High-efficiency accurate-measurement positioning seeding method

A precise and high-efficiency technology, applied in the agricultural field, can solve the problems of a single hole with multiple seeds, high seed replenishment frequency, and high empty seed rate in the sowing hole, achieve efficient and precise positioning, reduce sowing costs, improve sowing quality and The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

[0026] Sow in a standard rice seedling tray, the size of the inner opening of the seedling tray is 28cm*58cm. The sown seeds are rape seeds, and the seed diameter of the sown rape variety is 2 mm. The seeding density is 800 grains per tray.

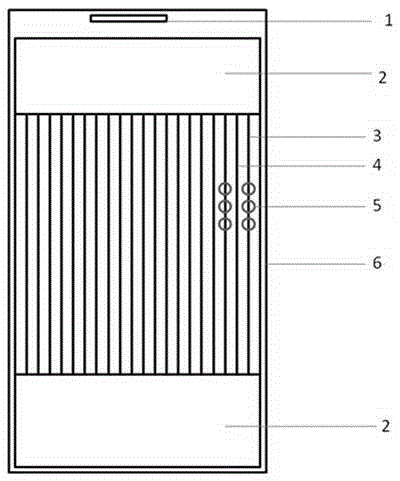

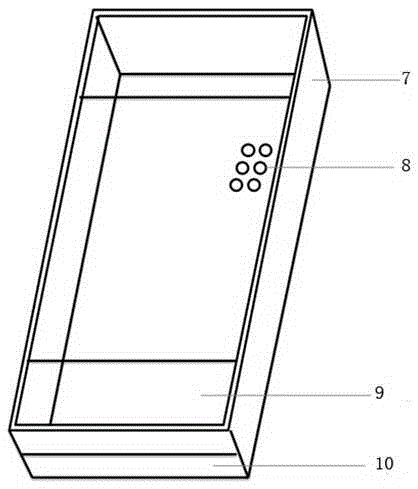

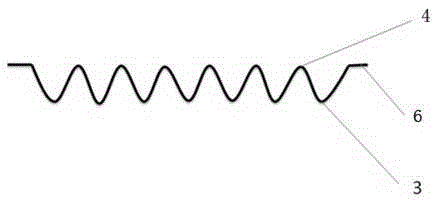

[0027] Process two sowing structures A and B with PVC material: the width of structure A is 28cm, and the thickness is 2mm. After leaving a plane 6 of 5mm on the side of structure A, the sowing area in the middle is processed as image 3 In the wave shape shown, the number of troughs 3 is 20, evenly distributed, the length of the troughs 3 is 57 cm, and the vertical distance between the peaks 4 and the troughs 3 is 1 cm. 40 sowing holes 5 are evenly processed in each trough 3, and the diameter of the sowing holes is 2.8 cm. The front and rear sides of the sowing area are respectively processed into a seed holding pool 2 with a width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com