Waterproof, dustproof and anti-static button structure

A button and electrostatic technology, applied in circuits, electrical switches, electrical components, etc., can solve problems such as failure to achieve protective effects, increase installation difficulty, and complex processes, achieve enhanced waterproof, dust-proof, and anti-static effects, and increase creepage. The effect of distance and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

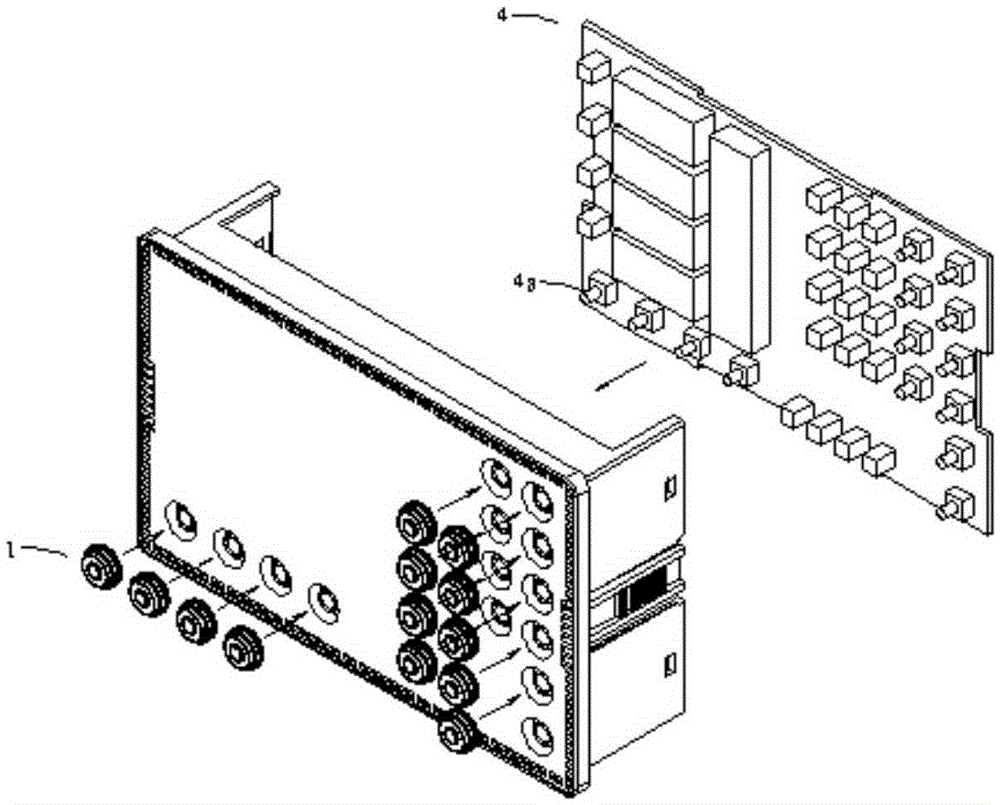

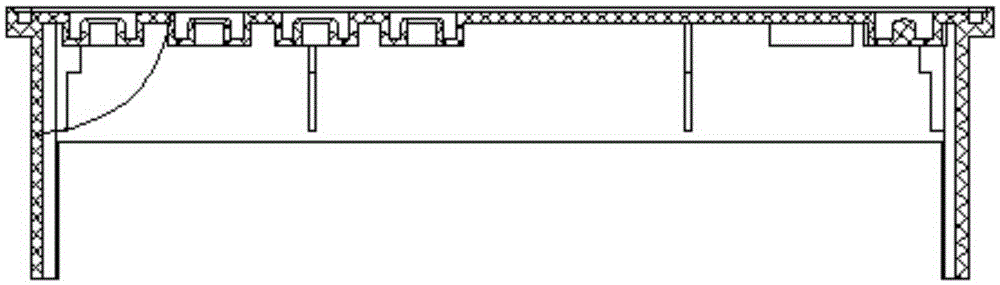

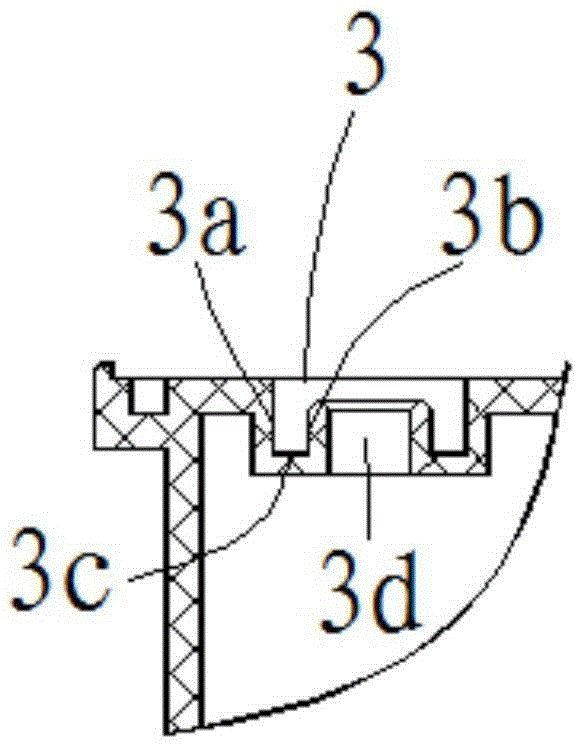

[0044]A waterproof, dustproof and antistatic button structure, including a surface frame 2 and a button 4a, and also includes a button cap 1 and a film panel 5; the front of the surface frame 2 has a receiving structure 3 for socketing the button cap 1, and the button 4a passes through The button channel 3d of the containing structure 3 is in contact with the button cap 1; The button cap 1 is sleeved on the containing structure 3, and then covered by the film panel 5, so as to play an initial role of waterproof, dustproof and antistatic, and increase reliability. After the button cap 1 is socketed, it can only be taken out from the front of the face frame 2, and the front is covered by the film panel 5, so it is not suitable to fall off, which saves the processing technology. The accommodating structure 3 includes a ring groove, the inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com