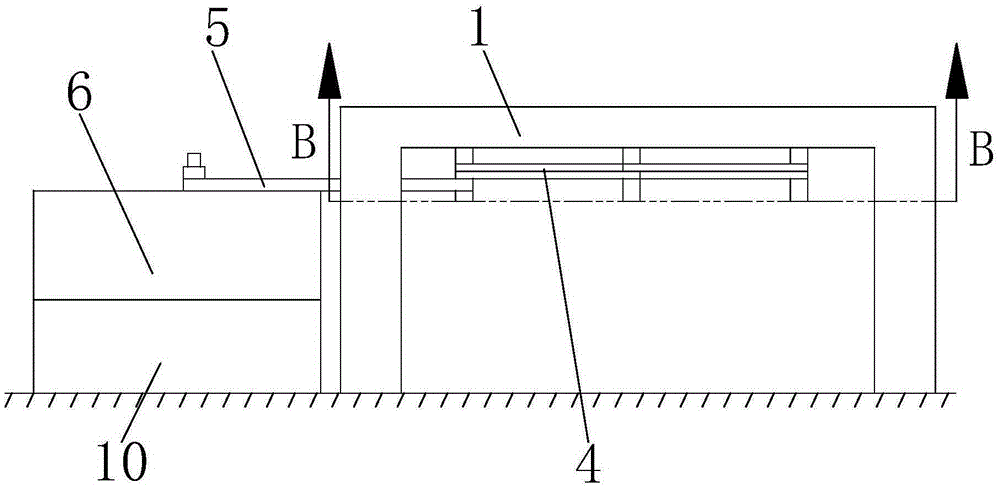

Universal valve body machining fixture

A clamp and valve body technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of single, narrow clamping valve body, etc., to achieve the effect of convenient use and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

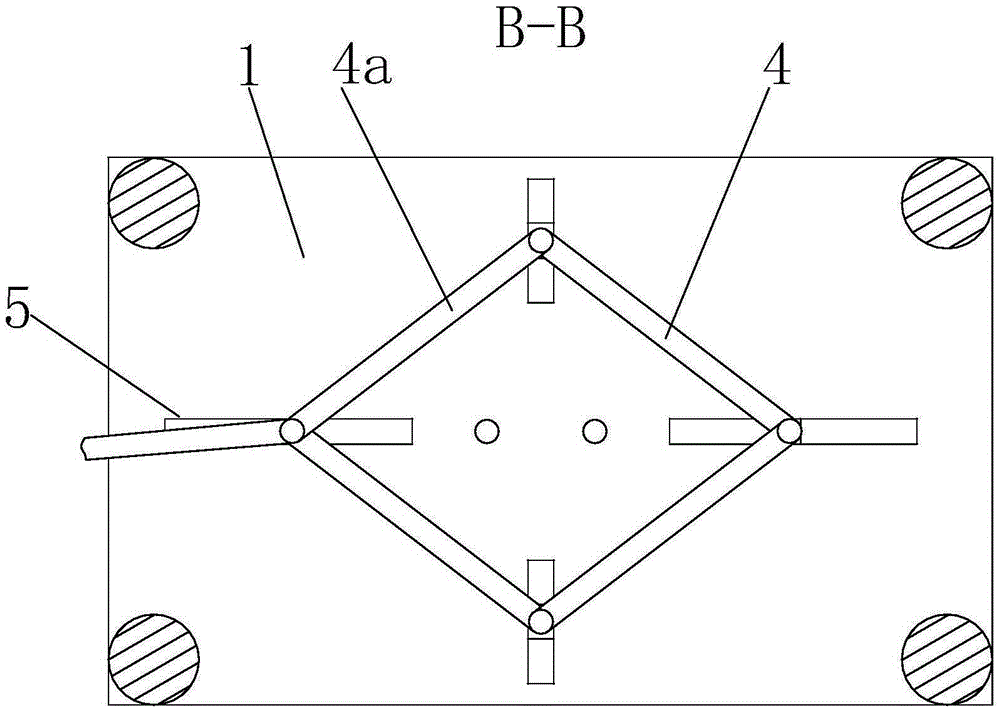

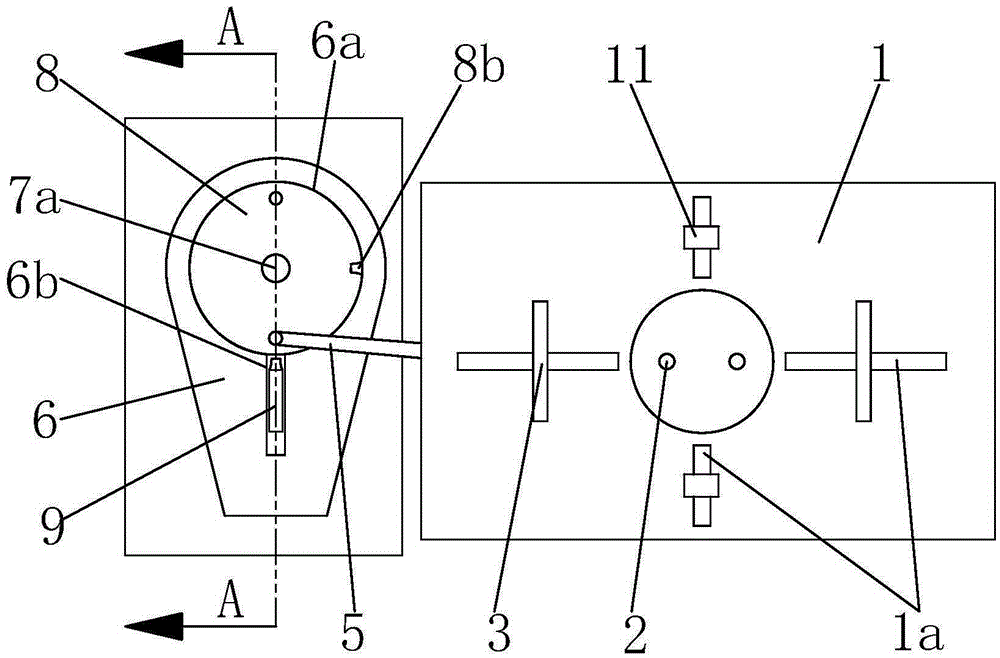

[0030] As the second embodiment of the present invention, the screw rod 7 can be rotated and pressed down first, and then the transfer wheel 8 and the control frame 6 can be connected into one body after being pressed down. When the input rotating handle 8c is rotated again, the The entire adapter wheel 8 rotates synchronously with the control frame 6 around the center of the control frame 6, and can also achieve the function of clamping or loosening the valve body. Wherein, the horizontal sliding distance of the two pressing plates 3 is twice the distance from the hinge point between the left end of the long connecting rod 5 and the transfer wheel 8 to the center of the control frame 6 .

[0031] It can be concluded from the above two implementations that the present invention can effectively control the horizontal sliding distance of the two pressure plates 3 , and can further adapt to clamping valve bodies of different sizes and models, and has wide application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com