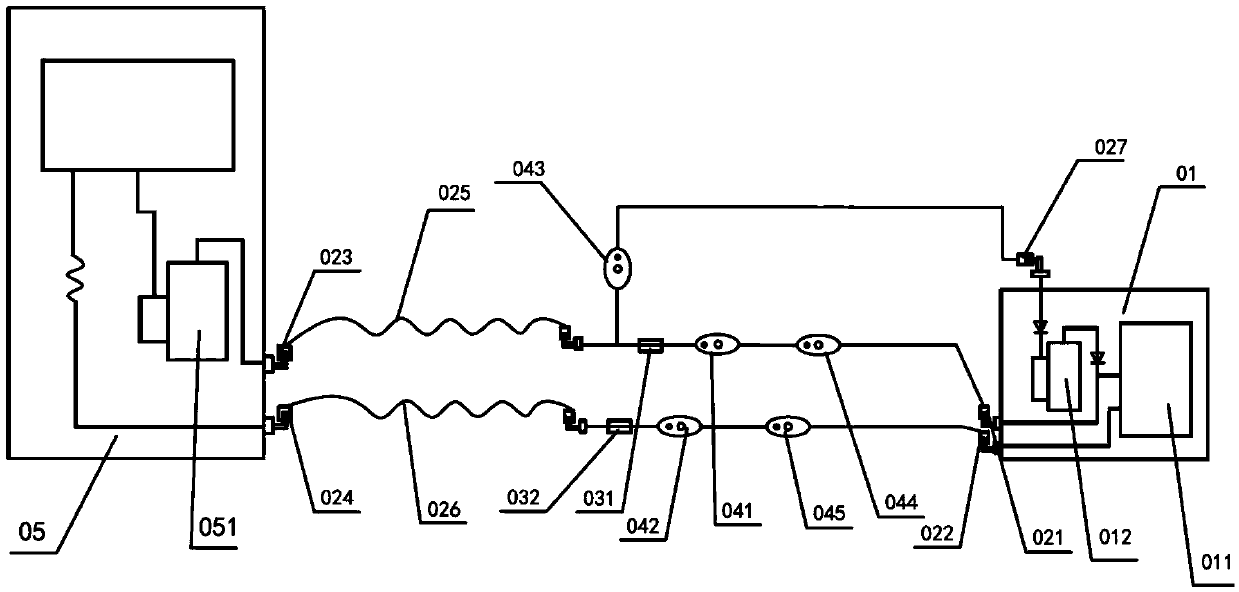

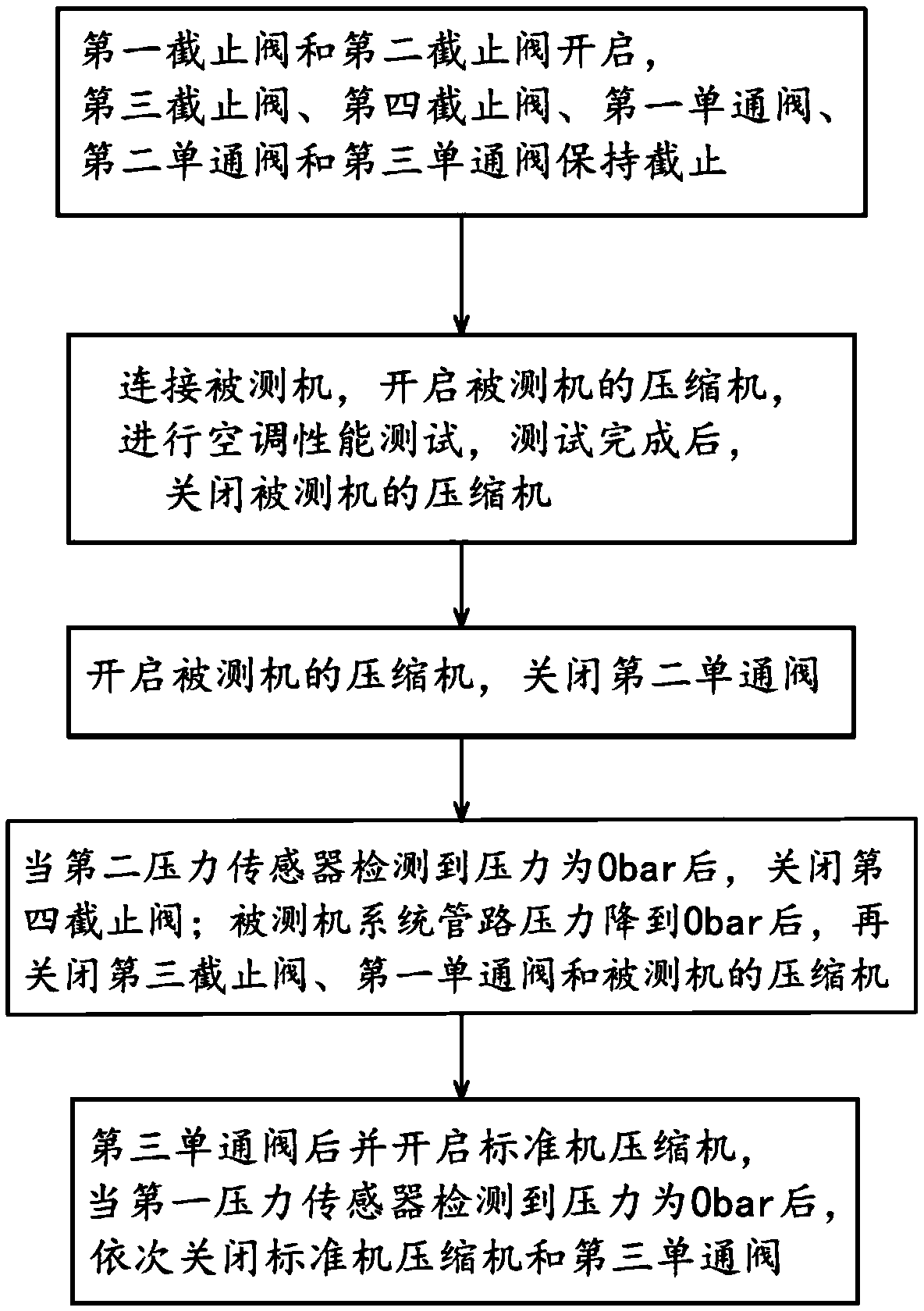

[0054] The structural diagram of the air-conditioning performance detection system of the present invention can be found in figure 2 , air conditioner performance testing system, including testing standard machine 01 and testing system piping, standard testing machine 01 is provided with a condenser 011, the condenser 011 includes a liquid input end and a gas output end, and the liquid input end is connected with a first cut-off valve 021 , the gas output end is connected with the second shut-off valve 022; the detection system pipeline includes the first pressure sensor 031, the second pressure sensor 032, the third shut-off valve 023 connected with the tested exhaust port of the tested machine and the tested The fourth cut-off valve 024 connected to the measured suction port of the engine, the first pressure sensor 031 is connected to the first cut-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com