Pole foundation pitting rope wear, application thereof and pole foundation pitting method

A technology of pole and tower foundation and ropes, which is applied in the direction of foundation structure engineering, foundation structure test, construction, etc. The problem of high cost can reduce the cost of surveying and mapping, save manpower and material resources, and achieve the effect of high surveying and mapping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

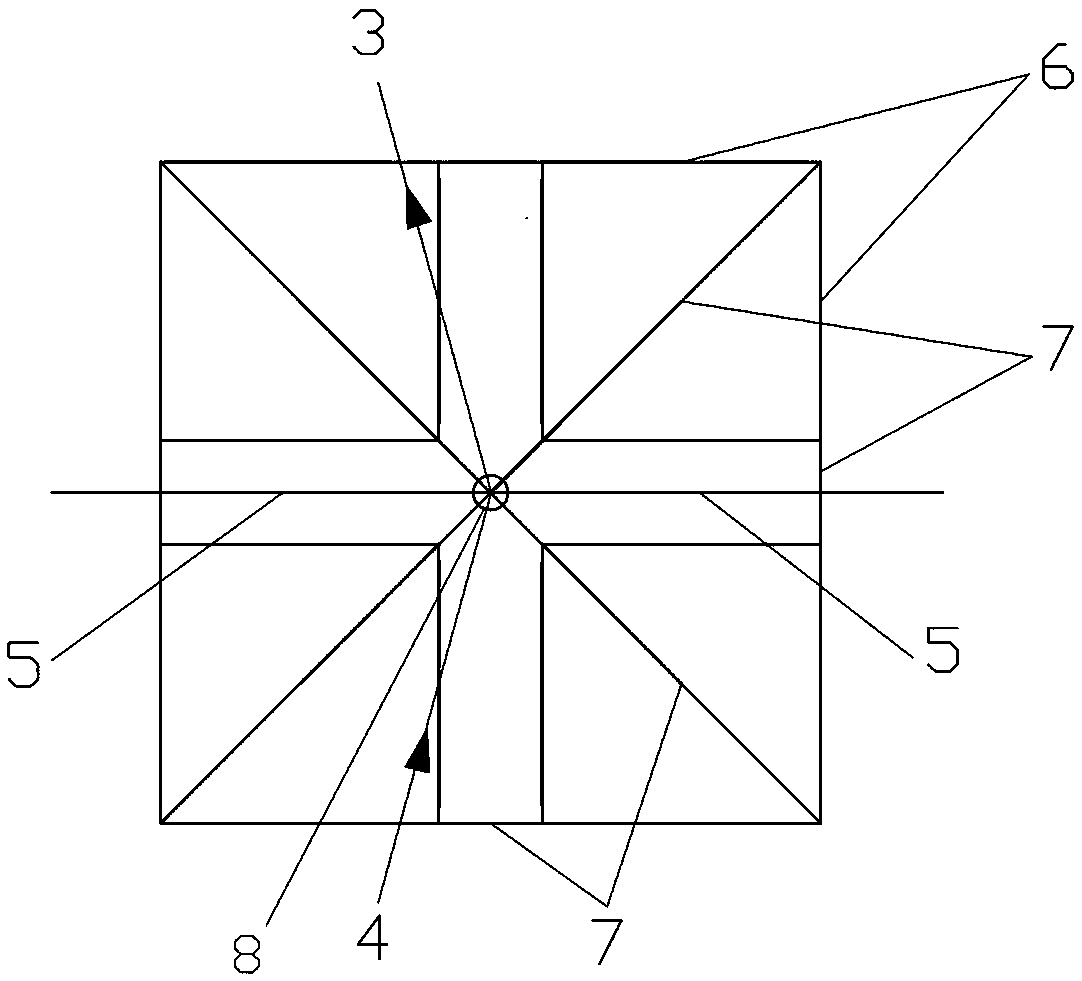

[0030] A kind of rope tool for pole and tower foundation pit division, which is a rope net formed by fixed connection of positioning wire rope, pit contour wire rope 6 and connecting wire rope 7, said positioning wire rope is provided with rope tool positioning point 8, so The positioning wire rope is an angle bisector wire rope 5, and the positioning wire rope is fixedly connected to the connecting wire rope 7, and is fixed in the rope net by the connecting wire rope 7, and it is a straight line after being unfolded; the pit position contour wire rope 6 There are several groups, which are divided into several groups. The number of groups is the same as the number of foundation pits that have been determined. In the same group, the contour lines 6 of each pit position are fixed and connected in turn to form a closed figure. The pit mouth contour figure, the pit position contour line rope 6 of each group is fixedly connected to the connection line 7, and is fixed in the rope net...

