Plate wheel nickel-based platen thread lock pin step clamping plate glass verifying device

A technology of inspection device and disk wheel, which is applied in the direction of testing the strength of materials with one-time impact force, can solve the problems of uneven force around the surrounding, long time-consuming, and operator injury, so as to save the cost of testing consumables and improve personal safety. The effect of guaranteeing and shortening the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

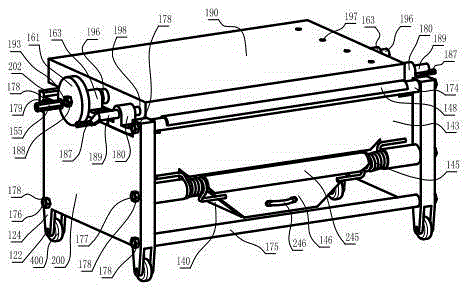

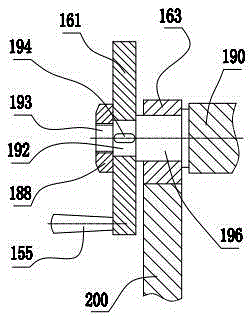

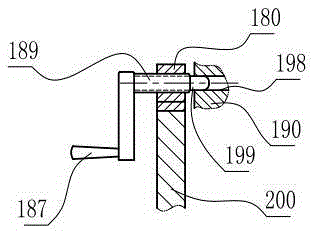

[0049] figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 , Figure 9 , Figure 10 ,and Figure 12 Middle: The disc-wheel nickel-based platform thread lock pin stepped plywood glass inspection device, including the test platform 190 and the plate frame 200, and the frame front pull-up rod 174 and the frame front pull-down rod between the two plate frames 200 175 and frame rear pull-down rod 176 and frame rear pull-up rod 179, frame front pull-up rod 174 and frame front pull-down rod 175 and frame rear pull-down rod 176 and frame rear pull-up rod 179 two ends all have tie rods Nuts 178 fix the two plate racks 200. As an improvement: there are platform rotating shafts 196 on both sides of the test platform 190, and the platform rotating shafts 196 on both sides are rotatably fixed in the platform support 163 respectively. The plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com