Hybrid vehicle compound planetary gear set dynamic coupling mechanism

A technology of hybrid electric vehicles and planetary gear sets, which is applied in the field of automotive hybrids, can solve the problems of inconvenient control strategies, insufficient vehicle power performance, and high control requirements, so as to improve fuel consumption characteristics and power performance, and facilitate multi-mode control , the effect of control requirements reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

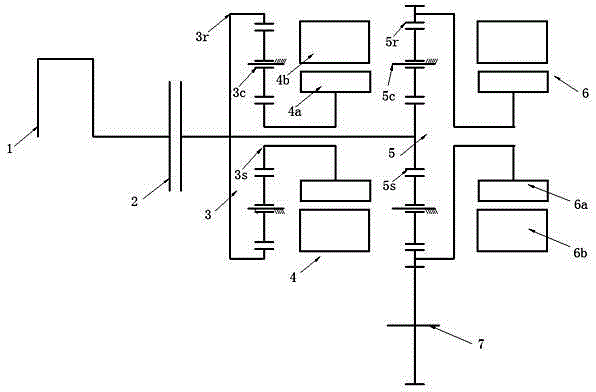

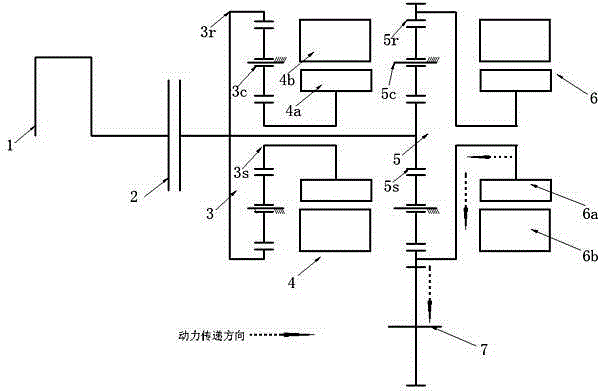

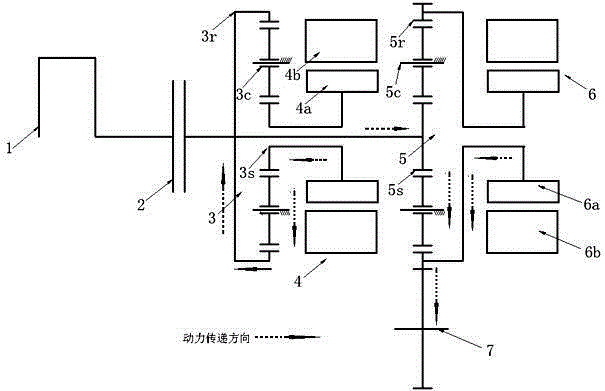

[0020] Such as figure 1 As shown, the compound planetary gear set power coupling mechanism of the hybrid electric vehicle includes an engine 1, a first planetary gear set 3, a second planetary gear set 5, a first motor 4 and a second motor 6; The gear set 3 is composed of the first sun gear 3s, the first planet carrier 3c, the first ring gear 3r and its planetary gears; the second planetary gear set 5 is composed of the second sun gear 5s, the second planet carrier 5c, the second The ring gear 5r and its planetary gears are formed; the first ring gear 3r of the first planetary gear set 3 is connected with the engine 1 through a clutch 2, the first planet carrier 3c is fixed on the vehicle frame, and the first A sun gear 3s is fixedly connected with the rotor 4a of the first motor 4; the second sun gear 5s of the second planetary gear set 5 is fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com