Method for controlling injection in combustion cycle of cylinder of internal combustion engine indirectly

An internal combustion engine, indirect technology, applied in the direction of internal combustion piston engine, combustion engine, engine control, etc., can solve the problems of inaccuracy and no economic advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

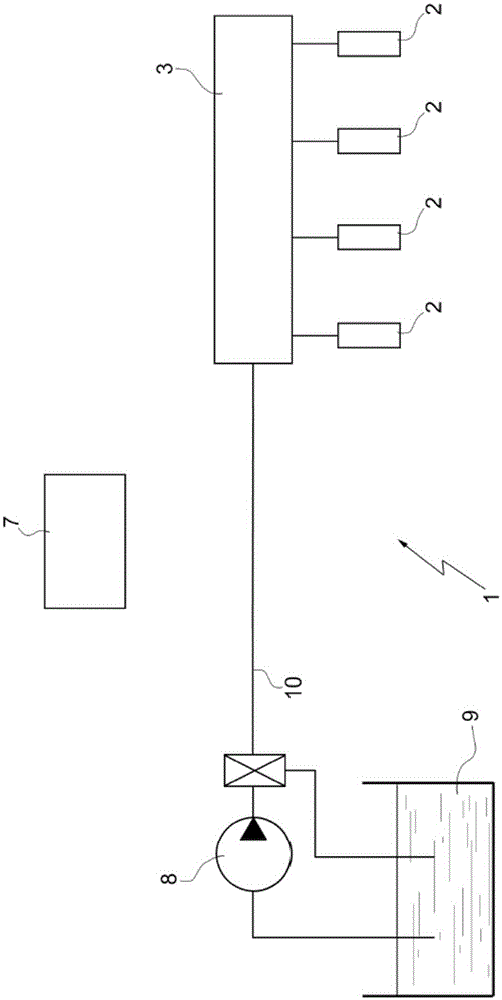

[0018] exist figure 1 Among them, in the case of an indirect fuel injection system suitable for an internal-combustion heat engine (ICE, internal-combustion heat engine), for example in the case of the PFI (Port Fuel Injection) type, it is designated by reference numeral 1 as a whole, which does not have a common A device for fuel recirculation between the rail and the fuel tank.

[0019] The indirect injection system 1 includes a plurality of injectors 2 , specifically four injectors 2 , and a common rail 3 that supplies fuel to the injectors 2 under pressure. The indirect injection system 1 also includes a low-pressure pump 8 that supplies fuel from a tank 9 to the common rail 3 through a supply line 10 .

[0020] Furthermore, the internal combustion heat engine ICE comprises a number of cylinders (not shown), preferably an even number, arranged in rows and each housing a corresponding piston mechanically connected to the crankshaft of the engine through connecting rods in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com