A thread-free connection structure and layout of an air compressor exhaust pipe

An air compressor and connection structure technology, applied in the field of compressors, can solve the problems of insufficient flexibility in the layout of the compressor exhaust system, increase the number of processing procedures and installation procedures, and reduce the reliability of the entire compressor, so as to avoid Tighten the operating space of the installation wrench, improve the reliability of the whole machine, reduce the number of parts and the effect of the manufacturing process and the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

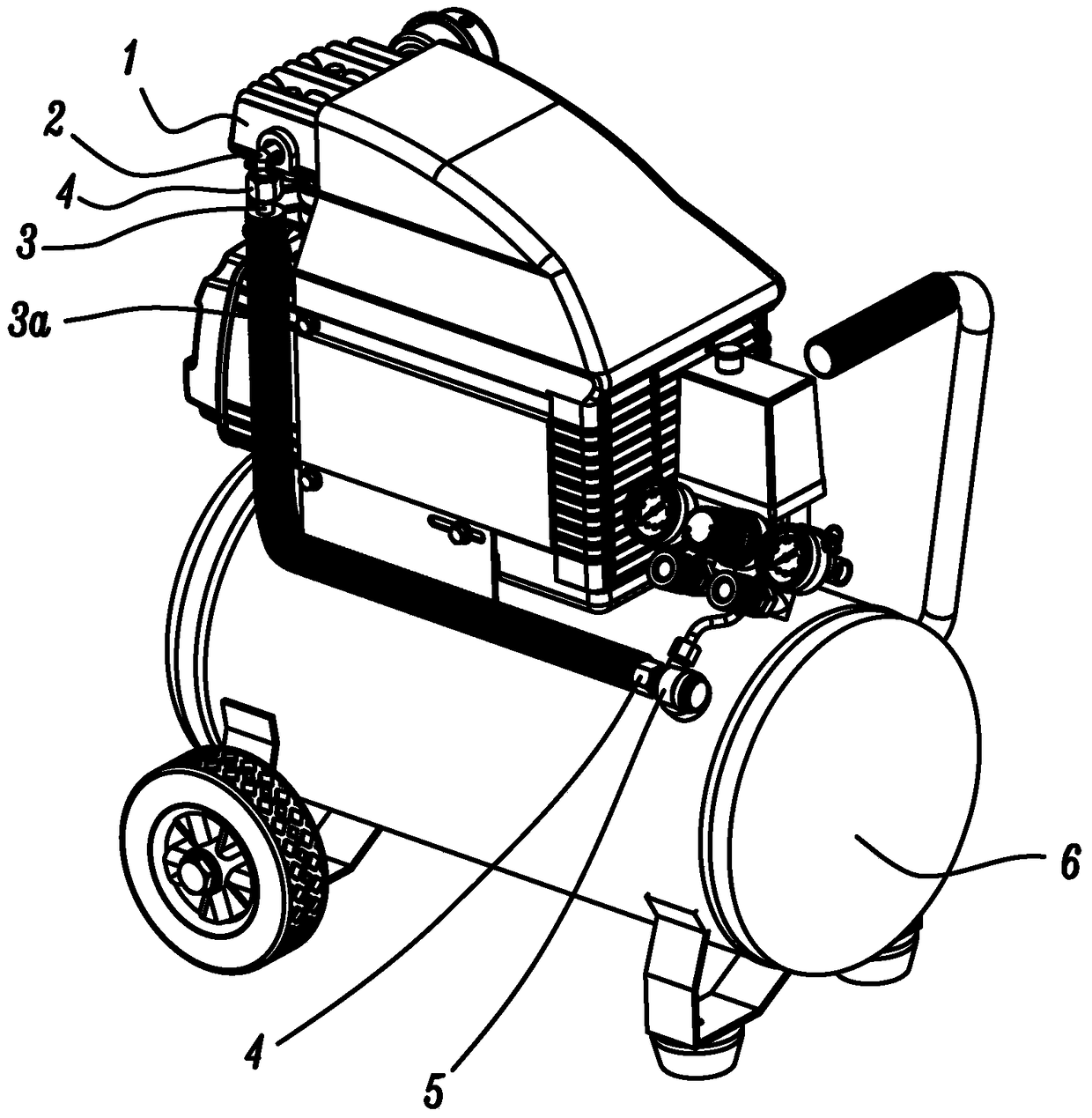

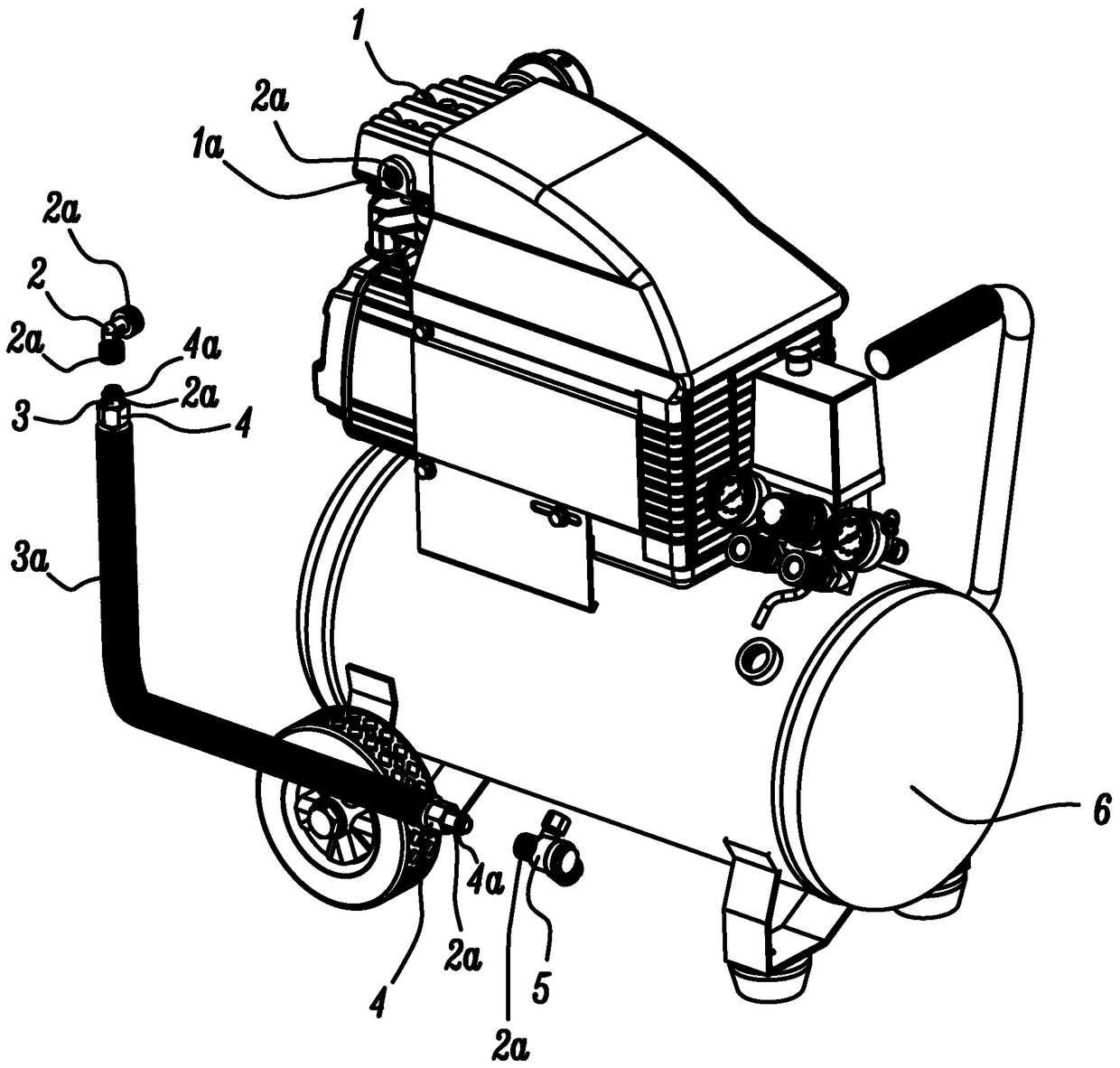

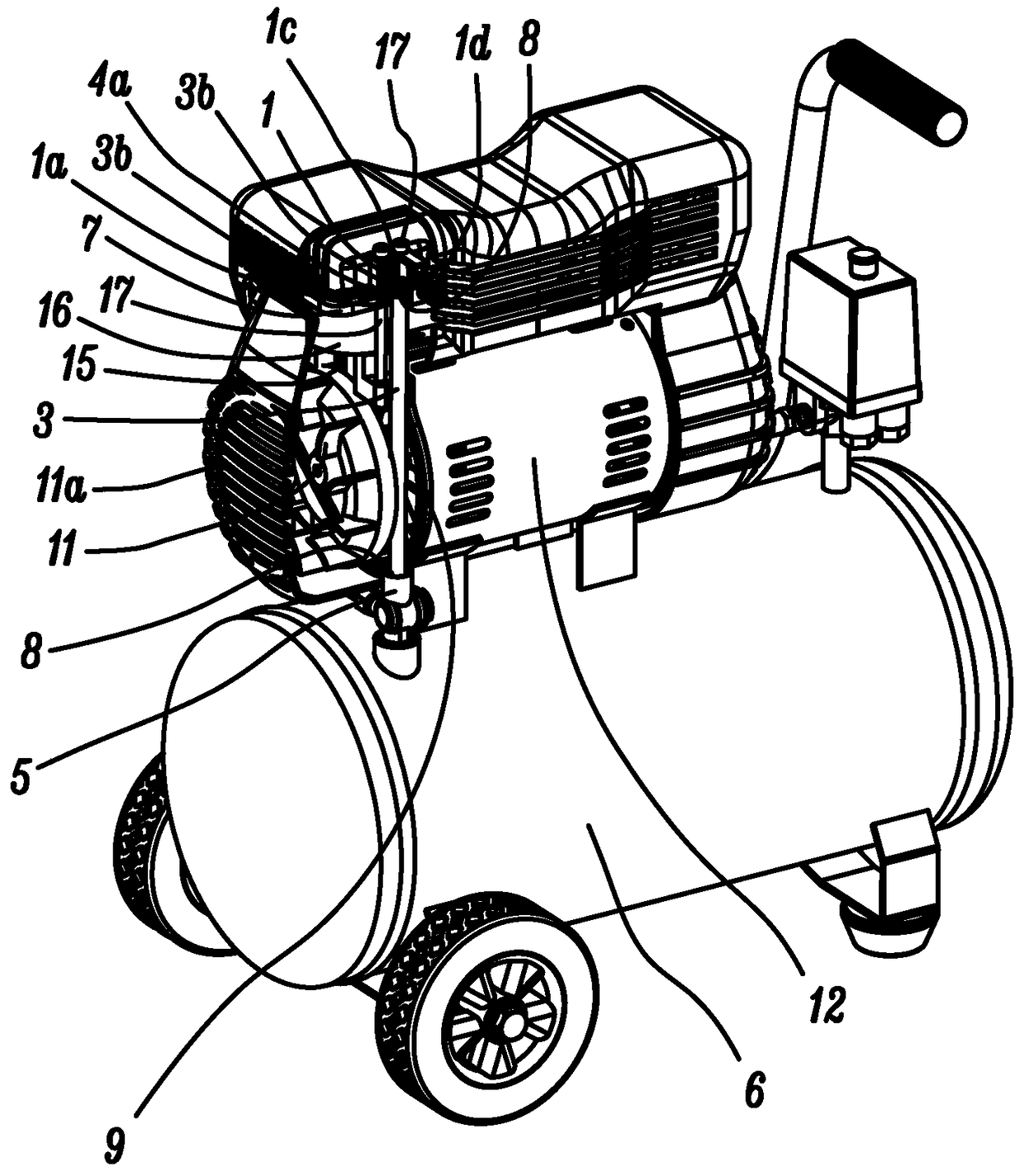

[0033] The present invention will be further described below with specific embodiment, see figure 1 -14:

[0034] A thread-free connection structure and layout of an air compressor exhaust pipe, including a cylinder head 1, an exhaust chamber 1b, a valve seat plate 7, and an exhaust port 1a set on the cylinder head 1 or / and valve seat plate 7 , exhaust pipe 3, pipe-through valve 5 and gas storage tank 6, wherein the exhaust port 1a communicates with the exhaust chamber 1b through the exhaust passage 1c, and the pipe-through valve 5 and the gas storage tank 6 can be directly connected or indirectly Connection (when it is an indirect connection, a section of transition pipeline or other components can be added between the pipe valve 5 and the gas storage tank 6), and the components that can control the conduction or cut-off of the gas path can be set in the pipe valve 5 (not shown in the figure), in addition, the valve seat plate 7 is used to arrange various air valves of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com