Chassis suspension arm for a vehicle and method for producing a chassis suspension arm

A technology for controlling arms and chassis, applied to vehicle components, cantilever mounted on pivots, transportation and packaging, etc., can solve problems such as large costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

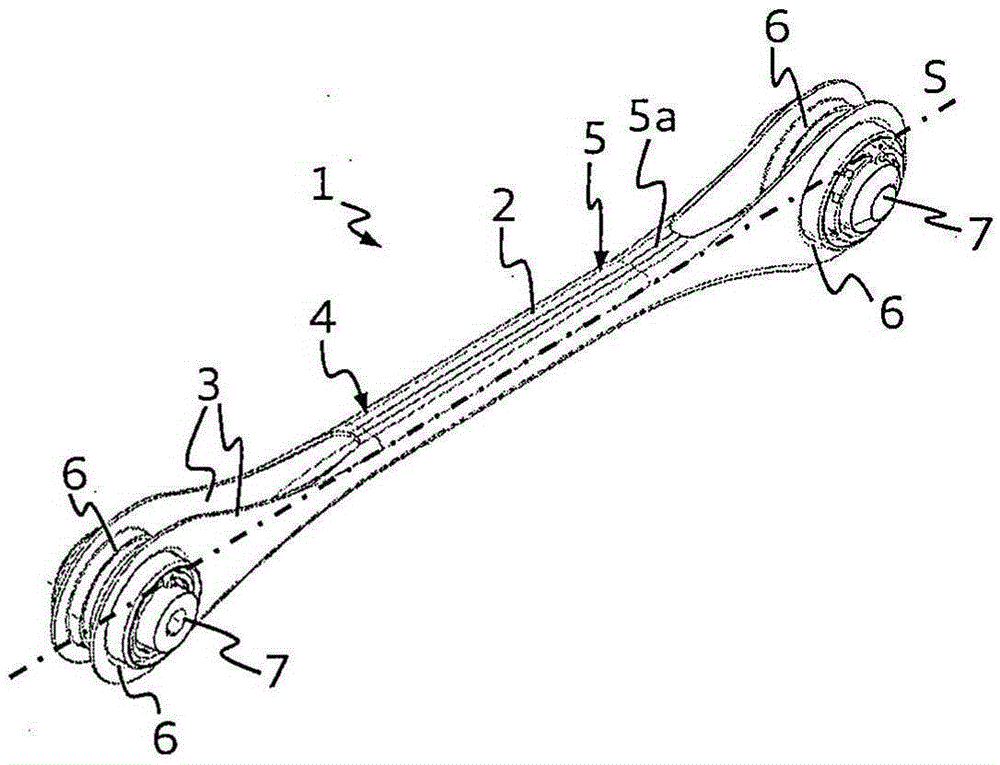

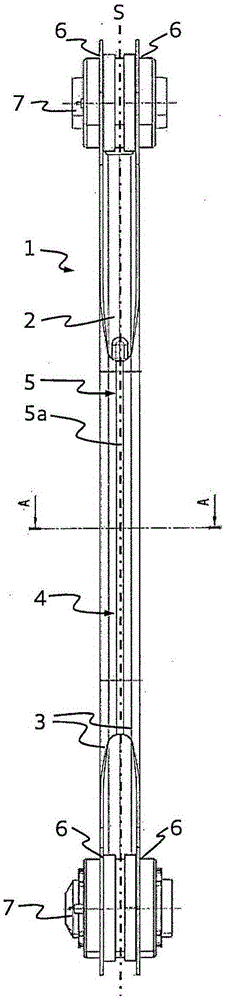

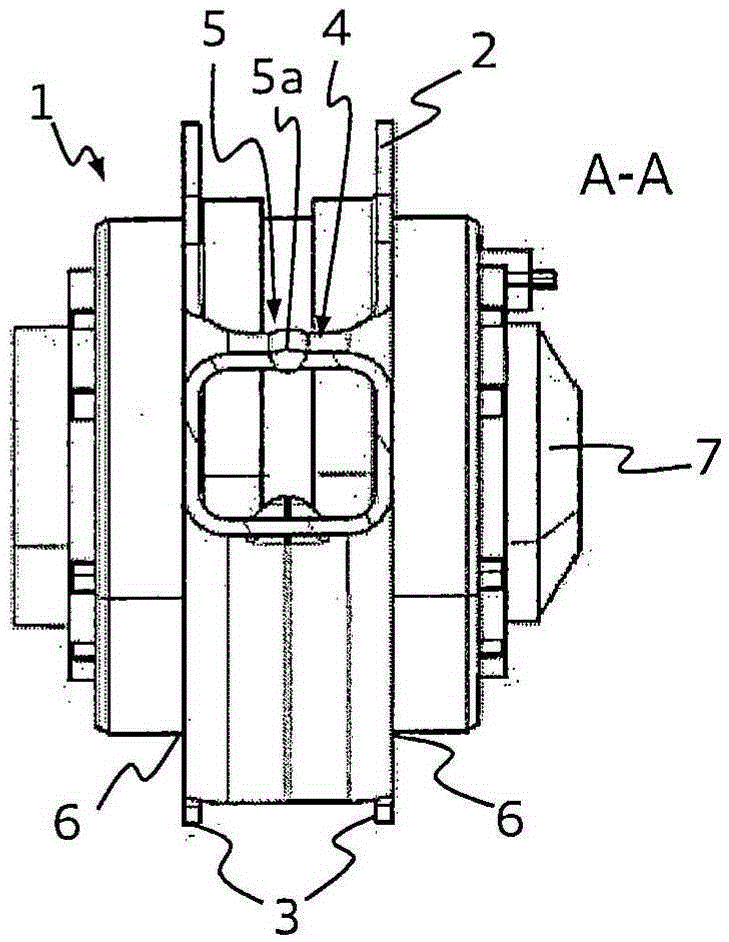

[0030] according to figure 1 , figure 2 and image 3A first embodiment of a chassis control arm 1 for a vehicle has a control arm body 2 with two spaced apart opposite side walls 3 which are integrally connected to each other on the longitudinal sides and On their opposite free longitudinal sides 4 , they are connected to one another by means of joining structures 5 . The joining connection 5 is represented in the exemplary embodiment by a partial welded connection 5 a. The control arm body 2 is produced from sheet metal by forming it about its axis of symmetry S using bending technology. On the axial ends of the control arm body 2 , coaxial bearing holes 6 are machined into the side walls 3 , which are respectively used to receive rubber-metal bearings 7 . The torsional rigidity of the control arm body 2 is greater than the gimbal stiffness of each individual rubber-metal bearing 7 due to the jointed connection 5 , and is lower without the jointed joint 5 .

[0031] acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com