Belt conveyor

A technology of belt conveyors and conveyor belts, which is applied in the field of concrete production equipment, can solve the problems of large equipment damage, impact, and large damage to conveyor belts, and achieve good detection results, safety assurance, and wide field of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

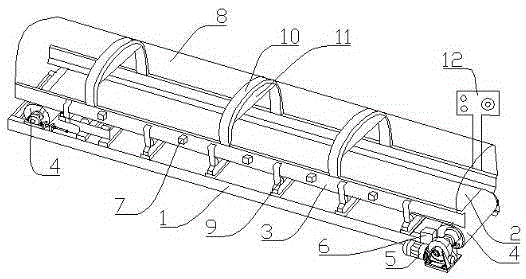

[0016] Reference attached figure 1 , the present invention provides a belt conveyor, comprising a base 1, a conveyor belt 2, a drive roller 4 and a motor 5, the drive roller 4 is arranged at both ends of the conveyor belt 2, and the base 1 is simultaneously positioned between the two drive rollers 4 A plurality of driven rollers 9 are arranged between them, and it is characterized in that limit plates 3 are arranged on both sides of the conveyor belt 2, and a protective cover 8 is arranged above the conveyor belt 2, and the protective cover 8 is U-shaped. 8. Transparent PVC material is used for easy observation of internal conditions;

[0017] A U-shaped support frame 10 is attached to the inner wall of the protective cover 8, and the two ends of the U-shaped support frame 10 are arranged on the limit plate 3, and the surface of the U-shaped support frame 10 opposite to the conveyor belt 2 is provided with an infrared A sensor 11 , an operation panel 12 is provided at one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com