Embodiment 1

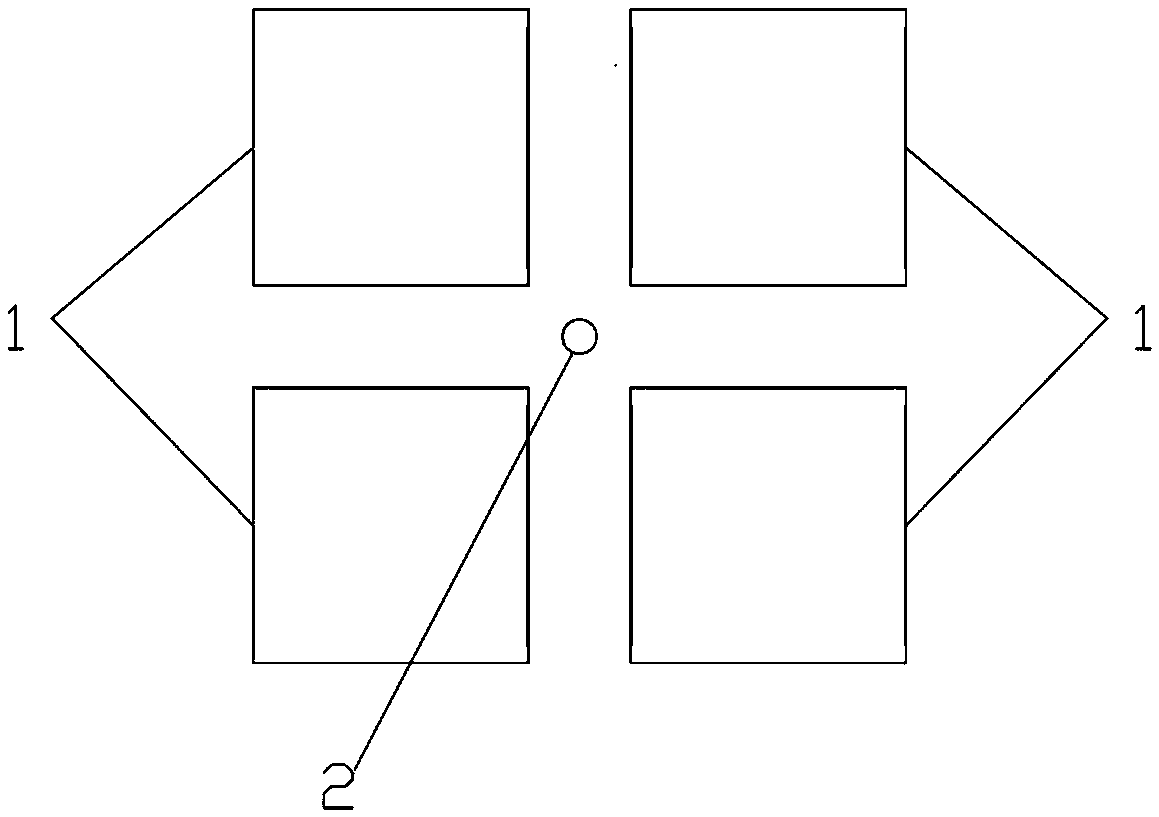

[0038] A kind of pit-dividing rope for tower foundation, see figure 2 , the foundation pit of the tower is as follows figure 1 As shown in the rectangle, there are 16 pit contour lines 6, each set of four, and the first position is fixedly connected to form a closed figure, and it becomes a rectangle after unfolding; there are 6 connecting lines 7, of which 2 are connecting lines 7 It is a diagonal connecting line, and the diagonal connecting line passes through the anchor point 8 of the rope and is fixedly connected to the two sets of pit contour lines 6 in the diagonal direction, and the two sets of pit contour lines in the diagonal direction The near apex of the rectangle formed by the rope 6 near the anchor point 8 of the rope and the far apex away from the anchor point 8 of the rope are all fixedly connected on the diagonal connecting wires in the diagonal direction; the other four connecting wires 7 It is a side connecting wire rope, which is fixedly connected to the o...

