Self-centering rotary detection table

A technology of rotation detection and self-centering, which is applied in the direction of measuring devices and instruments, can solve the problems of tolerance in the inner hole of the wheel, inflexible rotation of the wheel body, and difficulty in concentricity inspection, so as to achieve short production period, improve inspection efficiency and The effect of accuracy and ease of procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

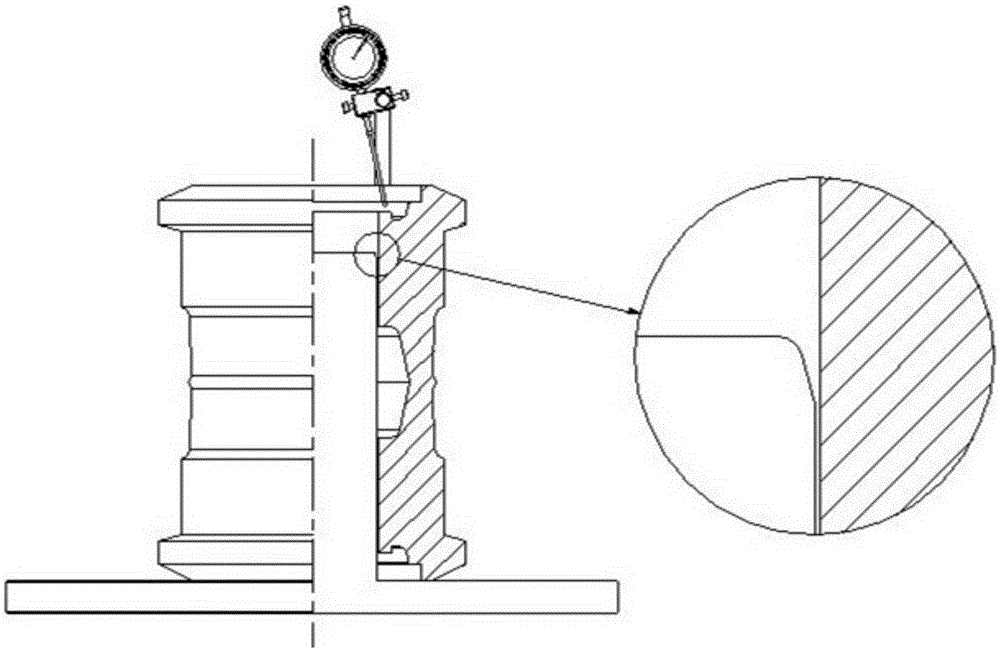

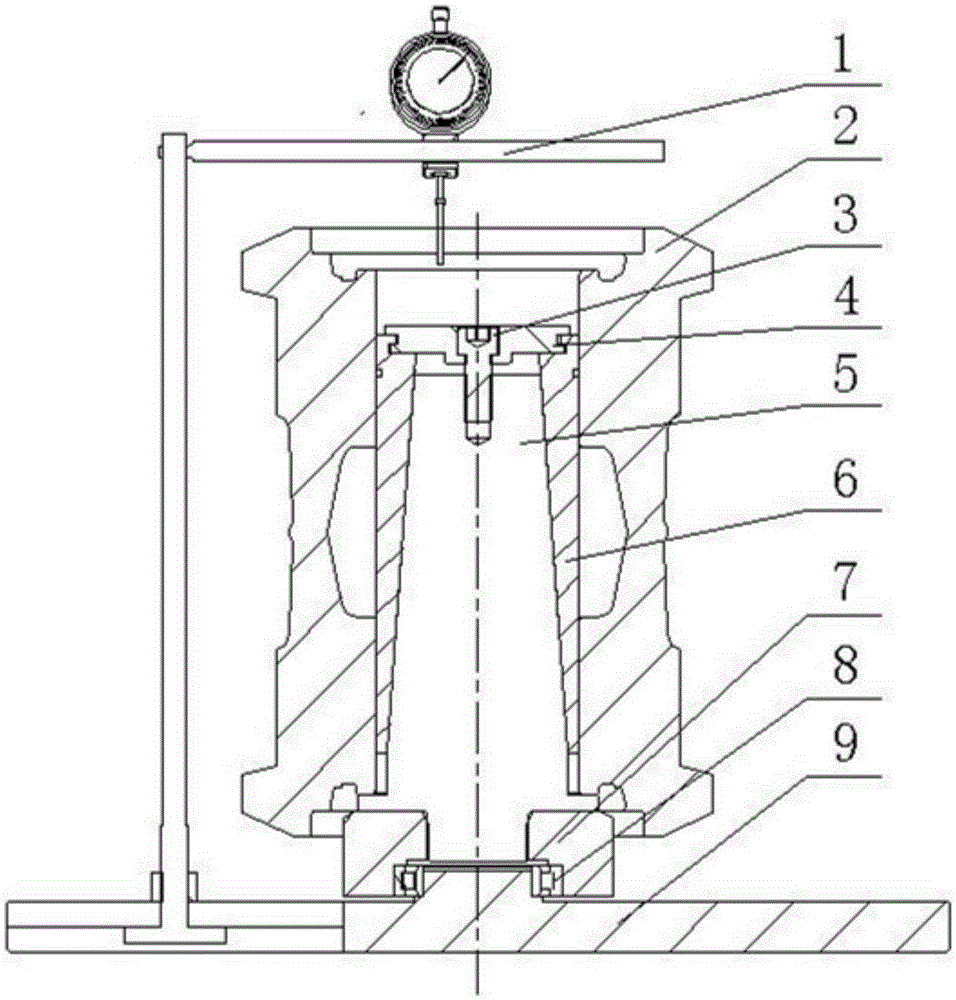

[0021] Such as figure 2 , image 3 As shown, the self-centering rotary detection platform includes a table frame 1, an expansion and opening gland 4, a tensioning column 5, an expansion jacket 6 and a chassis 9; Flexible rotation, preferably, the middle part of chassis 9 is installed with tensioning column 5 through positioning ring 7, bearing 8 rotation, bearing 8 is installed on the