Multi-component micro-droplet microfluidic chip and its processing method

A microfluidic chip and micro-droplet technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve problems such as the inability to realize multi-component micro-droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

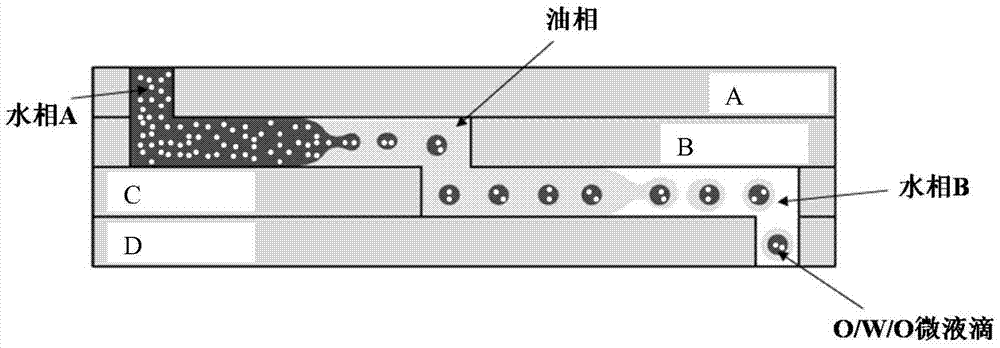

[0062] figure 2 It is a schematic diagram of the cross-sectional structure and droplet generation of the oil-in-water-in-oil type (O / W / O) multi-component micro-droplet microfluidic chip prepared according to the present invention. Such as figure 2 As shown, the microfluidic chip is composed of capping layer A, hydrophobic chip layer B, hydrophilic chip layer C and base layer D stacked in sequence; 1:4 for high-speed stirring and as water phase A; use three injection pumps to inject water phase A, oil phase, and water phase B into the microfluidic chip of the present invention from the corresponding solution inlet with a flow ratio of 1:5:25 Middle; in the hydrophobic chip layer B, the oil phase shears the water phase A from both sides, and the water phase A is sheared into a series of water-in-oil micro-droplets; the water-in-oil micro-droplets are formed by the hydrophobic chip layer B The micro-droplet generation chamber in the continuous phase flows into the lower hydro...

Embodiment 1

[0069] Example 1: Microfluidic chip for preparing O / W / O multi-component micro-droplets

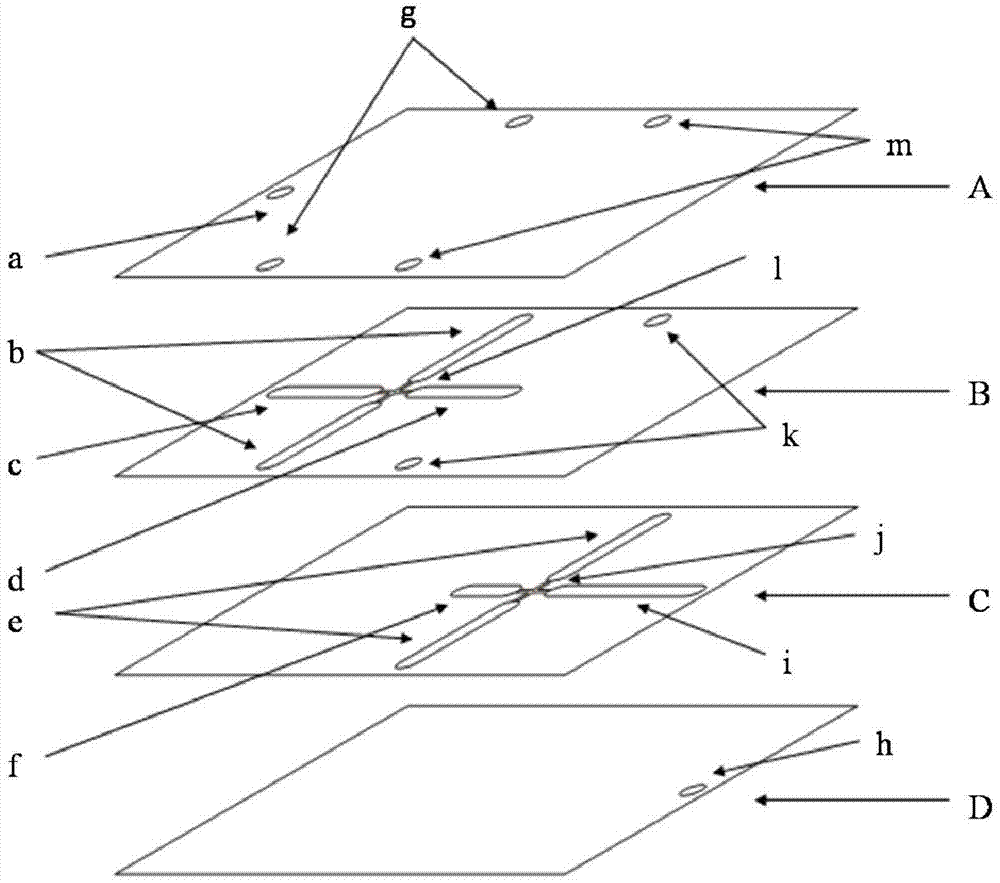

[0070] The multi-component micro-droplet microfluidic chip is prepared from polymethyl methacrylate substrate using laser engraving combined with sol-gel surface modification and thermocompression bonding. Its structure is as follows: figure 1 shown.

[0071] The oil-in-water-in-oil type (O / W / O) multi-component micro-droplets were prepared by using the above-mentioned microfluidic chip. The preparation process is as figure 2 shown. The oil phase (n-octane) and deionized water added with water-based dye (0.1% methyl orange solution) were stirred at a high speed at a volume ratio of 1:4 (stirring speed was 25,000 rpm, stirring time was 5 minutes) and used as the water phase a. Using three syringe pumps, water phase A, oil phase (n-octane), water phase B (deionized water) are imported into the microfluidic chip from the corresponding solution with a flow ratio of 1:5:25; In the chip l...

Embodiment 2

[0072] Example 2: Preparation of O / W / O multi-component magnetically responsive micro-droplet microfluidic chip

[0073] Will Fe 3 o 4 Nanoparticles (3 g) and deionized water (5 mL) were stirred at high speed at a stirring speed of 18000 rpm for 5 minutes to obtain an aqueous phase A. The 1,6-hexanediol diacrylate solution (10 mL of 1,6-hexanediol diacrylate solution, PGPR900. 5g) As an oil phase, a glycerol solution (20 mL of deionized water, 1 g of glycerol, and 0.2 g of F-127) added with surfactant F-127 (Sigma-Aldrich Co. LLC.) was used as an aqueous phase B. Use three syringe pumps to inject the above-mentioned water phase A, oil phase, and water phase B into the microfluidic chip at a flow rate ratio of 1:4:16; in the hydrophobic chip layer, the water phase A is sheared by the oil phase into a series contains Fe 3 o 4 Micro-droplets of nanoparticles; the above-mentioned micro-droplets flow into the lower hydrophilic chip layer from the micro-droplet generation cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com