specific Embodiment approach 2

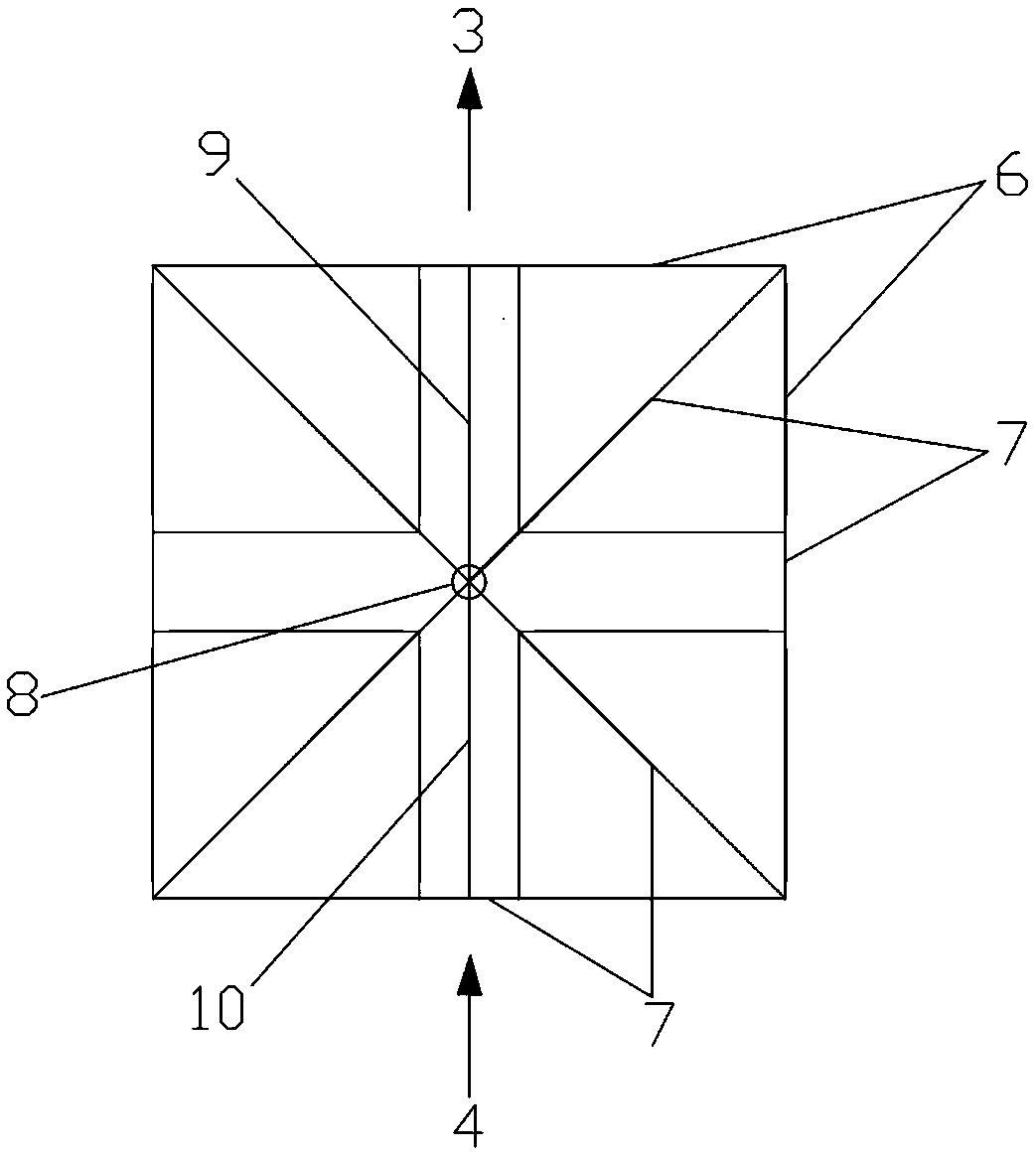

[0040] A kind of straight pole tower foundation pit-dividing rope, see image 3 , the power receiving side direction 4 and the power transmitting side direction 3 of the straight pole tower are located on the same straight line, and the rope is a rope net formed by fixedly connecting the positioning wire rope, the pit contour wire rope 6 and the connecting wire rope 7 , the positioning wire rope is the power transmission side direction wire rope 9 or the power receiving side direction wire rope 10, the positioning wire rope is provided with a rope positioning point 8, and the positioning wire rope is fixedly connected to the connection wire rope 7, by The connecting wire rope 7 is fixed in the rope net, and it is a straight line after it is unfolded; the pit position outline wire rope 6 is multiple, and is divided into several groups, and its grouping number is the same as the foundation pit number of the sub-pit that has been determined. Each pit outline line rope 6 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com