Adjustable positioning welding clamp

A positioning welding and adjustable technology, applied in the field of tooling and fixtures, can solve the problems of not being able to use fast welding, not being able to improve production efficiency, and fixtures not being able to meet the needs, so as to improve welding efficiency and welding quality, facilitate processing, and facilitate rotary welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

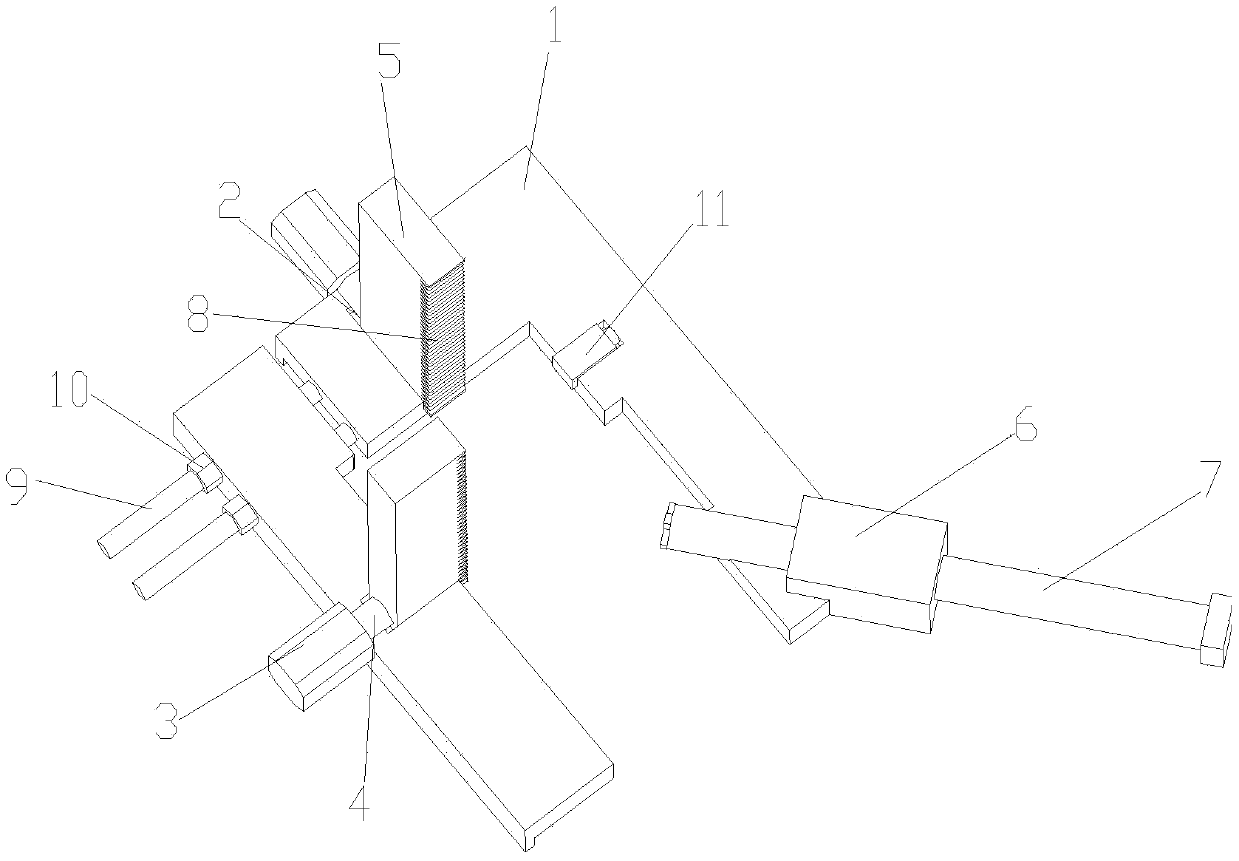

[0013] as attached figure 1 Shown is an adjustable positioning welding fixture according to the present invention, including a clamping plate 1; the upper surface of the clamping plate 1 is provided with moving grooves 2 horizontally and vertically; the moving groove 2 is equipped with a moving cylinder The clamping block 5 pushed by the piston rod 4 of 3, the clamping block 5 is provided with a locking tooth 8 on the inner side, which plays the role of increasing friction and anti-skid; the clamping plate 1 is also provided with a bolt fixing block 6 obliquely; The bolt fixing block 6 is provided with an adjustable locking bolt 7, and the top of the locking bolt 7 is cross-shaped, which reduces the stressed area, increases the pressure, and better fixes the product; the clamping plate 1 is divided into two parts. part, and connected by the adjustment rod 10; one end of the adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com