Bushing tap pulse signal injection method-based transformer winding deformation detection device and method

A technology for transformer windings and monitoring devices, applied in electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve problems such as inability to inject online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

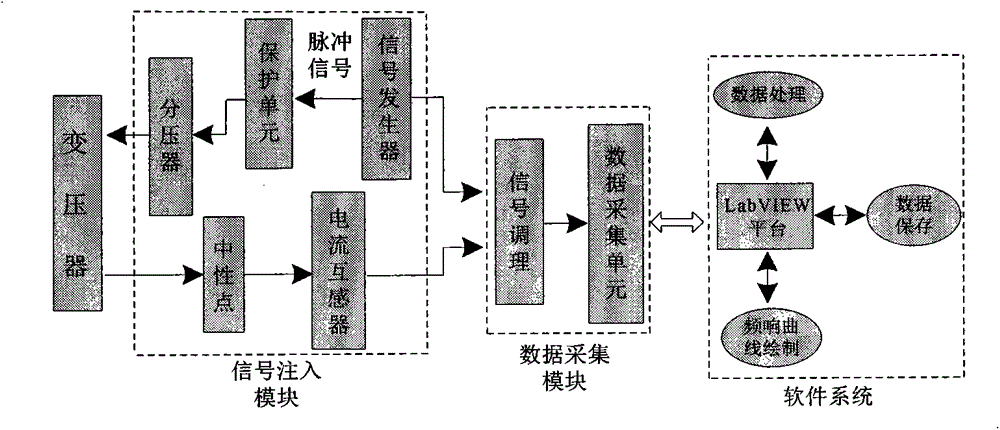

[0018] see figure 1 , the device uses a signal generator to inject a high-frequency pulse signal into the system, the signal enters the low-voltage winding of the transformer through a protection circuit and a voltage divider, and uses a high-frequency current sensor to measure the response signal at the neutral line. The response signal enters the industrial computer through the signal conditioning unit and the data acquisition card. The main hardware devices used in this system are as follows: pulse signal generator, protection circuit, capacitance sensor, high-speed data acquisition card, industrial computer. Using LabVIEW software to process the collected signal, the frequency response curve of the transformer winding is obtained, so as to judge the winding deformation of the transformer.

[0019] The signal source is the key and core part of the entire frequency response analysis detection system, and its parameters and performance determine the test effect of the monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com