Design method for common-mode electro-magnetic interference filter for motor drive system

A motor drive system, electromagnetic interference technology, applied in the direction of instrumentation, calculation, electrical digital data processing, etc., can solve the problem that the optimal topology cannot be selected, and achieve the effect of accurate design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

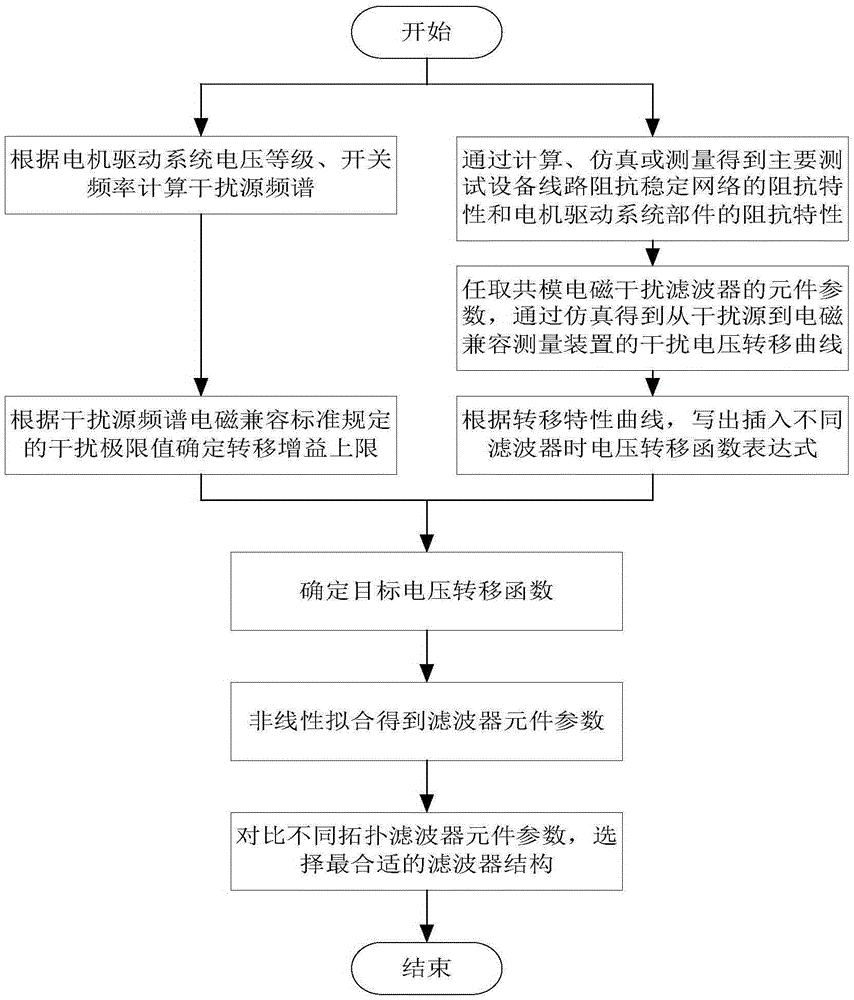

Method used

Image

Examples

Embodiment

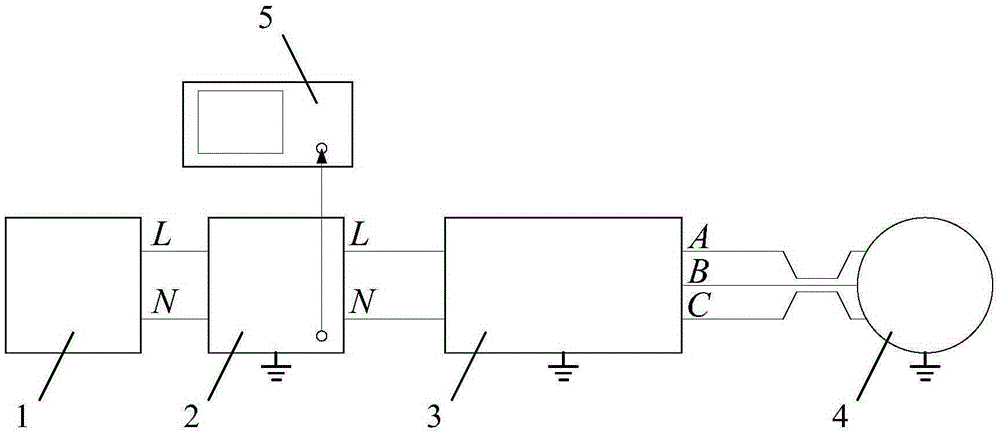

[0145] This embodiment adopts the method of the present invention to design input and output side common mode filters for a motor drive system.

[0146] The motor drive system includes a commercial DC power supply 1, a 30kW motor controller 3, a 20kW permanent magnet synchronous motor 4, a line impedance stabilization network 2 (manufactured by Schwarzbeck, Germany, model NNLK8130), and an electromagnetic interference receiver 5 (Manufactured by Rohde&Schwarz, Germany, model ESL3), a coaxial cable with a characteristic impedance of 50Ω, and several other power cables for power transmission. Without filter, the motor drive system is connected as figure 2 Shown.

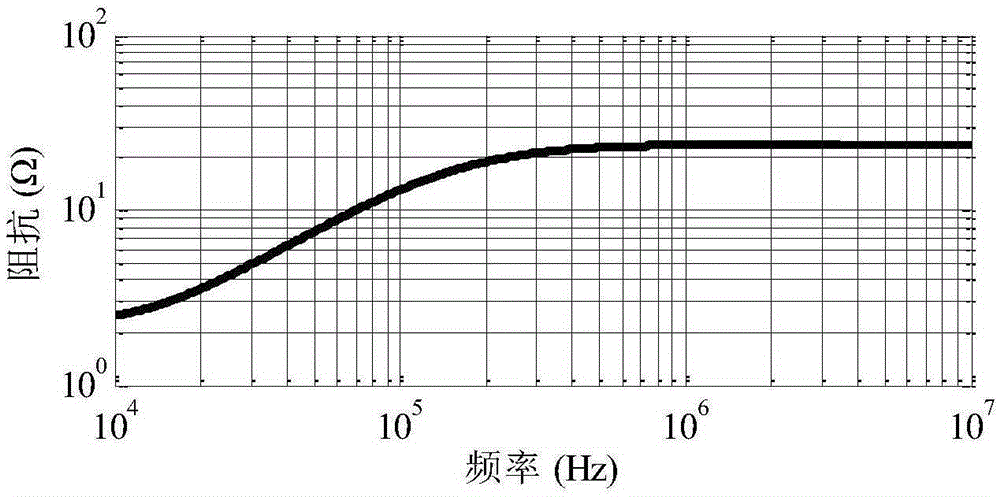

[0147] (1) Determine the impedance characteristics of the main equipment and components in the electromagnetic compatibility test of the motor drive system

[0148] The impedance characteristics of the line impedance stabilization network 2 are obtained by calculation as image 3 As shown; the impedance characteristics of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com