Hand push type seeder

A seeder, hand-push technology, applied in the field of hand-push seeders, can solve the problems of low sowing efficiency and waste of labor, and achieve the effect of improving seeding efficiency and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

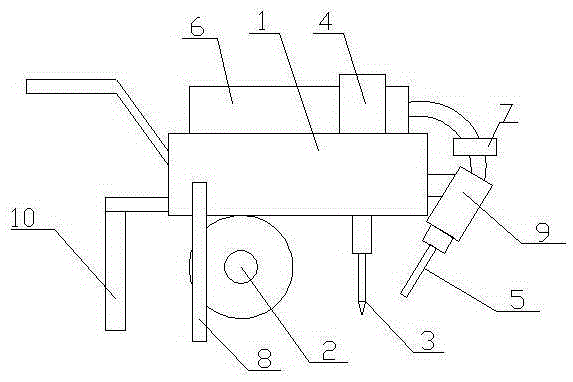

[0013] Such as figure 1 As shown, the present embodiment provides a hand-push seeder, including a body 1 and a support wheel 2, the support wheel 2 is arranged at the lower end of the body 1, and the front end of the body 1 is provided with a drilling head 3, and the drill The hole head 3 is driven by the drilling cylinder 4 provided at the upper end to drill holes, the hole head 3 is provided with a seeding pipe 5, the body 1 is provided with a seed storage bucket 6, and the seeding pipe 5 and the seed storage bucket 6 connections. The seeding pipe 5 is provided with a seed separator 7, and the seed number falling in the seeding pipe 5 is controlled by the seed separator 7. Both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com