chassis 9, positioning ring 7 is sleeved on bearing 8, and the bottom of tensioning column 5 is installed on Inside the positioning ring 7. The tensioning column 5 is a conical structure, and the tensioning column 5 is covered with a tensioning jacket 6, and the tensioning jacket 6 is a hollow cylindrical structure, and the cavity is conical and matches the shape of the tensioning column 5 , the top of the expansion jacket 6 is equipped with an expansion gland 4, the expansion gland 4 is threaded with the expansion column 5 through the tightening screw 3, the expansion gland 4 has two function...

Embodiment 2

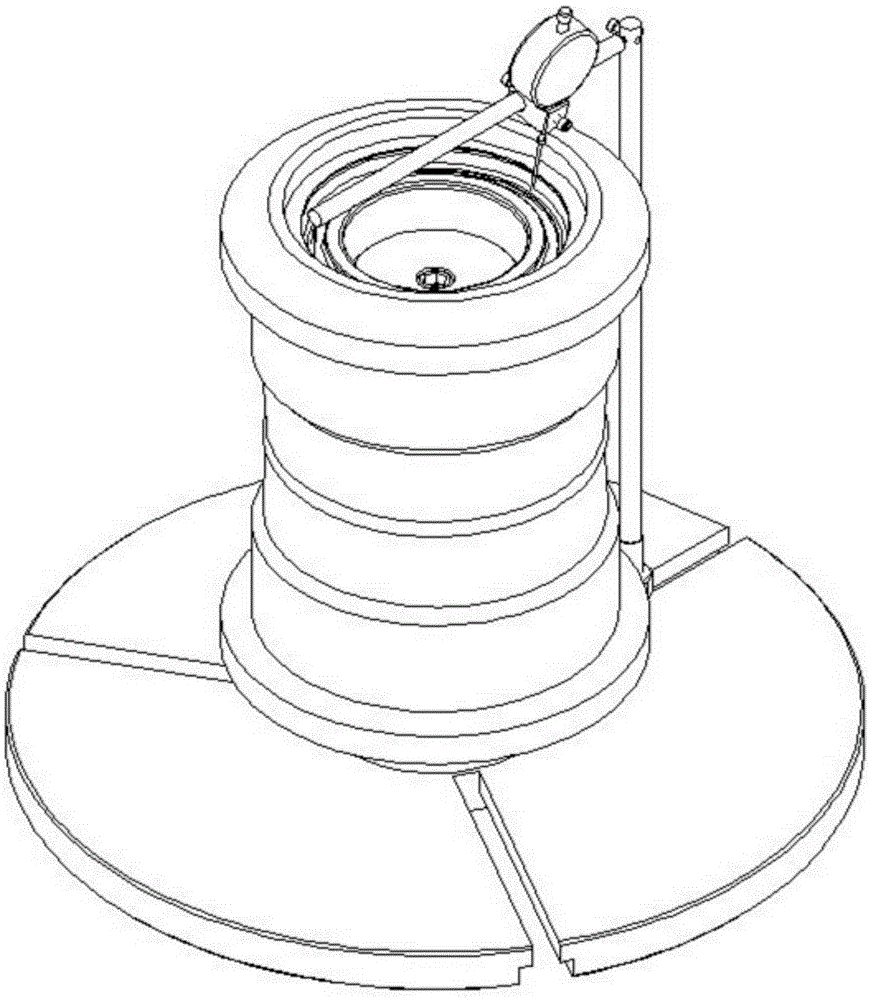

[0023] Different from Embodiment 1, such as Figure 4 , Figure 5 As shown in the figure, a meter head is installed on the vertical bar, which is used to detect the concentricity of the tread of the welded part of the double-sided roller body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com